DPL Large scope nano-replication system -www.dpl.dk

- 1. Automatic Nanoimprint Replication System for Roll-to-Roll Nanofabrication process Authors of the presentation: Henrik Lindskov,Yan Xia (DPL Industri A/S Denmark)

- 2. What is Nanofabrication Process? NanofabricationNanosicents Semiconductor Laboratory Mass Production Printed Electronics SmartTV Smart Label Solar Energy

- 3. Why you need Nanostructure Replication System ? Nanostructure Replication System Nanostructure Master Roll-to-Roll Nanofabrication

- 4. Shim roller on Micro- Embosser for Holographic Film Shim roller

- 5. What is Nanostructure Mastering? RD E-BEAM MADE ds are provided on 20x20mm Si substrates. gh-resolution and large enough area of affordable price. These templates are normally hipment. 2 development growth structures ayers, photovoltaic patterning PRINT TEMPLATES ce Area Feature Diameter / Height Layout of the standard ebeam-made molds 5 mm 20 mm res Creating nanostructure on the object by Lithography System: E-beam, Laser, UVŌĆ”ŌĆ”.. and services nd laser interference orking stamps ng, Roll-2-Roll printing, and injection moulding bossing, EBL, DUV) typing, one-off devices, and small series

- 6. What is the problem in the market now? Visible Joints between the unit plates through microscope

- 7. How Does Nanoimprint Replication SystemWork?

- 8. DPL Automatic Replication System Die Head Workbench Integrated PLC Control system

- 9. What is DPL Know-how Die Head Die Head PDMS template Inside LED Light source Air chilling Automatic Pressure Control

- 10. How does it work? How Does ItWork?

- 11. OurObjectives: Replication line +/- 25mic Position accuracy +/- 25mic UV Nanoimprint Replication Sample Through Microscope

- 12. Feature 1: High-Solution Replication UV Imprint with polymer stamps (2:2) Master Working Stamp Substrate Optical Microscope 100x AFM ŌĆó Master depth is 514 nm, imprint depth is 503 nm. ŌĆó Perfect master to substrate replication

- 13. Feature 2: High Precision Positional Movement Position Error: +/- 0.025mm Position Error: +/- 0.025mm

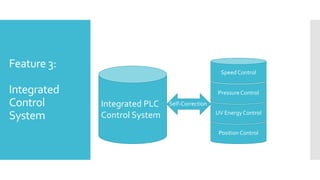

- 14. Feature 3: Integrated Control System Position Control Integrated PLC Control System UV Energy Control Pressure Control Speed Control Self-Correction

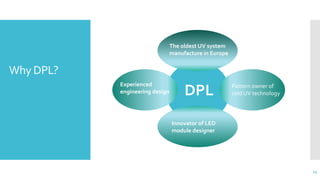

- 15. Why DPL? 15 Experienced engineering design The oldest UV system manufacture in Europe Pattern owner of cold UV technology Innovator of LED module designer DPL

- 16. OurActivities &Work Packages 16 PDMA Stamp LED Module Radiation and DOSIS testing Air-chilling system WP1: Die Head Design WP2:Workbench Design WP3:Integrated System Design Glass Plate Linear Motion System Porotype installation Position Control UV Energy Control Pressure Control Programing PLC UV EnergyTest ReplicationTest Nanoimprint Replication

- 17. 17 Director Technical Dept. Project Manager Marketing Dept. Leader of WP1,WP2,WP3 Regulatory risk assessment and testing Hold communication meeting Settlement of disputes etc. Business Plan Project Management

- 18. Marketing Strategy:We are not only searching potential demand but also creating new demand. 18 Marketing Workshop Optimization Production Cost Project Website Exhibition Conference

- 19. Product Strategy 19 Laboratory Mass Production Security Printing Optical Film DPL Current Sales Network

- 20. Competitive Analysis 20 Weakness Existing Products lose market in the face of competition from the low-priced products from the low labor area Strengths Opportunities Creativity & Innovative Experienced technical team High-quality control system Develop high-technology products for emerging industries with insufficient supply

- 21. Company Culture ’é¢Innovation is not just a dream of young people. 21 Thanks