Dewatering Pump Presentation - By: Terry Aylward

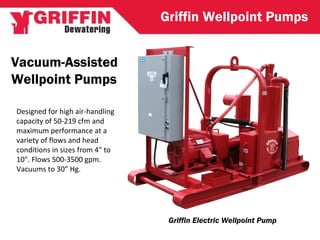

- 2. Griffin Wellpoint Pumps Griffin Electric Wellpoint Pump Designed for high air-handling capacity of 50-219 cfm and maximum performance at a variety of flows and head conditions in sizes from 4" to 10". Flows 500-3500 gpm. Vacuums to 30ŌĆØ Hg. Vacuum-Assisted Wellpoint Pumps

- 3. Building Team/Key Players: EMJ Construction General Contractor ŌĆō Chattanooga, TN, Griffin Dewatering Southwest, LLC Sub Contractor ŌĆō Houston, TX A Wellpoint System was used for the construction of a detention pond at the Pearland Town Center in Pearland, Texas Griffin Wellpoint Pumps

- 5. Griffin Non-Clog Pumps Suited to meet all of your bypass, sumping and dewatering needs in sizes ranging from 4" to 16". Handles air volumes from 50 to 150 cfm and solids up to 3". Flows 500- 12000 gpm. Designed with two or three port non-clog impellers. Variable-Use Vacuum-Assisted Non-Clog Pumps

- 6. Griffin Non-Clog Pumps Griffin (model 16ncrd) non-clog pumps powered by 12 cylinder engines each capable of pumping 12,000 gallons per minute These two pumps are in the field at the Olmsted Lock and Dam in Southern Illinois, near Missouri and Kentucky in close proximity to the Ohio River. Bypass project in New Mexico with 18 in non-clog pump. The project consists of repairing an existing manhole 48ŌĆØ sewer line. The bypass is approximately 1,200 LF from a temporary manhole to another manhole inside the treatment plant.

- 7. Griffin Non-Clog Pumps Non-Clog Pumps handle debris up to 4.5ŌĆØ and feature a clean out / inspection port for hassle-free removal of larger debris thatŌĆÖs easily visible in the inspection port, and can be removed.

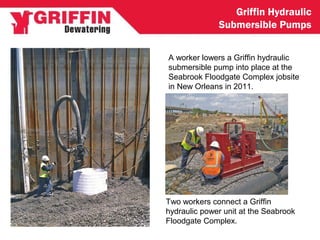

- 8. Griffin Hydraulic Submersible Pumps Hydraulic Driven Submersible Pumps and Power Units Available from 4" to 24" in a variety of configurations for material handling, trash handling and axial flow applications. Flows 300-20000 gpm.

- 9. Lake Isabella Bypass Griffin axial flow pumps on Lake Isabella. Fed by the Kern River, the lake is a primary source of water for farmers in the southern part of the largest agricultural area in California. Griffin Dewatering Corporation was called in to design, construct, and operate a temporary pump station that would run for five months. The station was capable of pumping 200,000 gallons per minute (gpm) with a standby capacity of 30,000 gpm. The quantity the station actually pumped was dependent upon the demand downstream. Location: High in the desert mountains above Bakersfield, California and San Joaquin Valley. General Contractor: Griffin Dewatering Farwest Owner: Isabella Partners Griffin Hydraulic Submersible Pumps

- 10. Griffin Hydraulic Submersible Pumps A worker lowers a Griffin hydraulic submersible pump into place at the Seabrook Floodgate Complex jobsite in New Orleans in 2011. Two workers connect a Griffin hydraulic power unit at the Seabrook Floodgate Complex.

- 11. Griffin Silent Pumps Wherever maximum performance with minimal noise is required, Griffin Silent Pumps are a proven solution. GriffinŌĆÖs silent pumps are available in a wide variety of models for multiple types of applications such as sewer bypass, wellpoints and sumping. Units are designed to provide a quiet operation where pumping is required and noise must be kept to a minimum.

- 12. Griffin Silent Pumps GriffinŌĆÖs Silent Pump Units are designed to provide quiet operation where pumping is required and noise must be kept to a minimum. The Silent Pac enclosure is engineered for durability, ease of operations and maintenance. The noise level of the Silent Pump is less than 70 decibels at 23 feet. The enclosure has doors that allow for easy access to operating controls and for regular maintenance.

- 13. Griffin Trash Pumps Griffin's Self Priming Trash Pumps are available in 4" and 6" models standard that do not require additional priming systems. These pumps are wet-priming portable pumps. They operate efficiently under intermittent flow conditions. These pumps are capable of handling high flows and head conditions exceeding 125 ft. The pump includes a suction flapper to prime and reprime at suction lifts of 25 ft. and greater. The impellers can handle solids up to 3" and larger.

- 14. Griffin Trash Pumps These pumps are available in diesel or electric models with an integral fuel tank or trailer mounted. Self-Contained, diesel-driven, self-priming, trash pump Operates efficiently at a wide range of conditions Able to pass 3" solids Rugged, quality construction Self-priming pump does not require additional priming system such as vacuum pump or compressors Available as skid or trailer mounted Easy access large cleanout

- 15. Griffin Jet Pumps Standard 4" and 6" jet pumps provide you with the source to jet your wellpoint system or other high pressure applications. Pressure 80-350 psi. High Pressure Jet Pumps

- 16. Griffin Jet Pumps ’é¦Use on a variety of applications requiring high pressure flow for jetting wellpoints, well casings or pilings. ’é¦Variety of seal configurations available - conical seal, mechanical seal or packing. ’é¦End suction centrifugal pumps ’é¦Hand primers standard; automatic primers are available ’é¦Integral fuel tank designed for 24 hour operation ’é¦Trailer mounted versions available

- 17. Griffin Jet Pumps These jet pumps are capable of delivering flow over 1,400 gpm and head conditions up to 900 ft. The pumps are intended for use in pipe and cassion jetting and field installation of well castings, as well as applications in environmental and pipeline work that require high flow and high pressure. Hand primers come standard, with automatic primers available as an option. Three-Stage Water Jet Pump From Griffin