Design of casting.pptx

Download as PPTX, PDF0 likes146 views

The document discusses several key design considerations for castings: 1) Variables like the metal properties, casting method, mold materials, and mold design influence casting quality. Proper design of gates, risers, and parting lines is important. 2) The part shape should allow for easy casting. The process, material, and properties should suit the part size and needs. 3) Features like fillets and avoiding concentrated metal at junctions can improve strength and prevent defects like blowholes. Designing areas in compression rather than tension also increases strength. External devices may be needed to handle unavoidable tensile stresses.

1 of 14

Download to read offline

Recommended

Design of castings and selection of the parting line

Design of castings and selection of the parting lineAnand Prithviraj

Ěý

General steps to be followed in the design of castings and the procedure to select the parting line in castings.Metal Casting.pptx

Metal Casting.pptxDr.M BALA THEJA

Ěý

Introduction

Selection of casting processes

General design considerations for casting

Casting tolerances

Simulation in casting design

Product design rules for sand casting

Patternallowancesinmetalcasting 140618172416-phpapp02

Patternallowancesinmetalcasting 140618172416-phpapp02Hadush Berhe

Ěý

Pattern allowances are extra material added to patterns to account for shrinkage and other factors during the casting process. Patterns are larger than the final casting size. Allowances include shrinkage allowance for metal contraction, machining allowance for finishing, and draft allowance so patterns can be easily removed from molds. Proper allowances and pattern design can minimize defects and costs in metal casting.Patternallowancesinmetalcasting 140618172416-phpapp02

Patternallowancesinmetalcasting 140618172416-phpapp02hadushberhe75

Ěý

Pattern allowances are extra material added to patterns to account for shrinkage and other factors during the casting process. Patterns are larger than the final casting size. Allowances include shrinkage allowance for metal contraction, machining allowance for finishing, and draft allowance so patterns can be easily removed from molds. Proper allowances and pattern design can reduce defects and costs in metal casting.Pattern allowances in metal casting

Pattern allowances in metal castingAndrés Escárraga

Ěý

Pattern allowances are extra material added to patterns to account for shrinkage and other factors during the casting process. Patterns are larger than the final casting size. Allowances include shrinkage allowance for metal contraction, machining allowance for finishing, and draft allowance so patterns can be easily removed from molds. Proper allowances and pattern design can minimize defects and costs in metal casting.2.casting process

2.casting processNarayanasamy Pandiarajan

Ěý

The document describes the casting process and its key terms. It discusses the main steps: pattern making, mould preparation including gating and risering, core making, melting and pouring, and cleaning and inspection. It provides details on each step and describes how a mould is made by packing sand around a pattern. Common components produced by casting are also listed, such as automobile and aircraft parts. Advantages include the ability to make complex shapes easily and economically, while limitations include potential defects and inferior properties compared to other processes.fundamental of metal sand casting processes

fundamental of metal sand casting processeslingerewenbakom

Ěý

The document discusses the fundamentals of metal casting, including the casting process, terminology used, factors that influence solidification and fluid flow of molten metal, heat transfer during solidification, and common casting defects. It describes the key steps of pattern making, mold making, pouring molten metal, solidification, and cleaning/inspection of cast parts. Terminology like cope, drag, risers, and gates are also defined.manufacturing technology -foundary

manufacturing technology -foundary Krishna Gali

Ěý

The document provides information on metal casting processes including definitions of key terms. It discusses the basic steps of metal casting which include making a pattern, preparing molds and cores, melting metal, pouring the molten metal into molds, solidification and cooling, removing and finishing the casting. Key sections include the foundry process, casting terms, pattern making, molding materials, melting and pouring, solidification, inspection and applications of casting.1

1Narayanasamy Pandiarajan

Ěý

The document discusses the casting process and its key terms. It describes the basic steps in making a casting which are (1) pattern making, (2) mould preparation including gating and risering, (3) core making, (4) melting and pouring, and (5) cleaning and inspection. It also lists some common components produced via casting such as automobile parts, aircraft turbine blades, pumps, valves and pipes. The advantages of casting include the ability to produce large and intricate shapes, suitability for mass production, uniform material properties, and low cost. Limitations include potential defects, unsuitability for small batches or thin sections.Design Consideration For Casting

Design Consideration For CastingMohit Joon

Ěý

The document discusses design considerations for castings. It notes that casting involves pouring molten material into a mold to create complex shapes. Successful casting requires controlling variables like the material, casting method, cooling rate, and gases. The document outlines design considerations like designing parts for easy casting, selecting suitable materials and processes, locating parting lines and gates, and including features like sprues and risers. It also discusses designing parts to avoid defects from things like shrinkage, stress concentrations, and uneven cooling. The document concludes by mentioning some common casting defects and factors in the economics of casting like costs of molds, materials, and production rates.Introduction to mp prathik

Introduction to mp prathikprathik jain

Ěý

This document provides information on casting processes and pattern making. It begins with an introduction and overview of casting classification and types of production systems. It then discusses specific casting processes like sand casting and rolling. Key factors for selecting a production process are outlined. The document also defines important terms in casting, describes the basic steps of making a casting, and lists common products made through casting. It discusses the casting process in detail, provides examples of components produced through casting, and notes advantages and limitations. Finally, it introduces pattern making, comparing patterns to castings, listing pattern functions and materials, and describing common pattern allowances.DFM casting.pptx

DFM casting.pptxPradeepNB2

Ěý

The document discusses design considerations for castings. It covers topics such as selecting a suitable casting process and material, designing the part for easy casting, locating gates and risers, avoiding defects, and economics. Key points include designing parts with uniform thickness and gradual changes to prevent shrinkage cavities, adding draft angles for removal from molds, and accounting for shrinkage and machining operations in patterns. Common defects like misruns, cold shuts and shrinkage cavities are also outlined. Economics depends on factors like materials, tooling, production rates and costs of melting, heat treating and inspection.The Manufacturing Processes - Foundary.pdf

The Manufacturing Processes - Foundary.pdfpgarg210405

Ěý

- Casting is a manufacturing process where molten metal is poured into a mold and allowed to solidify. It is one of the oldest manufacturing processes dating back 5000 years.

- There are two main categories of casting processes - those using expendable molds like sand casting and those using permanent metal molds. Molds are used to give shape and size to castings.

- Patterns are full-sized models of the desired casting shape, made slightly larger to account for shrinkage. There are different types of patterns like solid, split, loose-piece, and gated patterns used for different part geometries and production levels.Manufacturing Process - Casting

Manufacturing Process - CastingKhulna University of Engineering & Technology

Ěý

B.Sc. (Engineering)

Department of Mechanical Engineering

Khulna University of Engineering & Technology

Course - Manufacturing Process

Topic - Casting

Manufacturing

ManufacturingMohamed Mohamed El-Sayed

Ěý

The document discusses various manufacturing processes used in mechanical engineering. It covers primary shaping processes like casting and forging, machining processes, surface finishing processes, and joining processes. It then describes specific processes in more detail, including casting methods like sand casting and die casting. It also discusses hot working processes like hot rolling, hot forging, and extrusion which shape metals above their recrystallization temperature, as well as cold working processes below that temperature like cold rolling. Cold working increases strength and hardness but reduces ductility.metal Forming

metal Forming BhargavDave18

Ěý

This document provides an overview of various metal forming processes including forging, rolling, extrusion, and drawing. It discusses topics such as the stages of impression die forging, load-stroke curves in closed-die forging, flat and shape rolling processes, defects in flat rolling, ring rolling, types of extrusion and defects like chevron cracking, variables in drawing, and forming processes used for rocket casings. The document contains illustrations of many metal forming techniques and operations.0.Unit 3.pptx

0.Unit 3.pptxSureshkannanV1

Ěý

The document discusses various sheet metal processes including shearing, punching, blanking, bending, drawing, spinning, and forming. It provides details on each process such as the basic setup, how it works, applications, advantages, and equations to calculate forces required. Key points covered include how shearing produces rough cut edges, the importance of proper clearance in punching, the stages of deep drawing including thinning, and how spinning can form axisymmetric shapes through localized deformation.casting notes mpya.pptx

casting notes mpya.pptxEmmanuelMatutu1

Ěý

The document discusses casting manufacturing processes and patterns. It provides an overview of casting, including definitions and key terms. The main steps in the casting process are described as well as common applications. Pattern materials and types are also outlined. Patterns are replicas used to form mold cavities and can be single-piece, split, loose-piece, or other types depending on the part geometry and needed access. Wood, metal, plastic and other materials can be used for patterns.castingprocessmetalccccc-161223050424.ppt

castingprocessmetalccccc-161223050424.pptPraveen Kumar

Ěý

Casting is one of the oldest metal shaping techniques known, involving pouring molten metal into a mold cavity. There are six basic steps in the casting process: (1) creating a pattern in sand to form the mold cavity, (2) incorporating the pattern and sand into a gating system, (3) removing the pattern, (4) filling the mold with molten metal, (5) allowing the metal to cool, and (6) breaking away the sand mold and removing the casting. Common casting materials include cast iron, aluminum, and bronze. Casting allows for complex shapes and is well-suited for mass production. However, it involves some labor and may not achieve high dimensional accuracy.Special Casting Processes.pptx

Special Casting Processes.pptxBopal, Ahmedabad.

Ěý

Special Casting Processes

Centrifugal Casting

Semi centrifugal casting

Centrifuging

Die Casting

Gravity Die Casting

Pressure die casting

Hot chamber die-casting:

Submerged plunger die casting

Air blown or goose neck die casting machine

Investment Casting

Defects in Casting

Blow holes Casting Defects

Shrinkage

Crack

Inclusions

Lift and shift

Swell

Fins

Misrun and cold shut

Metal Penetration

Hard spot

Run out

Drop

Warpagecastingprocesscastiron-161223050424 (1).ppt

castingprocesscastiron-161223050424 (1).pptPraveen Kumar

Ěý

The document discusses casting processes and provides details about casting terminology, the casting process steps, advantages and disadvantages of casting, applications of casting, pattern materials and types of patterns, molding sand types, and mould terminology. It describes the basic casting process as pouring molten metal into a refractory mold and allowing it to solidify. The key steps are making a pattern, incorporating it into a gating system, removing the pattern, filling the mold with molten metal, allowing it to cool, and removing the casting. Common casting applications include engine blocks, crankshafts, and turbine vanes.Manufacturing Engineering,Sheet Metal Forming

Manufacturing Engineering,Sheet Metal FormingZeradam Yeshiwas

Ěý

Manufacturing Engineering II, The slide lecture is including various sheet metal forming processes.

Zeradam Yeshiwas

Ethiopiaeffect of manufacturing processes on design

effect of manufacturing processes on design9784

Ěý

The document discusses various manufacturing processes and considerations for component design based on the selected process. It describes primary, secondary and tertiary manufacturing processes and provides details on casting, forging and sheet metal processes. Key factors for casting include part complexity, material properties and economics of production quantities. For forging, important considerations include parting lines, draft angles, fillets and corners to enable uniform metal flow. Sheet metal design must account for material thickness and formability limitations.Manufacturing.ppt

Manufacturing.pptPraveen Kumar

Ěý

This document provides an overview and introduction to manufacturing processes. It discusses the different types of manufacturing industries and classifies them as primary, secondary, or tertiary. Manufacturing processes are categorized as either processing or assembly. Processing operations are further broken down into shaping, property enhancing, and surface processing. Common shaping processes discussed include casting, forming, machining, joining, and heat treatment. The document provides examples of specific processes within each of these categories such as sand casting, rolling, turning, and welding.Die casting and types

Die casting and typesUmair Raza

Ěý

1. The document discusses various metal casting processes, focusing on sand casting and die casting.

2. Sand casting involves pouring molten metal into a mold made of sand. Die casting uses molds made from two hardened steel dies and forces molten metal in under high pressure.

3. Both processes involve pouring molten metal into a mold and allowing it to solidify, then breaking the mold away to retrieve the casting. Sand casting is best for medium and large parts while die casting produces large quantities of small to medium parts.UNIT3-Special casting processmechanical.ppt

UNIT3-Special casting processmechanical.pptPraveen Kumar

Ěý

This document discusses various special casting processes including centrifugal casting, die casting, and investment casting. It provides details on:

1. Centrifugal casting can produce hollow cylindrical castings and has three main types - true, semi, and centrifuging. It works by pouring molten metal into a revolving mold.

2. Die casting uses metal dies to force molten metal into a mold cavity under high pressure. There are gravity and pressure die casting, with hot and cold chamber variations.

3. Investment casting, also called lost-wax casting, involves making a wax pattern, coating it, embedding in a refractory material, melting out the wax, and pouring molten metal. It producesManufacturing Process -.pptx

Manufacturing Process -.pptxNIHALMENARIA

Ěý

This document discusses various metal forming processes including rolling, extrusion, forging, and drawing. It provides definitions and descriptions of each process. Rolling involves passing metal through rotating rolls to reduce thickness or shape it. Extrusion uses a press to force heated metal through a die to shape it. Forging shapes heated metal by compressing it with dies or hammers. Drawing shapes metal by pulling it through a die to reduce its cross-sectional area. Each process deforms metal through compression or tension to form parts.Renewable energy engineering with reference to VAWT,HAWT, Biomass

Renewable energy engineering with reference to VAWT,HAWT, Biomassprasannabhagwat3

Ěý

Discussion on Renewable energy engineering, VWAT, HWAT and Biomass conversion processIntroduction to Hybrid Machining Processes.pptx

Introduction to Hybrid Machining Processes.pptxprasannabhagwat3

Ěý

This document discusses various hybrid machining processes. It defines hybrid processes as combining two or more manufacturing processes to produce parts more efficiently. There are two main types of hybrid processes: assisted processes where one process directly removes material while another assists, and combined processes where multiple processes directly remove material. Examples of assisted processes discussed include vibration assisted grinding and EDM, laser assisted turning and ECM, and magnetic field assisted EDM. Combined hybrid processes discussed are electrochemical grinding which combines ECM and grinding. The document provides details on the working and benefits of several key hybrid machining techniques.More Related Content

Similar to Design of casting.pptx (20)

1

1Narayanasamy Pandiarajan

Ěý

The document discusses the casting process and its key terms. It describes the basic steps in making a casting which are (1) pattern making, (2) mould preparation including gating and risering, (3) core making, (4) melting and pouring, and (5) cleaning and inspection. It also lists some common components produced via casting such as automobile parts, aircraft turbine blades, pumps, valves and pipes. The advantages of casting include the ability to produce large and intricate shapes, suitability for mass production, uniform material properties, and low cost. Limitations include potential defects, unsuitability for small batches or thin sections.Design Consideration For Casting

Design Consideration For CastingMohit Joon

Ěý

The document discusses design considerations for castings. It notes that casting involves pouring molten material into a mold to create complex shapes. Successful casting requires controlling variables like the material, casting method, cooling rate, and gases. The document outlines design considerations like designing parts for easy casting, selecting suitable materials and processes, locating parting lines and gates, and including features like sprues and risers. It also discusses designing parts to avoid defects from things like shrinkage, stress concentrations, and uneven cooling. The document concludes by mentioning some common casting defects and factors in the economics of casting like costs of molds, materials, and production rates.Introduction to mp prathik

Introduction to mp prathikprathik jain

Ěý

This document provides information on casting processes and pattern making. It begins with an introduction and overview of casting classification and types of production systems. It then discusses specific casting processes like sand casting and rolling. Key factors for selecting a production process are outlined. The document also defines important terms in casting, describes the basic steps of making a casting, and lists common products made through casting. It discusses the casting process in detail, provides examples of components produced through casting, and notes advantages and limitations. Finally, it introduces pattern making, comparing patterns to castings, listing pattern functions and materials, and describing common pattern allowances.DFM casting.pptx

DFM casting.pptxPradeepNB2

Ěý

The document discusses design considerations for castings. It covers topics such as selecting a suitable casting process and material, designing the part for easy casting, locating gates and risers, avoiding defects, and economics. Key points include designing parts with uniform thickness and gradual changes to prevent shrinkage cavities, adding draft angles for removal from molds, and accounting for shrinkage and machining operations in patterns. Common defects like misruns, cold shuts and shrinkage cavities are also outlined. Economics depends on factors like materials, tooling, production rates and costs of melting, heat treating and inspection.The Manufacturing Processes - Foundary.pdf

The Manufacturing Processes - Foundary.pdfpgarg210405

Ěý

- Casting is a manufacturing process where molten metal is poured into a mold and allowed to solidify. It is one of the oldest manufacturing processes dating back 5000 years.

- There are two main categories of casting processes - those using expendable molds like sand casting and those using permanent metal molds. Molds are used to give shape and size to castings.

- Patterns are full-sized models of the desired casting shape, made slightly larger to account for shrinkage. There are different types of patterns like solid, split, loose-piece, and gated patterns used for different part geometries and production levels.Manufacturing Process - Casting

Manufacturing Process - CastingKhulna University of Engineering & Technology

Ěý

B.Sc. (Engineering)

Department of Mechanical Engineering

Khulna University of Engineering & Technology

Course - Manufacturing Process

Topic - Casting

Manufacturing

ManufacturingMohamed Mohamed El-Sayed

Ěý

The document discusses various manufacturing processes used in mechanical engineering. It covers primary shaping processes like casting and forging, machining processes, surface finishing processes, and joining processes. It then describes specific processes in more detail, including casting methods like sand casting and die casting. It also discusses hot working processes like hot rolling, hot forging, and extrusion which shape metals above their recrystallization temperature, as well as cold working processes below that temperature like cold rolling. Cold working increases strength and hardness but reduces ductility.metal Forming

metal Forming BhargavDave18

Ěý

This document provides an overview of various metal forming processes including forging, rolling, extrusion, and drawing. It discusses topics such as the stages of impression die forging, load-stroke curves in closed-die forging, flat and shape rolling processes, defects in flat rolling, ring rolling, types of extrusion and defects like chevron cracking, variables in drawing, and forming processes used for rocket casings. The document contains illustrations of many metal forming techniques and operations.0.Unit 3.pptx

0.Unit 3.pptxSureshkannanV1

Ěý

The document discusses various sheet metal processes including shearing, punching, blanking, bending, drawing, spinning, and forming. It provides details on each process such as the basic setup, how it works, applications, advantages, and equations to calculate forces required. Key points covered include how shearing produces rough cut edges, the importance of proper clearance in punching, the stages of deep drawing including thinning, and how spinning can form axisymmetric shapes through localized deformation.casting notes mpya.pptx

casting notes mpya.pptxEmmanuelMatutu1

Ěý

The document discusses casting manufacturing processes and patterns. It provides an overview of casting, including definitions and key terms. The main steps in the casting process are described as well as common applications. Pattern materials and types are also outlined. Patterns are replicas used to form mold cavities and can be single-piece, split, loose-piece, or other types depending on the part geometry and needed access. Wood, metal, plastic and other materials can be used for patterns.castingprocessmetalccccc-161223050424.ppt

castingprocessmetalccccc-161223050424.pptPraveen Kumar

Ěý

Casting is one of the oldest metal shaping techniques known, involving pouring molten metal into a mold cavity. There are six basic steps in the casting process: (1) creating a pattern in sand to form the mold cavity, (2) incorporating the pattern and sand into a gating system, (3) removing the pattern, (4) filling the mold with molten metal, (5) allowing the metal to cool, and (6) breaking away the sand mold and removing the casting. Common casting materials include cast iron, aluminum, and bronze. Casting allows for complex shapes and is well-suited for mass production. However, it involves some labor and may not achieve high dimensional accuracy.Special Casting Processes.pptx

Special Casting Processes.pptxBopal, Ahmedabad.

Ěý

Special Casting Processes

Centrifugal Casting

Semi centrifugal casting

Centrifuging

Die Casting

Gravity Die Casting

Pressure die casting

Hot chamber die-casting:

Submerged plunger die casting

Air blown or goose neck die casting machine

Investment Casting

Defects in Casting

Blow holes Casting Defects

Shrinkage

Crack

Inclusions

Lift and shift

Swell

Fins

Misrun and cold shut

Metal Penetration

Hard spot

Run out

Drop

Warpagecastingprocesscastiron-161223050424 (1).ppt

castingprocesscastiron-161223050424 (1).pptPraveen Kumar

Ěý

The document discusses casting processes and provides details about casting terminology, the casting process steps, advantages and disadvantages of casting, applications of casting, pattern materials and types of patterns, molding sand types, and mould terminology. It describes the basic casting process as pouring molten metal into a refractory mold and allowing it to solidify. The key steps are making a pattern, incorporating it into a gating system, removing the pattern, filling the mold with molten metal, allowing it to cool, and removing the casting. Common casting applications include engine blocks, crankshafts, and turbine vanes.Manufacturing Engineering,Sheet Metal Forming

Manufacturing Engineering,Sheet Metal FormingZeradam Yeshiwas

Ěý

Manufacturing Engineering II, The slide lecture is including various sheet metal forming processes.

Zeradam Yeshiwas

Ethiopiaeffect of manufacturing processes on design

effect of manufacturing processes on design9784

Ěý

The document discusses various manufacturing processes and considerations for component design based on the selected process. It describes primary, secondary and tertiary manufacturing processes and provides details on casting, forging and sheet metal processes. Key factors for casting include part complexity, material properties and economics of production quantities. For forging, important considerations include parting lines, draft angles, fillets and corners to enable uniform metal flow. Sheet metal design must account for material thickness and formability limitations.Manufacturing.ppt

Manufacturing.pptPraveen Kumar

Ěý

This document provides an overview and introduction to manufacturing processes. It discusses the different types of manufacturing industries and classifies them as primary, secondary, or tertiary. Manufacturing processes are categorized as either processing or assembly. Processing operations are further broken down into shaping, property enhancing, and surface processing. Common shaping processes discussed include casting, forming, machining, joining, and heat treatment. The document provides examples of specific processes within each of these categories such as sand casting, rolling, turning, and welding.Die casting and types

Die casting and typesUmair Raza

Ěý

1. The document discusses various metal casting processes, focusing on sand casting and die casting.

2. Sand casting involves pouring molten metal into a mold made of sand. Die casting uses molds made from two hardened steel dies and forces molten metal in under high pressure.

3. Both processes involve pouring molten metal into a mold and allowing it to solidify, then breaking the mold away to retrieve the casting. Sand casting is best for medium and large parts while die casting produces large quantities of small to medium parts.UNIT3-Special casting processmechanical.ppt

UNIT3-Special casting processmechanical.pptPraveen Kumar

Ěý

This document discusses various special casting processes including centrifugal casting, die casting, and investment casting. It provides details on:

1. Centrifugal casting can produce hollow cylindrical castings and has three main types - true, semi, and centrifuging. It works by pouring molten metal into a revolving mold.

2. Die casting uses metal dies to force molten metal into a mold cavity under high pressure. There are gravity and pressure die casting, with hot and cold chamber variations.

3. Investment casting, also called lost-wax casting, involves making a wax pattern, coating it, embedding in a refractory material, melting out the wax, and pouring molten metal. It producesManufacturing Process -.pptx

Manufacturing Process -.pptxNIHALMENARIA

Ěý

This document discusses various metal forming processes including rolling, extrusion, forging, and drawing. It provides definitions and descriptions of each process. Rolling involves passing metal through rotating rolls to reduce thickness or shape it. Extrusion uses a press to force heated metal through a die to shape it. Forging shapes heated metal by compressing it with dies or hammers. Drawing shapes metal by pulling it through a die to reduce its cross-sectional area. Each process deforms metal through compression or tension to form parts.More from prasannabhagwat3 (7)

Renewable energy engineering with reference to VAWT,HAWT, Biomass

Renewable energy engineering with reference to VAWT,HAWT, Biomassprasannabhagwat3

Ěý

Discussion on Renewable energy engineering, VWAT, HWAT and Biomass conversion processIntroduction to Hybrid Machining Processes.pptx

Introduction to Hybrid Machining Processes.pptxprasannabhagwat3

Ěý

This document discusses various hybrid machining processes. It defines hybrid processes as combining two or more manufacturing processes to produce parts more efficiently. There are two main types of hybrid processes: assisted processes where one process directly removes material while another assists, and combined processes where multiple processes directly remove material. Examples of assisted processes discussed include vibration assisted grinding and EDM, laser assisted turning and ECM, and magnetic field assisted EDM. Combined hybrid processes discussed are electrochemical grinding which combines ECM and grinding. The document provides details on the working and benefits of several key hybrid machining techniques.Introduction to Surface Treatments Case Hardening.pptx

Introduction to Surface Treatments Case Hardening.pptxprasannabhagwat3

Ěý

The document discusses various surface hardening processes. It describes the general hardening process which involves heating steel above critical temperatures, quenching, and tempering. Specific processes covered include flame hardening, induction hardening, electron beam hardening, and the three principal case hardening processes: carburizing, cyaniding, and nitriding. Carburizing can be done via pack, liquid, or gas methods and is used to enrich the surface of low-carbon steel with carbon. Nitriding differs in that it does not require quenching.Introduction to jigs and fixtures.ppt

Introduction to jigs and fixtures.pptprasannabhagwat3

Ěý

1. Jigs guide cutting tools and hold workpieces for machining, while fixtures only hold workpieces.

2. The document discusses the 3-2-1 locating principle for precisely positioning workpieces using three points in one plane, two in another, and one in a third.

3. Key considerations in jig and fixture design include locating points, reducing idle time, using hardened materials, and incorporating foolproofing to ensure correct positioning.Riser Design Methods (2).pptx

Riser Design Methods (2).pptxprasannabhagwat3

Ěý

Riser Design Methods

This document discusses different methods for designing risers for castings, including Caine's method, the modulus method, and the shape factor method. Caine's method uses freezing ratios to determine appropriate riser sizes based on surface area to volume ratios of the casting and riser. The modulus method compares the moduli of the casting and riser. The shape factor method uses a casting's shape factor and desired freezing ratio to determine the required riser volume. Sample problems demonstrate applying each method to calculate riser dimensions and volumes.METAL CASTING.pptx

METAL CASTING.pptxprasannabhagwat3

Ěý

This document provides an overview of metal casting processes and concepts. It discusses the key steps: melting metal, pouring it into a mold, and allowing it to solidify. Molds can be open or closed and made of materials like sand or metal. The document also covers solidification of pure metals and alloys, shrinkage during cooling, and the use of risers to compensate for shrinkage. Chvorinov's rule is presented as a way to calculate solidification times based on a casting's volume-to-surface area ratio.Recently uploaded (20)

How to Build a Maze Solving Robot Using Arduino

How to Build a Maze Solving Robot Using ArduinoCircuitDigest

Ěý

Learn how to make an Arduino-powered robot that can navigate mazes on its own using IR sensors and "Hand on the wall" algorithm.

This step-by-step guide will show you how to build your own maze-solving robot using Arduino UNO, three IR sensors, and basic components that you can easily find in your local electronics shop.Wireless-Charger presentation for seminar .pdf

Wireless-Charger presentation for seminar .pdfAbhinandanMishra30

Ěý

Wireless technology used in chargerThe Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ěý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

decarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

Ěý

Webinar Decarbonization steel industryOptimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ěý

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. Introduction to Safety, Health & Environment

Introduction to Safety, Health & Environmentssuserc606c7

Ěý

Introduction to

Safety, Health &EnvironmentIntegration of Additive Manufacturing (AM) with IoT : A Smart Manufacturing A...

Integration of Additive Manufacturing (AM) with IoT : A Smart Manufacturing A...ASHISHDESAI85

Ěý

Combining 3D printing with Internet of Things (IoT) enables the creation of smart, connected, and customizable objects that can monitor, control, and optimize their performance, potentially revolutionizing various industries. oT-enabled 3D printers can use sensors to monitor the quality of prints during the printing process. If any defects or deviations from the desired specifications are detected, the printer can adjust its parameters in real time to ensure that the final product meets the required standards.How to Make an RFID Door Lock System using Arduino

How to Make an RFID Door Lock System using ArduinoCircuitDigest

Ěý

Learn how to build an RFID-based door lock system using Arduino to enhance security with contactless access control.UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptx

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxKesavanT10

Ěý

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxUS Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load Current Delay which delays the creation and storage of created Electromagnetic Field Energy around the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads, additional Input Power must be supplied to the Prime Mover and additional Mechanical Input Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator, an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1 MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the system.IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...ssuserd9338b

Ěý

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Control for Printed Board Assemblies.pdfOptimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ěý

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Design of casting.pptx

- 1. Design of casting Unit III

- 2. Design Consideration for castings • Variables in Casting process: characteristics of the metals (or alloys) casts, method of casting, mold/die materials, mold/die design. • • The flow of the molten metal in the mold cavities, the gating systems, the rateof cooling, and the gases evolved all influence the quality of a casting

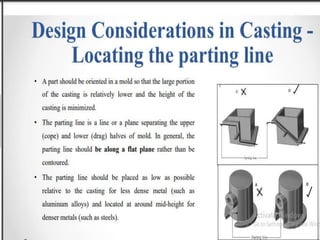

- 3. Design Considerations in Casting • Design the part so that the shape is cast easily. • Select a casting process and material suitable for the part, size, mechanical properties, etc. • Locate the parting line of the mold in the part. • Locate and design the gates to allow uniform feeding of the mold cavity with molten metal. • Select an appropriate runner geometry for the system. • Locate mold features such as sprue, screens and risers, as appropriate. • Make sure proper controls and good practices are in place

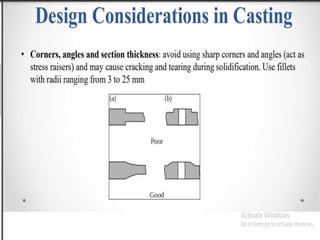

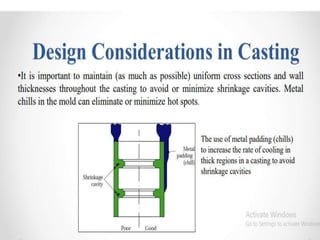

- 4. Design Considerations in Casting

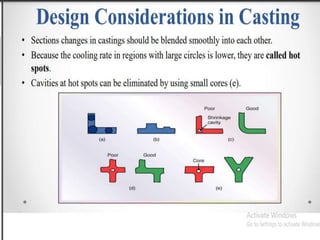

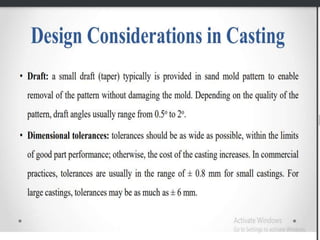

- 5. Design Considerations in Casting

- 9. Design Consideration for castings • Provision of Fillet Radius Round All External Corners, it has two advantages - it increases the endurance limit of the component and reduces the formation of brittle chilled edges. When the metal in the corner cools faster than the metal adjacent to the corner, brittle chilled edges are formed due to iron carbide

- 10. Design Consideration for castings

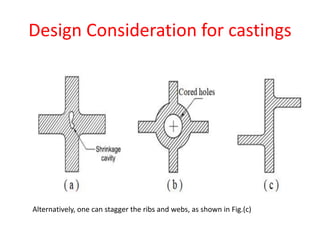

- 11. Design Consideration for castings • Avoid Concentration of Metal at the Junctions • At the junction as shown there is a concentration of metal. Even after the metal on the surface solidifies, the central portion still remains in the molten stage, with the result that a shrinkage cavity or blowhole may appear at the centre as shown in fig (a). • There are two ways to avoid the concentration of metal. One is to provide a cored opening in webs and ribs, as shown in Fig. (b).

- 12. Design Consideration for castings Alternatively, one can stagger the ribs and webs, as shown in Fig.(c)

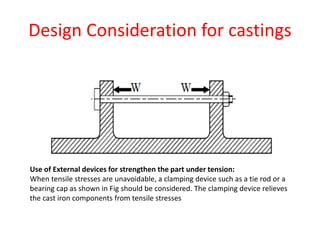

- 13. Design Consideration for castings Design of component in compression than in tension. Always Keep the Stressed Areas of the Part in Compression Cast iron has more compressive strength than its tensile strength. Hence, design the component such that the stressed area become under compression for the better performance

- 14. Design Consideration for castings Use of External devices for strengthen the part under tension: When tensile stresses are unavoidable, a clamping device such as a tie rod or a bearing cap as shown in Fig should be considered. The clamping device relieves the cast iron components from tensile stresses