Dissertation poster

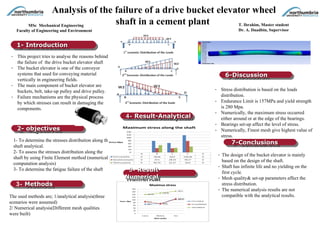

- 1. 4-4- Result-AnalyticalResult-Analytical4-4- Result-AnalyticalResult-Analytical 7-Conclusions7-Conclusions7-Conclusions7-Conclusions 6-Discussion6-Discussion6-Discussion6-Discussion 2- objectives2- objectives2- objectives2- objectives 3- MethodsMethods3- MethodsMethods 1- Introduction1- Introduction1- Introduction1- Introduction 1- To determine the stresses distribution along the shaft analytical. 2- To assess the stresses distribution along the shaft by using Finite Element method (numerical computation analysis) 3- To determine the fatigue failure of the shaft The used methods are; 1/analytical analysis(three scenarios were assumed) 2/ Numerical analysis(Different mesh qualities were built) 5-5- Result-Result- NumericalNumerical 5-5- Result-Result- NumericalNumerical - Stress distribution is based on the loads distribution. - Endurance Limit is 157MPa and yield strength is 280 Mpa. - Numerically, the maximum stress occurred either around or at the edge of the bearings. - Bearings set-up affect the level of stress. - Numerically, Finest mesh give highest value of stress. - The design of the bucket elevator is mainly based on the design of the shaft. - Shaft has infinite life and no yielding on the first cycle. - Mesh quality& set-up parameters affect the stress distribution. - The numerical analysis results are not compatible with the analytical results. Analysis of the failure of a drive bucket elevator wheel shaft in a cement plant - This project tries to analyse the reasons behind the failure of the drive bucket elevator shaft - The bucket elevator is one of the conveyor systems that used for conveying material vertically in engineering fields. - The main component of bucket elevator are buckets, belt, take-up pulley and drive pulley. - Failure mechanisms are the physical process by which stresses can result in damaging the components. a MSc Mechanical Engineering Faculty of Engineering and Environment T. Ibrahim, Master student Dr. A. Daadbin, Supervisor