Design of gating systems

- 1. DESIGN OF GATING SYSTEMS MADE BY VAIBHAV PATHAK MECHANICAL B.TECH 3rd YEAR

- 2. The main function of gating system is to lead clean molten metal from ladle to the casting cavity ensuring smooth, uniform and complete filling. The flow of molten metal after being poured is a transient phenomena accompanied by : ŌĆó Turbulence, ŌĆó Separation of the flow from the boundaries, ŌĆó Dividing and combined flow at the junction, ŌĆó Simultaneous heat transfer during the flow and onset of solidification. INTRODUCTION

- 3. ŌĆó Experimentation through trial and error methods for a given casting geometry. ŌĆó Mathematical model. METHODS TO DESIGN AN OPTIMIZED GATE

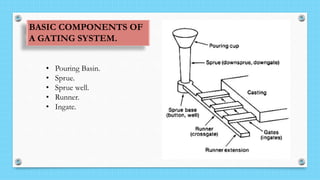

- 4. BASIC COMPONENTS OF A GATING SYSTEM. ŌĆó Pouring Basin. ŌĆó Sprue. ŌĆó Sprue well. ŌĆó Runner. ŌĆó Ingate.

- 5. POURING BASIN. It is the funnel-shaped opening, made at the top of the mold. The main purpose of the pouring basin is to direct the flow of molten metal from ladle to the sprue. . SPRUE WELL. It is located at the base of the sprue. It arrests the free fall of molten metal through the sprue and turns it by a right angle towards the runner and also acts as a reservoir for the runners and gates as they fill.

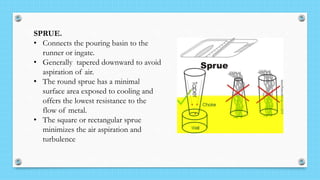

- 6. SPRUE. ŌĆó Connects the pouring basin to the runner or ingate. ŌĆó Generally tapered downward to avoid aspiration of air. ŌĆó The round sprue has a minimal surface area exposed to cooling and offers the lowest resistance to the flow of metal. ŌĆó The square or rectangular sprue minimizes the air aspiration and turbulence

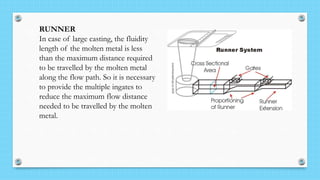

- 7. RUNNER In case of large casting, the fluidity length of the molten metal is less than the maximum distance required to be travelled by the molten metal along the flow path. So it is necessary to provide the multiple ingates to reduce the maximum flow distance needed to be travelled by the molten metal.

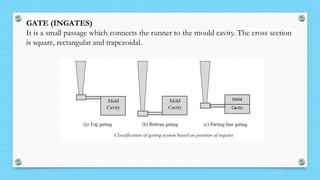

- 8. GATE (INGATES) It is a small passage which connects the runner to the mould cavity. The cross section is square, rectangular and trapezoidal.

- 9. GUIDELINES TO DESIGN A GATING SYSTEM ŌĆó The size of the sprue fixes the flow rate. ŌĆó The sprue should be located at certain distance from the gates so as to minimize velocity of molten metal at ingates. ŌĆó Rectangular cross-section sprue is better than circular one with the same cross-sectional area, since critical velocity for turbulence is much less for circular sections. ŌĆó In addition, vortex formation tendency in a sprue with circular cross section is higher.

- 10. ŌĆó Sprue should be tapered by approximately 5% minimum to avoid aspiration of the air and free fall of the metal. ŌĆó Ingates should be located in thick regions. ŌĆó Multiple gating is frequently desirable. ŌĆó Rectangular cross section of runners and ingates are generally preferred in sand castings.

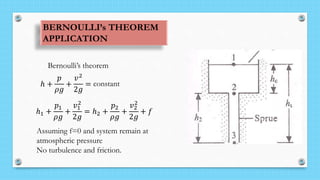

- 11. BERNOULLIŌĆÖs THEOREM APPLICATION BernoulliŌĆÖs theorem ŌäÄ + ØæØ Ø£īØæö + ØæŻ2 2Øæö = constant ŌäÄ1 + ØæØ1 Ø£īØæö + ØæŻ1 2 2Øæö = ŌäÄ2 + ØæØ2 Ø£īØæö + ØæŻ2 2 2Øæö + Øæō Assuming f=0 and system remain at atmospheric pressure No turbulence and friction.

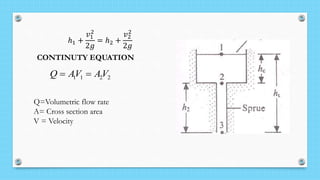

- 12. ŌäÄ1 + ØæŻ1 2 2Øæö = ŌäÄ2 + ØæŻ2 2 2Øæö CONTINUTY EQUATION 1 1 2 2Q AV AV’ĆĮ ’ĆĮ Q=Volumetric flow rate A= Cross section area V = Velocity

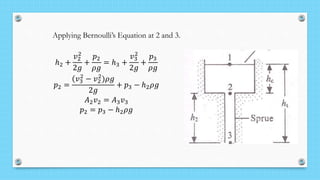

- 13. Applying BernoulliŌĆÖs Equation at 2 and 3. ŌäÄ2 + ØæŻ2 2 2Øæö + ØæØ2 Ø£īØæö = ŌäÄ3 + ØæŻ3 2 2Øæö + ØæØ3 Ø£īØæö ØæØ2 = ØæŻ3 2 ŌłÆ ØæŻ2 2 )Ø£īØæö 2Øæö + ØæØ3 ŌłÆ ŌäÄ2 Ø£īØæö ØÉ┤2 ØæŻ2 = ØÉ┤3 ØæŻ3 ØæØ2 = ØæØ3 ŌłÆ ŌäÄ2 Ø£īØæö

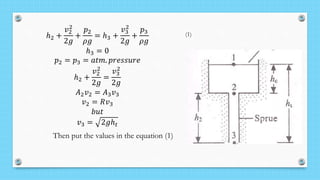

- 14. ŌäÄ2 + ØæŻ2 2 2Øæö + ØæØ2 Ø£īØæö = ŌäÄ3 + ØæŻ3 2 2Øæö + ØæØ3 Ø£īØæö ŌäÄ3 = 0 ØæØ2 = ØæØ3 = ØæÄØæĪØæÜ. ØæØØæ¤ØæÆØæĀØæĀØæóØæ¤ØæÆ ŌäÄ2 + ØæŻ2 2 2Øæö = ØæŻ3 2 2Øæö ØÉ┤2 ØæŻ2 = ØÉ┤3 ØæŻ3 ØæŻ2 = ØæģØæŻ3 ØæÅØæóØæĪ ØæŻ3 = 2ØæöŌäÄ ØæĪ Then put the values in the equation (1) (1)

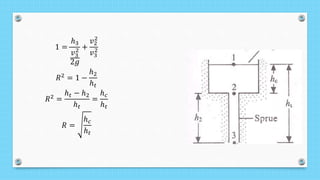

- 15. 1 = ŌäÄ3 ØæŻ3 2 2Øæö + ØæŻ2 2 ØæŻ3 2 Øæģ2 = 1 ŌłÆ ŌäÄ2 ŌäÄ ØæĪ Øæģ2 = ŌäÄ ØæĪ ŌłÆ ŌäÄ2 ŌäÄ ØæĪ = ŌäÄ ØæÉ ŌäÄ ØæĪ Øæģ = ŌäÄ ØæÉ ŌäÄ ØæĪ

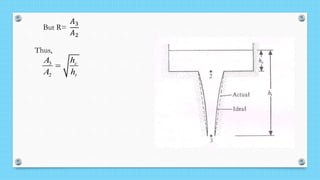

- 16. But R= ØÉ┤3 ØÉ┤2 3 2 c t A h A h ’ĆĮ Thus,

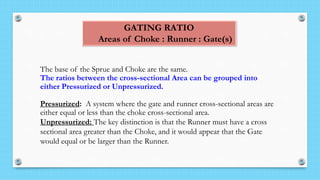

- 17. The base of the Sprue and Choke are the same. The ratios between the cross-sectional Area can be grouped into either Pressurized or Unpressurized. Pressurized: A system where the gate and runner cross-sectional areas are either equal or less than the choke cross-sectional area. Unpressurized: The key distinction is that the Runner must have a cross sectional area greater than the Choke, and it would appear that the Gate would equal or be larger than the Runner. GATING RATIO Areas of Choke : Runner : Gate(s)