DSM eBOOST, Industrially Proven Yeast Technology

- 1. CONFIDENTIAL Advanced Yeast Technologies ┬® 2020 DSM. All rights reserved. Same Corn, More Value: Industrially proven Yeast Technology Phil Bureman Sales Manager DSM Bio-Products & Services Phil.Bureman@DSM.com Cell: +1 913-708-4969 September 11, 2020

- 2. Page CONFIDENTIAL Confidential Phil BuremanŌĆō Sales Manager ŌĆó Started in biofuels industry in 1993 ŌĆó 25 yrs Technical Sales at Nalco with focus on process chemicals and fuel quality ŌĆó 10+yrs RFA Technical Committee ŌĆó Began with DSM in March 2020 Our Local Team ŌĆō DSM Biobased Product & Services Michael Mszal ŌĆō Bioprocess and Mfg Specialist ŌĆó Started in biofuels industry in 2014 ŌĆó 8 years experience in production, R&D, scale-up, and other roles in various fermentation houses as a supervisor and process development engineer ŌĆó Began with DSM in May 2016 1 Pat Moran ŌĆō Sales Manager ŌĆó Started in biofuels industry in 2005 ŌĆó Held various positions with Walling Water/ HOH Water, US Water including General Manager/President, Regional Sales Manager ŌĆó Began with DSM in August 2019 Who is DSM? Arvind Kaul ŌĆō Bioprocess and Mfg Specialist ŌĆó Started in biofuels industry in 2016 ŌĆó Held technical positions with Roche Vitamins, Novozymes, Genomatica, DSM ŌĆó Overall 25+ years of technical experience in fermentation based processes. ŌĆó Began with DSM in late May 2016

- 3. Page CONFIDENTIAL Confidential Our purpose is to create brighter lives for people today and generations to come We connect our unique competences in Life Sciences and Materials Sciences to create solutions that nourish, protect and improve performance DSM: A Global Innovation and Sustainability Leader ŌĆō #2 currently on Forbes Sustainability Index 2 Animal Nutrition & Health Human Nutrition & Health; Food Specialties; Personal Care Materials Sustainability Leader Fortune Magazine: 2nd in ŌĆ£Change the WorldŌĆØ index Intrinsically Innovative 21% sales from innovation products Global presence 22,174 employees worldwide Strong performance $10 billion sales up 2% from 2018 Other PEOPLE ŌĆō PLANET - PROFIT What can DSM offer to your site?

- 4. Page CONFIDENTIAL Confidential DSM in biofuels 150 years of yeast experience Vision: Accelerate the growth of biofuels as global fuel source Mission: Deliver the technologies and expertise that enhance biofuel production History: A rich history in ethanol production; began as Gist-Brocades producing yeast and spirits since 1869 150 years Gist-Brocades, NL Elgin, IL We are a relative new comer in USA Bioethanol so we must Innovate! Let me show you what we have created so far

- 5. Page CONFIDENTIAL Confidential Page 4 DSM technology in biofuels Ethanol industry - Corn process Pretreatment Enzymatic hydrolysis Fermentation Distillation Corn stover Ethanol Saccharification Fermentation Distillation Corn kernel Ethanol Corn mash Corn fiber Pretreatment & hydrolysis Fermentation DDGS Corn oil 1.5G EtOH 1G EtOH 2G EtOH Corn stover Project Liberty TodayŌĆÖs discussion will focus on our Yeast products, butŌĆ”. Adv. Yeast

- 6. Page CONFIDENTIAL Confidential Why Should You Consider DSM BP&S ŌĆó We are the newcomer to the USA Ethanol Industry ’ā╝ So we have to innovate and work harder to earn and keep your business! ’ā╝ DSM DOES NOT charge Technology or Ferm Fees ŌĆō All In $/kg Pricing! ŌĆó DSM Yeast produces a Cleaner Ethanol! ’ā╝ DSM Yeast delivers an average of 3% more ethanol compared to non GMO industry standard with the same or lower amounts of acetaldehyde & acetal & other fusels ’ā╝ Glycerol reduction (up to 68%) ’é¦ Lower energy costs by increasing drying and evaporator efficiency ’é¦ Improves whole stillage separation efficiency & corn oil recovery ’ā╝ We believe our nitrogen uptake pathway converts more carbon to useful amino acids & polypeptides thereby improving the quality of your DDGS ŌĆó We offer Monthly Lab Analysis, Quarterly Business Reviews & Regular Operator Training. We are MORE than a delivery & an invoice! 5

- 7. Page CONFIDENTIAL Confidential ŌĆó DSM Yeast has very good acid tolerances showing up to 0.5% LA + 0.2% AA with negligible inhibition to finish ’ā╝ DSM Yeast DO NOT contribute to the production of Acetic or Lactic acids ŌĆó eBoostTM GT offers high GA reductions (~50%) compared to traditional yeasts, and further increases shown over other GA expressing yeasts ’ā╝ A recent mini-ferm trial showed additional 25% GA reduction ŌĆó eBOOSTŌäó & eBOOSTŌäó GT are produced in the U.S. / All regulatory approvals in place (MCAN*, GRAS) ŌĆó At this time we offer only Active Dry Yeast (ADY) 6 I can share some Performance Data but first LetŌĆÖs talk about what is important to you *Microbial Commercial Activity Notices (MCANs) Why Should You Consider DSM BP&S

- 8. Page CONFIDENTIAL Confidential 7 LetŌĆÖs focus on your interest ŌĆó What is most important to you when choosing a yeast supplier? ŌĆó What are your expectations from a yeast supplier? ŌĆó What do you wish a yeast supplier would offer or innovate? ŌĆó Other thoughts/questions/coaching for us? ’ā╝ Are you making or considering making hand sanitizer? ŌĆó Do you have an ability to test our yeast in a mini ferm or lab trial? ’ā╝ If so, do you place much value is such tests? ŌĆó Is there an appetite now to trial one or both of our yeast? ’ā╝ Have you had challenges optimizing your plant to a new yeast in the past? ’ā╝ If so, what expectations do you have for DSM in a potential trial or switch? ’ā╝ We are offering very low cost trials at this time!

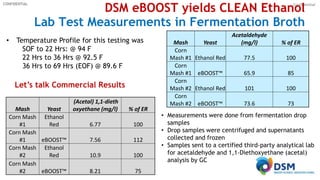

- 9. Page CONFIDENTIAL Confidential DSM eBOOST yields CLEAN Ethanol Lab Test Measurements in Fermentation Broth 8 Mash Yeast Acetaldehyde (mg/l) % of ER Corn Mash #1 Ethanol Red 77.5 100 Corn Mash #1 eBOOSTŌäó 65.9 85 Corn Mash #2 Ethanol Red 101 100 Corn Mash #2 eBOOSTŌäó 73.6 73 Mash Yeast (Acetal) 1,1-dieth oxyethane (mg/l) % of ER Corn Mash #1 Ethanol Red 6.77 100 Corn Mash #1 eBOOSTŌäó 7.56 112 Corn Mash #2 Ethanol Red 10.9 100 Corn Mash #2 eBOOSTŌäó 8.21 75 ŌĆó Temperature Profile for this testing was SOF to 22 Hrs: @ 94 F 22 Hrs to 36 Hrs @ 92.5 F 36 Hrs to 69 Hrs (EOF) @ 89.6 F ŌĆó Measurements were done from fermentation drop samples ŌĆó Drop samples were centrifuged and supernatants collected and frozen ŌĆó Samples sent to a certified third-party analytical lab for acetaldehyde and 1,1-Diethoxyethane (acetal) analysis by GC LetŌĆÖs talk Commercial Results

- 10. Page CONFIDENTIAL Confidential Commercial trial results with Same corn, more value eBOOSTŌäó compared to market standard: ŌĆó About 3% avgerage EtOH yield improvement ŌĆó Down to 68% glycerol reduction 32% 45% 38% 50% 40% 41% 38% 41% 0% 20% 40% 60% 80% 100% Market standard Plant 1 Plant 2 Plant 3 Plant 4 Plant 5 Plant 6 Plant 7 Average Low glycerol levels eBOOSTŌäó 2.0% 5.0% 4.7% 3.5% 2.1% 1.9% 2.5% 3.1% 98% 100% 102% 104% 106% Market standard Plant 1 Plant 2 Plant 3 Plant 4 Plant 5 Plant 6 Plant 7 Average EtOH yield improvement eBOOSTŌäó Equal or very similar performance observed with eBOOSTŌäó GT In todayŌĆÖs low price market your plant could make the same ethanol with less corn input cost! How does DSM compare with other Market Leaders?

- 11. Page CONFIDENTIAL Confidential Page 10 Outperforms competitors Best yield potential in the market 2.5 - 5% 50 - 60% Equal or very similar performance observed with eBOOSTŌäó GT Let me share details on in Plant Performance Data for eBoost GT Vs a Competitor Advanced Yeast

- 12. Page CONFIDENTIAL Confidential Charts at Fermentation drop ŌĆō Trial-O-Rama eBOOSTŌäó delivers higher EtOH and EtOH/Liq solids at drop 11 ┬® 2019 DSM. All rights reserved. ’āśeBOOSTŌäó delivers consistently higher EtOH titers and yields at drop vs. the other two strains. Compt 1 - Baseline Compt 2 eBOOSTŌäó Compt 2 eBOOSTŌäó Ethanol Ethanol/Liq solids Compt 1 ŌĆō Re-baseline Compt 1 - Baseline Compt 1 ŌĆō Re-baseline

- 13. Page CONFIDENTIAL Confidential eBOOSTŌäó GT Recipe ŌĆō Key Operating Conditions 12 ŌĆó Propagator ŌĆō Liq solids ~ 20%; Yeast Pitch ŌĆō 1 g/l with opportunity for optimization. ŌĆō Urea ~ 1 g/l ŌĆō No GA ŌĆō Propagation time of ~ 8-9 hrs ŌĆō Temperature: 90-93 F ŌĆó Main Fermenter ŌĆō Mash solids of 32-34% ŌĆō Urea ~1.0- 0.8 g/l ŌĆō 50% of normal GA dosage ŌĆō Plant standard temperature staging 92 ŌĆō 88 F targeted ranges; ŌĆō In sustained commercial use, eBOOST GT had good finish with high ethanol titers even when fermentation temperatures occasionally peaked at 95F First, let me share some sugar consumption data vs a competitor using this recipe

- 14. Page CONFIDENTIAL Confidential 13 eBOOST GT vs. Comp Yeast - Sugar Profiles @ Recent Ferm Trial Equal or very similar performance observed with eBOOSTŌäó

- 15. Page CONFIDENTIAL Confidential 14 Evaluation of performance ŌĆō eBOOST GT vs. Comp Yeast @ Recent Ferm Trial ŌĆó This data is @ a 50% reduction in GA which can be optimized up to 70%. ŌĆó eBOOST GT has a higher tolerance for glucose peak compared to competitor yeast ŌĆó eBOOSTŌäó GT produces less Glycerol during fermentation ŌĆó No significant difference in lactic and acetic acid production compared to current plant levels. Equal or very similar performance observed with eBOOSTŌäó

Editor's Notes

- #4: Biofuels included in