Effct of Tungsten Inert Gas Welding & Shielded Metal Arc Welding Processes on Mechanical Properties of Super Duplex Stainless Steel (AISI 2507)

- 2. STUDENTS ARJUN M 2010118004 MOHAN RAJ N 2010118030 SURYAPRAKASH S 2010118050 RAJESH R 2010118058 GUIDE Dr. K. SHANMUGA SUNDARAM ASSOCIATE PROFESSOR DEPARTMENT OF MECHANICAL ENGINEERING COLLEGE OF ENGINEERING,GUINDY, ANNA UNIVERSITY CHENNAI 600025 CO-GUIDE Mr. A.VINOTH JEBARAJ TEACHING RESEARCHASSITANT DEPARTMENTOF MECHANICAL ENGINEERING COLLEGE OF ENGINEERING,GUINDY, ANNA UNIVERSITY CHENNAI 600025

- 6. Etchant used: Aquaregia (Hydrochloric acid + Sulphuric acid) Standard: IS. 7739 (PartV) 1976 Magnification: 100x

- 7. Carbon 0.0280 % 0.030 % max Copper 0.2700 % 0.500 % max Chromium 24.0200 % 24 % - 26 % Manganese 1.1000 % 1.20 % max Molybdenum 3.1700 % 3 % - 5 % Nickel 6.5000 % 6 % - 8 % Phosphorous 0.0150 % 0.035 % max Sulphur 0.0150 % 0.020 % max Silicon 0.2950 % 0.800 % max

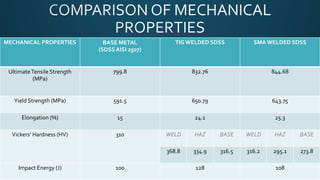

- 15. MECHANICAL PROPERTIES BASE METAL (SDSS AISI 2507) TIG WELDED SDSS SMA WELDED SDSS UltimateTensile Strength (MPa) 799.8 832.76 844.68 Yield Strength (MPa) 591.5 650.79 643.75 Elongation (%) 15 24.1 25.3 VickersŌĆÖ Hardness (HV) 310 WELD HAZ BASE WELD HAZ BASE 368.8 334.9 316.5 316.2 295.1 273.8 Impact Energy (J) 100 128 108

- 16. SPECIMEN 1 SPECIMEN 2

- 17. SPECIMEN 1 SPECIMEN 2

- 18. WELD ZONE: The microstructure shows acicular ferrite and austenite grains.The percentage of ’üĪ and ’ü¦ is 68% ’ü½ 32% HAZ: The microstructure shows coarser acicular ferrite and austenite grains.The percentage of ’üĪ and ’ü¦ is 65% ’ü½ 35% BASE: The microstructure shows elongated ferrite-austenite grains.The percentage of ’üĪ and ’ü¦ is 62% ’ü½ 38%

- 19. WELD ZONE: The microstructure shows acicular ferrite and austenite grains.The percentage of ’üĪ and ’ü¦ is 71% ’ü½ 29% HAZ: The microstructure shows coarser acicular ferrite and austenite grains.The percentage of ’üĪ and ’ü¦ is 67% ’ü½ 33% BASE: The microstructure shows elongated ferrite-austenite grains.The percentage of ’üĪ and ’ü¦ is 61% ’ü½ 39%