Divider strips in terrazzo flooring

- 1. Divider Strips in Terrazzo Flooring

- 2. DESIGN LAYOUTS CONTROL CRACKING Terrazzo is often characterized by its aggregates and its binder (epoxy or cement). Divider strips play an important role in how terrazzo is installed, with several material and thickness options. Divider Strips are used in terrazzo floor for:

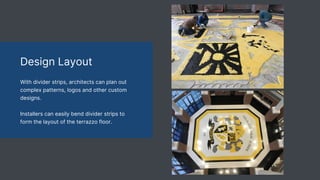

- 3. Design Layout With divider strips, architects can plan out complex patterns, logos and other custom designs. Installers can easily bend divider strips to form the layout of the terrazzo floor.

- 4. Color Transition Divider strips can also call for a color change in a terrazzo floor design. Installers will mix the appropriate colors and trowel the material between each section of divider strips.

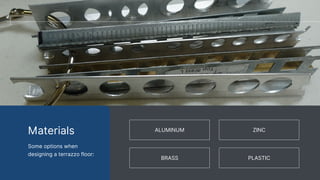

- 5. ALUMINUM BRASS ZINC PLASTIC Materials Some options when designing a terrazzo floor:

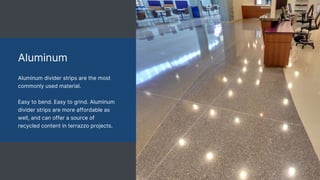

- 6. Aluminum Aluminum divider strips are the most commonly used material. Easy to bend. Easy to grind. Aluminum divider strips are more affordable as well, and can offer a source of recycled content in terrazzo projects.

- 7. Zinc Zinc divider strips are another option. Zinc divider strips look similar to aluminum, but have a higher price point.

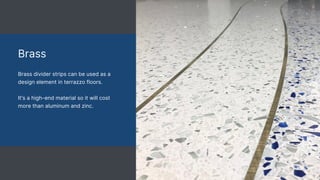

- 8. Brass Brass divider strips can be used as a design element in terrazzo floors. It's a high-end material so it will cost more than aluminum and zinc.

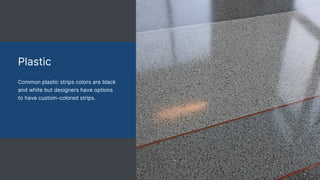

- 9. Plastic Common plastic strips colors are black and white but designers have options to have custom-colored strips.

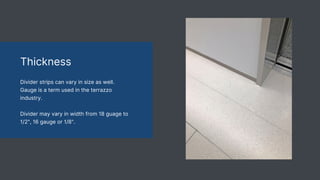

- 10. Thickness Divider strips can vary in size as well. Gauge is a term used in the terrazzo industry. Divider may vary in width from 18 guage to 1/2", 16 gauge or 1/8".

- 11. Control Cracking In helping the performance of terrazzo floors, divider strips control cracking in the terrazzo topping. Dividers should be placed precisely above any concrete joints.

- 12. Design Your Next Terrazzo Floor with TERRAZZCO Contact us at info@terrazzco.com