Dynocast CFF Zirconia Catalogue

- 1. MANUFACTURERS OF QUALITY CERAMICMANUFACTURERS OF QUALITY CERAMICMANUFACTURERS OF QUALITY CERAMICMANUFACTURERS OF QUALITY CERAMIC FOAM FILTERSFOAM FILTERSFOAM FILTERSFOAM FILTERS

- 2. Products DYNOCAST is the only Indian Company at present to manufacture the Ceramic foam filters in the country. We have indigenously developed the technology to make various types of ceramic foam filters. Our variety includes: 1 .Zirconia Foam Filters for Plain Carbon Steel , Alloy Steels and DYNOCAST We have indigenously developed the technology to make various types of ceramic foam filters. Our variety includes: 1 .Zirconia Foam Filters for Plain Carbon Steel , Alloy Steels and Stainless Steel Castings 2. Silicon Carbide Foam Filters for Ductile and Cast Iron 3. Alumina Foam Filters for Aluminum filtration 4. Zircon Foam Filters for Heavy CI and Ductile Iron Castings

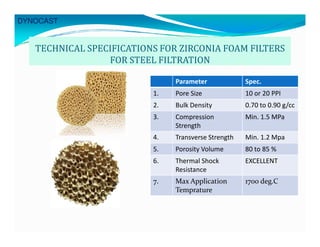

- 3. TECHNICAL SPECIFICATIONS FOR ZIRCONIA FOAM FILTERS FOR STEEL FILTRATION Parameter Spec. 1. Pore Size 10 or 20 PPI 2. Bulk Density 0.70 to 0.90 g/cc 3. Compression Strength Min. 1.5 MPa DYNOCAST Strength 4. Transverse Strength Min. 1.2 Mpa 5. Porosity Volume 80 to 85 % 6. Thermal Shock Resistance EXCELLENT 7. Max Application Temprature 1700 deg.C

- 4. WHY USE DYNOCAST FOAM FILTERS ? Sr. no. Characteristics Benefits 1. Very high surface area Filtration efficiency is increased 2. Filter material is wetting to slags and non metallic Inclusions and is non wetting to metals. Micro inclusions are also trapped irrespective of pore size of the filter. 3. High mechanical strength at room temp. Safe and easy handling. DYNOCAST temp. 4. High service temp. strength Filter does not break or sag during service 5. Expertise in casting technology Expertise in foundry technology enables to provide customized solutions to your Filtration problems 6. High Thermal Shock Resistance Filter does not break when it comes in sudden contact with high temp. liquid metal. 7. Rigorous QC/Inspection Process Ensures high and consistent quality.

- 5. Major Advantages of Using Foam FiltersMajor Advantages of Using Foam FiltersMajor Advantages of Using Foam FiltersMajor Advantages of Using Foam Filters • Reduced rejection rates and hence reduced cost of production. • High Filtration efficiency ensures min. level of inclusions. • Reduction in turbulence in metal flow prevents re oxidation of the metal after filtration. • Filter does not act as choke in the system as is the case with ceramic strainers. • Both cake and depth filtration is achieved. • Filter does not chemically react with most of the metals and alloys. • Savings in terms of metal, energy etc. by way of reducing rejection DYNOCAST metal after filtration. • Filter does not act as choke in the system as is the case with ceramic strainers. • Both cake and depth filtration is achieved. • Filter does not chemically react with most of the metals and alloys. • Savings in terms of metal, energy etc. by way of reducing rejection rates, increasing yield, reducing machining allowances, increasing tool life. • Enhancement in mechanical properties like tensile strength, elongation and impact strength of castings is achieved. • Improved machinability of castings. • Improved yield of castings as no complicated running systems are required to trap the slag and non metallic particles.

- 6. CONTACT DYNOCAST Plot # J-66, M.I.D.C., Kupwad, City: Sangli. PIN: 416436 State: maharashtra Country: indiaCountry: india Mobile : +919890647275 +918554025353 Mr. Satish Sahasrabudhe B.E.(Metallurgy) Email: dynocast@gmail.com sales@dynocastindia.com