EFPCB Provide the Best Rigid Flexible PCB Manufacturer.pptx

- 2. Know About the Key Properties of Ceramic PCB Ceramic PCB, also known as ceramic substrates or alumina PCBs, are a specialized type of printed circuit board that employs ceramic materials as the base substrate. Unlike conventional PCBs that use epoxy-based materials, ceramic PCBs utilize ceramics like alumina (aluminum oxide) or aluminum nitride. The choice of ceramic material depends on the specific requirements of the application. Read our full blog

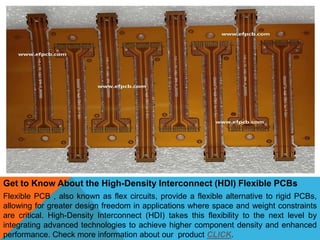

- 3. Get to Know About the High-Density Interconnect (HDI) Flexible PCBs Flexible PCB , also known as flex circuits, provide a flexible alternative to rigid PCBs, allowing for greater design freedom in applications where space and weight constraints are critical. High-Density Interconnect (HDI) takes this flexibility to the next level by integrating advanced technologies to achieve higher component density and enhanced performance. Check more information about our product CLICK.

- 4. Layer Stackup in High-Speed PCB Design Offers More Performance PCB layer stackup refers to the arrangement and configuration of copper and insulating layers in a printed circuit board. While it may appear to be a straightforward aspect of design, the layer stackup significantly influences the electrical performance and reliability of a High Speed PCB . Proper layer stackup is essential for mitigating signal integrity issues, managing power distribution, and ensuring thermal stability. Know more CLICK.

- 5. The Ceramic Substrates is A Technological Marvel in PCBs A PCB's substrate is the material on which the circuit components are mounted and interconnected. Traditionally, fiberglass-reinforced epoxy resin (FR-4) has been the go-to choice for PCB substrates due to its cost-effectiveness and ease of manufacturing. However, as electronic devices become more sophisticated, the limitations of FR-4 in terms of thermal performance and reliability have become apparent. Get more CLICK.