Eig ati 1b

Download as pptx, pdf0 likes332 views

This document describes Activated Clay, a modified clay product manufactured by Aqua Technologies Inc. that is highly effective at removing hydrocarbons and other organic pollutants from water. It adsorbs 50-140% of its weight in pollutants, far more than granular activated carbon. Activated Clay is used in water treatment systems for applications like produced water filtration and soil remediation. It has been used successfully in thousands of installations to clean water to levels suitable for discharge or drinking.

1 of 11

Download to read offline

Ad

Recommended

ETP

ETP Jotish Roy (BUBT)

╠²

This document provides an overview of the effluent treatment process at Delta Knit Composite Ltd. It describes the various stages of ETP including screening, equalization, pH correction, aeration, sedimentation, sludge thickening, and effluent discharge. The key stages involve using bacteria to biologically treat 120 m3/hr of wastewater over 8 hours in an aeration tank, sedimentation to separate solids from treated water, and sludge thickening before partial recycled is returned to the aeration tank and the remainder is discharged. The multi-stage biological and physical separation process aims to treat industrial wastewater before discharge.ETP Phase-II

ETP Phase-IIFahad Khan(tomeetfahad@gmail.com)

╠²

This document describes upgrades to Attock Refinery Ltd.'s effluent treatment plant (ETP) to enhance its capacity and comply with environmental regulations. The upgrades include:

1) Adding secondary treatment with an activated sludge system and clarifier after primary treatment via dissolved air flotation.

2) Upgrading API separators with scrapers to remove solids, oil skimmers to remove oil, and oil coalescers.

3) Expanding effluent treatment capacity from 100 to 200 gallons per minute and adding biological secondary treatment to remove more contaminants like BOD, COD, and oil/grease.Leachate Treatment Ad Plant Technical Bulletin

Leachate Treatment Ad Plant Technical BulletinEKO GEA

╠²

This document summarizes an EKO GEA biological leachate treatment plant that provides a simple and economical on-site solution to treating landfill leachate. The system uses anaerobic digestion and novel filtration and ion exchange technologies to reduce COD, BOD, TSS, phosphorus, nitrates and produce effluent that meets EU standards without additional wastewater treatment. It lowers treatment costs by eliminating transportation and fees to wastewater plants while using no power and producing no odors.Environmental regulations 2009

Environmental regulations 2009ainurasyikinNur

╠²

These regulations establish standards and requirements for industrial effluent discharge in Malaysia. They require industries that discharge effluent to:

1. Notify authorities of new or changed discharge sources and treat effluent according to approved standards.

2. Monitor effluent quality and quantity, maintain records, and submit monitoring reports.

3. Operate and maintain effluent treatment systems properly using competent supervisors, and conduct performance monitoring according to guidelines.

The regulations specify effluent quality standards, record keeping and personnel training requirements to control pollution from industrial sources.WASTE WATER TREATMENT REFINERIES

WASTE WATER TREATMENT REFINERIES Arun Sarasan

╠²

The document discusses the significant environmental impact of wastewater generated by petroleum refineries, which produce various pollutants during oil processing. It outlines the types of wastes, wastewater treatment processes, and the importance of compliance with environmental regulations, emphasizing the necessity for effective waste management and pollution reduction strategies. The document also highlights the challenges of treating contaminated water due to the complex chemical properties of oil and the diverse nature of industrial waste.Zero liquid discharge

Zero liquid dischargeTulsi Makwana

╠²

The document provides an overview of zero liquid discharge (ZLD) technologies. It discusses:

1) ZLD refers to recycling and treating wastewater such that no liquid is discharged, eliminating pollution. It involves concentrating effluent and converting solutes to solid residue.

2) Key ZLD technologies include solvent extraction, membrane bioreactors, ultrafiltration/reverse osmosis, evaporation like falling film evaporators, and agitated thin film dryers.

3) Challenges include a lack of technical guidance, complex wastewater streams, and needing integrated technologies for reduce, recycle, recovery and reuse.Etp plant

Etp plant DineshMore29

╠²

The document describes the key components and processes of an effluent treatment plant (ETP). The ETP treats industrial wastewater in multiple stages including preliminary treatment to remove solids, primary treatment using sedimentation, secondary treatment using biological processes like activated sludge, and tertiary/advanced treatment using techniques like sand filters to further polish the water before discharge or reuse. The ETP aims to clean industrial effluent to reduce freshwater usage and allow safe release of water back into the environment while meeting pollution standards.Waste Water Treatment plant

Waste Water Treatment plant wesme1234

╠²

This document describes a compact wastewater treatment system using MBR/MBBR technology. It provides excellent quality treated sewage using minimal space. The system combines fixed film and activated sludge processes for high treatment efficiency and stability. It allows for water recycling and reuse while saving water, energy, and protecting the environment. The system is designed for small footprints and low operation and maintenance costs.Zero liquid discharge

Zero liquid dischargeUmangi Mehta

╠²

This document discusses zero liquid discharge (ZLD) systems. It provides background on the need for ZLD due to water scarcity issues. It then describes the key steps in a ZLD process, which involves pre-treatment, evaporation, and crystallization to separate water for reuse from solids for disposal. Common technologies used are reverse osmosis, mechanical vapor recompression, and multiple effect evaporators. The document concludes with two case studies of industries that have implemented ZLD systems successfully.Common effluent treatment plant

Common effluent treatment plantnirmalk1503

╠²

This document describes a common effluent treatment plant (CETP) designed to treat wastewater from tanneries. It first provides background on tanneries and the wastewater generation process. It then outlines the key components of the CETP, including primary treatment using screens and settling tanks, secondary treatment using aeration and clarification, and tertiary treatment using filters. It also discusses chemical dosing requirements and design parameters like retention time. The CETP is presented as an effective way to treat combined wastewater from multiple tanneries to reduce costs and help meet discharge standards.INTRO OF RWT

INTRO OF RWTSuvamoy Dutta

╠²

RWT India Pvt. Ltd. is a manufacturer, supplier, and exporter of various water purification products based in Ahmedabad, India. These include RO plants, effluent treatment plants, sewage treatment plants, DM plants, ultrafiltration plants, water softening plants, and more. The company provides information on its directors and contacts for different divisions. It also describes the features and technologies used for its various plant offerings and supplies various water treatment chemicals and spare parts.ETP- Effluent Treatment Plant

ETP- Effluent Treatment PlantMd. Mazadul Hasan Shishir

╠²

This document describes the effluent treatment plant (ETP) of Delta Knit Composite Ltd. The ETP uses a biological treatment process to treat 120 m3/hr of industrial wastewater. The treatment process includes screening, equalization, pH correction, aeration, sedimentation, sludge thickening, and recycling of sludge. The ETP is able to reduce pollutants in the wastewater and produce treated effluent that can be safely discharged and dried sludge.Oil & Gas industry Waste Management

Oil & Gas industry Waste Managementmamdouh sabour

╠²

The document discusses waste management in the oil and gas industry. It identifies several types of waste generated including tank bottom sludge, spill cleanup materials, municipal solid waste, and hazardous waste. It provides objectives to identify challenges in sustainable waste management and compare factors affecting waste management in developed versus less developed oil areas. The document then discusses various waste management strategies like reduction, reuse, recycling, and treatment and applies them to specific waste streams from oil and gas facilities.Integrated green technologies for msw (mam ver.)

Integrated green technologies for msw (mam ver.)mamdouh sabour

╠²

Saudi Arabia faces significant challenges in municipal solid waste (MSW) management due to rapid demographic and industrial growth, with a need for cost-effective, sustainable solutions. Key strategies include improving recycling, energy recovery, and implementing innovative technologies such as transfer stations and gasification to manage waste efficiently while reducing its environmental impact. The document emphasizes the importance of private sector involvement and advanced technologies for achieving effective waste management and minimizing greenhouse gas emissions.L 10 neutralization

L 10 neutralizationDr. shrikant jahagirdar

╠²

The document discusses industrial waste neutralization. It defines neutralization as treating industrial waste so it is neither too acidic nor too alkaline for safe discharge. Some reasons for neutralizing waste include making it compatible with municipal sewage systems and preventing corrosion. Common neutralization methods include mixing acidic and alkaline wastes, passing acid waste through limestone beds, and adding alkaline substances like lime, caustic soda, or sulfuric acid to acidic or alkaline waste depending on the pH. Proper sizing of neutralization tanks and retention times are also discussed.Zero Liquid Discharge Technology - UPL

Zero Liquid Discharge Technology - UPLprachishinde01

╠²

Zero liquid discharge (ZLD) is a wastewater management technique that eliminates liquid waste discharge, but it is not universally suitable due to its high carbon emissions, significant solid waste generation, and costly operational requirements. A comparative techno-economic feasibility study for a 2.5 MLD effluent treatment plant reveals that ZLD leads to higher power consumption, CO2 emissions, and waste generation compared to standard discharge norms. The document concludes that ZLD is not environmentally friendly, particularly in coastal areas, and should only be adopted when absolutely necessary.Etp Final Report

Etp Final ReportNishith Tripathi

╠²

This document provides details on the design and process of an effluent treatment plant (ETP) at Rourkela Steel Plant. The ETP uses coagulants, flocculants and pH adjusters to treat wastewater from the gas cleaning plant. Key components of the ETP include flash mixers for chemical treatment, thickeners to separate solids from water, sludge tanks for sludge storage, and a filter press to dewater the sludge. The ETP is designed to meet performance standards for treated water quality and sludge moisture content.Report on Effluent Treatment Plant (ETP) Operation and Maintenance of Interst...

Report on Effluent Treatment Plant (ETP) Operation and Maintenance of Interst...Kowshick Sen

╠²

The report outlines the operation and maintenance of the effluent treatment plant (ETP) at Interstoff Apparels Ltd (IAL) in Bangladesh, detailing its capacity, treatment process, and compliance with environmental standards. IAL, known for its advanced garment manufacturing, has implemented a biological ETP system capable of treating wastewater generated from its processes before discharge. Key challenges include instrument shortages and the need for improvements in sludge handling and treatment efficiency.Zero Liquid Discharge Plant

Zero Liquid Discharge Plant Kelvin Water Technologies Pvt Ltd

╠²

Kelvin Water Technologies Pvt Ltd offers zero liquid discharge (ZLD) solutions for efficient wastewater management, enabling recovery of over 95% of wastewater and compliance with stringent discharge regulations. A typical ZLD treatment system includes components such as clarifiers, chemical feeds, ultrafiltration, reverse osmosis, and crystallizers tailored to specific contaminants and flow rates. These technologies help recover valuable products from wastewater and improve water quality for reuse in various industrial applications.Presentation on ETP (Effluent Treatment Plant)

Presentation on ETP (Effluent Treatment Plant) Amanuzzaman Aman

╠²

The document discusses the treatment of industrial wastewater in an effluent treatment plant (ETP). It describes the various treatment units used in an ETP including preliminary (screens, grit chambers), primary (sedimentation tanks), secondary (activated sludge process, trickling filters), and tertiary (filtration, activated carbon) treatments. The goal of an ETP is to remove pollutants from wastewater through physical, chemical, and biological processes before discharge or reuse, in order to prevent environmental pollution and protect public health. Major pollutants removed include suspended solids, oil and grease, and organic materials that consume oxygen.Ankit Alankar ETP

Ankit Alankar ETPAnkit Alankar

╠²

This document presents information on an effluent treatment plant (ETP) including the treatment scheme and process. The ETP treats 1500 m3/day of wastewater generated from a company to reduce COD and BOD levels and meet standards for discharge. The treatment process includes screens, equalization tanks, anaerobic hybrid reactors, aeration tanks, lamella clarifier tanks, and final tanks. The ETP aims to reduce pollutants and allow treated water to be safely discharged or reused.Effluent Treatment Plant-Project-02

Effluent Treatment Plant-Project-02Nilusha Rajashilpa

╠²

The document reports on a project to analyze the efficiency, loading capacity, problems, and potential improvements of an effluent treatment plant at Workwear Lanka.

Key findings include:

1. The plant maintains over 90% efficiency in reducing COD levels in effluent. Daily monitoring is needed to maintain efficiency.

2. The equalization tank's loading capacity is 50,000L and helps homogenize waste streams.

3. Common problems include pH variations, froth, and bacterial growth issues. Solutions include improving aeration, dosing, and hydraulic retention times.

4. Potential upgrades include recycling water through tanks multiple times, new flow configurations to improve bacterial activity, and advanced technologies likeZLD fundamentals&design-Lenntech BV

ZLD fundamentals&design-Lenntech BVChristos Charisiadis

╠²

This document serves as a comprehensive guide to the fundamentals and design of zero liquid discharge (ZLD) systems, focusing on brine treatment technologies. It covers various chapters that detail brine properties, conventional treatment methods, ZLD design principles, and brine recovery options with an emphasis on sustainability and cost efficiency. The guide also aims to assist industries in effectively managing brine waste amid increasing regulatory pressures and environmental considerations.Waste Water Treatment Plant

Waste Water Treatment PlantKeshav

╠²

This document summarizes a case study on the Common Effluent Treatment Plant (CETP) in Solapur, India. The CETP treats 3 million liters per day of wastewater from textile industries in Solapur. The treatment process includes preliminary, primary, secondary, and tertiary treatments to reduce parameters like BOD, COD, TSS, oil and grease. After treatment, BOD is reduced by 80% and COD by 95%. However, more treatment is needed to reduce chloride levels in the effluent. The CETP provides effective wastewater treatment for textile industries while reducing individual treatment costs.Effluent treatment plants

Effluent treatment plantsNikhil Kumar

╠²

The document discusses common effluent treatment plants (CETPs), which treat wastewater from multiple industrial plants before disposal or reuse. CETPs allow for economies of scale in wastewater treatment. They address issues like lack of space and provide more consistent treatment than individual plants. However, operating a CETP that receives varied wastewater can be challenging. The document outlines several factors that influence CETP planning and operation, as well as different wastewater treatment technologies, advantages of CETPs, challenges, categories of industries served, effluent treatment steps, conveyance methods, disposal methods, and treated effluent quality standards.common effluent treatment plant

common effluent treatment plantkrishnanand kushwaha

╠²

The document summarizes the operations of a Common Effluent Treatment Plant (CETP) in Baddi, India. The CETP treats 25 million liters of industrial wastewater per day that is collected from over 300 industries through a 62km pipeline network. It categorizes the wastewater into 5 categories based on contamination levels and treats it using various tanks, instruments, and processes like bioaugmentation and chemical preparation. Key operations include equalization, sedimentation, aeration, and tertiary treatment. The CETP aims to reduce environmental pollution through centralized treatment of industrial effluent.ZLD.ppt-Aquatech. Delhi 2015

ZLD.ppt-Aquatech. Delhi 2015satish bhatt

╠²

Zero liquid discharge (ZLD) refers to systems that enable absolute recycling of treated wastewater and conversion of dissolved solids into solid residue through concentration and thermal evaporation. ZLD certification is based on water consumption, wastewater recycled, and solids recovered. Conventional ZLD uses multi-effect evaporation, but this requires high steam consumption. A new technology called polymeric film evaporation uses polymer films as the heat transfer surface, achieving lower operating costs than multi-effect evaporation through reduced steam and power usage. This polymeric film evaporation technology provides benefits like low maintenance and scaling resistance.Membrane process for water treatment

Membrane process for water treatmentMdRomzanAli1

╠²

Microfiltration is an inexpensive water treatment process that uses membranes to reduce turbidity, suspended substances, and bacteria. It has advantages like reducing treatment chemicals and microorganisms while lowering costs compared to conventional treatment. However, it may require pretreatment to prevent fouling and scaling, and membranes require replacement every 3-5 years. Microfiltration is used for water pre-treatment in various biological and membrane processes. Ultrafiltration and nanofiltration can remove even smaller particles and molecules but not salts or sugars. Reverse osmosis uses pressure to force purified water through a semi-permeable membrane, leaving behind dissolved ions and larger particles.ETP Process Pearl Water Technologies.pptx

ETP Process Pearl Water Technologies.pptxPearl Water Technologies

╠²

Pearl Water Technologies specializes in designing effluent treatment plants (ETPs) for industrial wastewater management, utilizing techniques such as evaporation, centrifuging, filtration, and incineration to ensure safe disposal or reuse. The ETP process involves multiple stages including screening, coagulation, sedimentation, filtration, and disinfection to purify water before distribution. The company offers a range of semi-automatic ETP systems tailored for different industrial needs, aiming to meet regulatory zero-discharge measures and enhance water recycling efficiency.More Related Content

What's hot (20)

Zero liquid discharge

Zero liquid dischargeUmangi Mehta

╠²

This document discusses zero liquid discharge (ZLD) systems. It provides background on the need for ZLD due to water scarcity issues. It then describes the key steps in a ZLD process, which involves pre-treatment, evaporation, and crystallization to separate water for reuse from solids for disposal. Common technologies used are reverse osmosis, mechanical vapor recompression, and multiple effect evaporators. The document concludes with two case studies of industries that have implemented ZLD systems successfully.Common effluent treatment plant

Common effluent treatment plantnirmalk1503

╠²

This document describes a common effluent treatment plant (CETP) designed to treat wastewater from tanneries. It first provides background on tanneries and the wastewater generation process. It then outlines the key components of the CETP, including primary treatment using screens and settling tanks, secondary treatment using aeration and clarification, and tertiary treatment using filters. It also discusses chemical dosing requirements and design parameters like retention time. The CETP is presented as an effective way to treat combined wastewater from multiple tanneries to reduce costs and help meet discharge standards.INTRO OF RWT

INTRO OF RWTSuvamoy Dutta

╠²

RWT India Pvt. Ltd. is a manufacturer, supplier, and exporter of various water purification products based in Ahmedabad, India. These include RO plants, effluent treatment plants, sewage treatment plants, DM plants, ultrafiltration plants, water softening plants, and more. The company provides information on its directors and contacts for different divisions. It also describes the features and technologies used for its various plant offerings and supplies various water treatment chemicals and spare parts.ETP- Effluent Treatment Plant

ETP- Effluent Treatment PlantMd. Mazadul Hasan Shishir

╠²

This document describes the effluent treatment plant (ETP) of Delta Knit Composite Ltd. The ETP uses a biological treatment process to treat 120 m3/hr of industrial wastewater. The treatment process includes screening, equalization, pH correction, aeration, sedimentation, sludge thickening, and recycling of sludge. The ETP is able to reduce pollutants in the wastewater and produce treated effluent that can be safely discharged and dried sludge.Oil & Gas industry Waste Management

Oil & Gas industry Waste Managementmamdouh sabour

╠²

The document discusses waste management in the oil and gas industry. It identifies several types of waste generated including tank bottom sludge, spill cleanup materials, municipal solid waste, and hazardous waste. It provides objectives to identify challenges in sustainable waste management and compare factors affecting waste management in developed versus less developed oil areas. The document then discusses various waste management strategies like reduction, reuse, recycling, and treatment and applies them to specific waste streams from oil and gas facilities.Integrated green technologies for msw (mam ver.)

Integrated green technologies for msw (mam ver.)mamdouh sabour

╠²

Saudi Arabia faces significant challenges in municipal solid waste (MSW) management due to rapid demographic and industrial growth, with a need for cost-effective, sustainable solutions. Key strategies include improving recycling, energy recovery, and implementing innovative technologies such as transfer stations and gasification to manage waste efficiently while reducing its environmental impact. The document emphasizes the importance of private sector involvement and advanced technologies for achieving effective waste management and minimizing greenhouse gas emissions.L 10 neutralization

L 10 neutralizationDr. shrikant jahagirdar

╠²

The document discusses industrial waste neutralization. It defines neutralization as treating industrial waste so it is neither too acidic nor too alkaline for safe discharge. Some reasons for neutralizing waste include making it compatible with municipal sewage systems and preventing corrosion. Common neutralization methods include mixing acidic and alkaline wastes, passing acid waste through limestone beds, and adding alkaline substances like lime, caustic soda, or sulfuric acid to acidic or alkaline waste depending on the pH. Proper sizing of neutralization tanks and retention times are also discussed.Zero Liquid Discharge Technology - UPL

Zero Liquid Discharge Technology - UPLprachishinde01

╠²

Zero liquid discharge (ZLD) is a wastewater management technique that eliminates liquid waste discharge, but it is not universally suitable due to its high carbon emissions, significant solid waste generation, and costly operational requirements. A comparative techno-economic feasibility study for a 2.5 MLD effluent treatment plant reveals that ZLD leads to higher power consumption, CO2 emissions, and waste generation compared to standard discharge norms. The document concludes that ZLD is not environmentally friendly, particularly in coastal areas, and should only be adopted when absolutely necessary.Etp Final Report

Etp Final ReportNishith Tripathi

╠²

This document provides details on the design and process of an effluent treatment plant (ETP) at Rourkela Steel Plant. The ETP uses coagulants, flocculants and pH adjusters to treat wastewater from the gas cleaning plant. Key components of the ETP include flash mixers for chemical treatment, thickeners to separate solids from water, sludge tanks for sludge storage, and a filter press to dewater the sludge. The ETP is designed to meet performance standards for treated water quality and sludge moisture content.Report on Effluent Treatment Plant (ETP) Operation and Maintenance of Interst...

Report on Effluent Treatment Plant (ETP) Operation and Maintenance of Interst...Kowshick Sen

╠²

The report outlines the operation and maintenance of the effluent treatment plant (ETP) at Interstoff Apparels Ltd (IAL) in Bangladesh, detailing its capacity, treatment process, and compliance with environmental standards. IAL, known for its advanced garment manufacturing, has implemented a biological ETP system capable of treating wastewater generated from its processes before discharge. Key challenges include instrument shortages and the need for improvements in sludge handling and treatment efficiency.Zero Liquid Discharge Plant

Zero Liquid Discharge Plant Kelvin Water Technologies Pvt Ltd

╠²

Kelvin Water Technologies Pvt Ltd offers zero liquid discharge (ZLD) solutions for efficient wastewater management, enabling recovery of over 95% of wastewater and compliance with stringent discharge regulations. A typical ZLD treatment system includes components such as clarifiers, chemical feeds, ultrafiltration, reverse osmosis, and crystallizers tailored to specific contaminants and flow rates. These technologies help recover valuable products from wastewater and improve water quality for reuse in various industrial applications.Presentation on ETP (Effluent Treatment Plant)

Presentation on ETP (Effluent Treatment Plant) Amanuzzaman Aman

╠²

The document discusses the treatment of industrial wastewater in an effluent treatment plant (ETP). It describes the various treatment units used in an ETP including preliminary (screens, grit chambers), primary (sedimentation tanks), secondary (activated sludge process, trickling filters), and tertiary (filtration, activated carbon) treatments. The goal of an ETP is to remove pollutants from wastewater through physical, chemical, and biological processes before discharge or reuse, in order to prevent environmental pollution and protect public health. Major pollutants removed include suspended solids, oil and grease, and organic materials that consume oxygen.Ankit Alankar ETP

Ankit Alankar ETPAnkit Alankar

╠²

This document presents information on an effluent treatment plant (ETP) including the treatment scheme and process. The ETP treats 1500 m3/day of wastewater generated from a company to reduce COD and BOD levels and meet standards for discharge. The treatment process includes screens, equalization tanks, anaerobic hybrid reactors, aeration tanks, lamella clarifier tanks, and final tanks. The ETP aims to reduce pollutants and allow treated water to be safely discharged or reused.Effluent Treatment Plant-Project-02

Effluent Treatment Plant-Project-02Nilusha Rajashilpa

╠²

The document reports on a project to analyze the efficiency, loading capacity, problems, and potential improvements of an effluent treatment plant at Workwear Lanka.

Key findings include:

1. The plant maintains over 90% efficiency in reducing COD levels in effluent. Daily monitoring is needed to maintain efficiency.

2. The equalization tank's loading capacity is 50,000L and helps homogenize waste streams.

3. Common problems include pH variations, froth, and bacterial growth issues. Solutions include improving aeration, dosing, and hydraulic retention times.

4. Potential upgrades include recycling water through tanks multiple times, new flow configurations to improve bacterial activity, and advanced technologies likeZLD fundamentals&design-Lenntech BV

ZLD fundamentals&design-Lenntech BVChristos Charisiadis

╠²

This document serves as a comprehensive guide to the fundamentals and design of zero liquid discharge (ZLD) systems, focusing on brine treatment technologies. It covers various chapters that detail brine properties, conventional treatment methods, ZLD design principles, and brine recovery options with an emphasis on sustainability and cost efficiency. The guide also aims to assist industries in effectively managing brine waste amid increasing regulatory pressures and environmental considerations.Waste Water Treatment Plant

Waste Water Treatment PlantKeshav

╠²

This document summarizes a case study on the Common Effluent Treatment Plant (CETP) in Solapur, India. The CETP treats 3 million liters per day of wastewater from textile industries in Solapur. The treatment process includes preliminary, primary, secondary, and tertiary treatments to reduce parameters like BOD, COD, TSS, oil and grease. After treatment, BOD is reduced by 80% and COD by 95%. However, more treatment is needed to reduce chloride levels in the effluent. The CETP provides effective wastewater treatment for textile industries while reducing individual treatment costs.Effluent treatment plants

Effluent treatment plantsNikhil Kumar

╠²

The document discusses common effluent treatment plants (CETPs), which treat wastewater from multiple industrial plants before disposal or reuse. CETPs allow for economies of scale in wastewater treatment. They address issues like lack of space and provide more consistent treatment than individual plants. However, operating a CETP that receives varied wastewater can be challenging. The document outlines several factors that influence CETP planning and operation, as well as different wastewater treatment technologies, advantages of CETPs, challenges, categories of industries served, effluent treatment steps, conveyance methods, disposal methods, and treated effluent quality standards.common effluent treatment plant

common effluent treatment plantkrishnanand kushwaha

╠²

The document summarizes the operations of a Common Effluent Treatment Plant (CETP) in Baddi, India. The CETP treats 25 million liters of industrial wastewater per day that is collected from over 300 industries through a 62km pipeline network. It categorizes the wastewater into 5 categories based on contamination levels and treats it using various tanks, instruments, and processes like bioaugmentation and chemical preparation. Key operations include equalization, sedimentation, aeration, and tertiary treatment. The CETP aims to reduce environmental pollution through centralized treatment of industrial effluent.ZLD.ppt-Aquatech. Delhi 2015

ZLD.ppt-Aquatech. Delhi 2015satish bhatt

╠²

Zero liquid discharge (ZLD) refers to systems that enable absolute recycling of treated wastewater and conversion of dissolved solids into solid residue through concentration and thermal evaporation. ZLD certification is based on water consumption, wastewater recycled, and solids recovered. Conventional ZLD uses multi-effect evaporation, but this requires high steam consumption. A new technology called polymeric film evaporation uses polymer films as the heat transfer surface, achieving lower operating costs than multi-effect evaporation through reduced steam and power usage. This polymeric film evaporation technology provides benefits like low maintenance and scaling resistance.Membrane process for water treatment

Membrane process for water treatmentMdRomzanAli1

╠²

Microfiltration is an inexpensive water treatment process that uses membranes to reduce turbidity, suspended substances, and bacteria. It has advantages like reducing treatment chemicals and microorganisms while lowering costs compared to conventional treatment. However, it may require pretreatment to prevent fouling and scaling, and membranes require replacement every 3-5 years. Microfiltration is used for water pre-treatment in various biological and membrane processes. Ultrafiltration and nanofiltration can remove even smaller particles and molecules but not salts or sugars. Reverse osmosis uses pressure to force purified water through a semi-permeable membrane, leaving behind dissolved ions and larger particles.Similar to Eig ati 1b (20)

ETP Process Pearl Water Technologies.pptx

ETP Process Pearl Water Technologies.pptxPearl Water Technologies

╠²

Pearl Water Technologies specializes in designing effluent treatment plants (ETPs) for industrial wastewater management, utilizing techniques such as evaporation, centrifuging, filtration, and incineration to ensure safe disposal or reuse. The ETP process involves multiple stages including screening, coagulation, sedimentation, filtration, and disinfection to purify water before distribution. The company offers a range of semi-automatic ETP systems tailored for different industrial needs, aiming to meet regulatory zero-discharge measures and enhance water recycling efficiency.common effluent treatment plant

common effluent treatment plantJay Kumar

╠²

This document provides an overview of common effluent treatment plants (CETP) and industrial wastewater treatment processes. It discusses various sources of industrial wastewater and treatments for removing solids, oils, biodegradable organics, and other contaminants like acids, alkalis, and toxins. Key treatment methods include neutralization, precipitation, filtration, activated sludge processes, and trickling filters. The document focuses on best practices for removing different types of pollutants from wastewater produced by various industries.Effluent from petroleum refineries

Effluent from petroleum refineriesTulsi Makwana

╠²

The document provides an overview of petroleum refineries, detailing their processes, products, and environmental impacts, particularly focusing on wastewater generation and treatment. It notes the significant amounts of water required for refining and highlights the characteristics and treatment methods for wastewater produced during refining. Additionally, it outlines the regulatory standards for effluent and emissions to mitigate the environmental effects of refinery operations.Industrial wastewater treatment

Industrial wastewater treatmentJessaSt1

╠²

The document discusses the key principles and processes involved in industrial wastewater treatment. It begins by outlining the various sources and uses of water in industries and how this leads to wastewater. It then describes the important goals of industrial wastewater treatment as disposal or reuse of effluent while managing water pollution. The document proceeds to detail the major treatment steps, including physical, chemical, and biological processes, and concludes by discussing final disposal methods.Presentation

PresentationAtef Gresat

╠²

The document discusses Ukraine's waste management issues and proposes an alternative solution. It notes that Ukraine accumulates over 14 million tons of household waste annually, and the current waste system does not meet environmental or scientific standards. It then describes a proposed new project that would produce energy resources and materials from municipal waste using a catalytic destruction technology to process organic waste into high-quality and saleable end products like biogas, liquefied gas, diesel and gasoline components, fuel pellets, fertilizers, and construction materials. The proposal argues this system would be self-sustaining with emissions well below limits and economic and environmental benefits over incineration.Aqua silencer

Aqua silencerSalim Malik

╠²

The document describes an aqua silencer designed to reduce noise and toxic emissions from diesel engine exhaust. It incorporates lime water, activated charcoal, and water to purify exhaust gases through chemical reactions and absorption before being released. The aqua silencer consists of a perforated tube surrounded by an activated charcoal layer and immersed in water inside an outer shell. Exhaust first passes through the lime water, then the charcoal layer, which purifies it before the muffled exhaust exits into the water, reducing noise emission. Test results showed the aqua silencer significantly reduced harmful smoke and noise levels compared to a conventional silencer.next step

next stepMenachem Hartman

╠²

AM ITL designs and manufactures industrial filtration systems for swarf handling, effluent treatment, and provides automation solutions to various industries such as oil and gas, mining, and food processing. The company offers a wide range of filtration equipment and services to handle sludge, wastewater, and coolant recycling needs. AM ITL is an engineering company located in Haifa, Israel that has been in business since 1986 providing customized solutions for filtration, pumping, and conveying applications.AF Envirotech Presentation

AF Envirotech PresentationAmit Bhatnagar

╠²

The document discusses the critical role of the environment in human existence and highlights the pervasive issue of pollution due to industrialization and population growth. AF Envirotech offers solutions for treating wastewater and solid waste, emphasizing the importance of water recycling and pollution control. It details the company's experience, technologies for effluent treatment, and the legal framework surrounding water pollution in India.ACE DYNAMICS etp

ACE DYNAMICS etpRAVISHANKAR A

╠²

The document discusses wastewater generation, its types, and the necessity of Effluent Treatment Plants (ETPs) for treating and recycling industrial wastewater. It outlines the key treatment stages including preliminary, primary, secondary, and tertiary treatments, along with technologies such as Fluidized Media Reactors (FMR). Additionally, it emphasizes the importance of ETPs for environmental protection and regulatory compliance.Study of waste water, discharged from tannery (3)

Study of waste water, discharged from tannery (3)Abhishek Rajput

╠²

The document discusses the process of tannery industry and waste generation points. It describes the various stages of hide/skin preparation including soaking, liming, unhairing, splitting, and deliming. The tanning and crusting stages chemically treat the hide to make it stable and flexible. Surface coatings may be applied for finishing. Maximum waste is generated during soaking, unhairing, fleshing, splitting, trimming, bleaching, and bating. The waste water characteristics are provided and treatment schemes discussed including activated sludge and trickling filters. New innovative technologies can more effectively and efficiently treat tannery effluent with lower costs.Filtartaion Techniques-final.ppt

Filtartaion Techniques-final.pptDileepChingan

╠²

This document provides information on various filtration and water treatment systems. It begins with an overview of filtration, describing how it separates solids from liquids using a medium. It then discusses different types of filters including pressure sand filters, activated carbon filters, and ion exchange systems. It explains how these systems work to remove contaminants from water through physical and chemical processes like adsorption and ion exchange. The document also covers membrane filtration technologies like microfiltration and ultrafiltration that remove particles based on their size. It addresses issues like fouling and various cleaning methods for membrane systems.ItookSan1

ItookSan1feridon molaie

╠²

Feridon Molaei is the Managing Director of ItookSanatSehrdadGosare.co, a company that recycles unusable waste from ion-free water production. Their new system can recycle about 93% of waste in the shortest time at the lowest cost. The recycled waste can be reused, saving water. They offer to install their system at petroleum, chemical, and industrial complexes that produce ion-free water and currently lack a waste recycling solution. Ion-free water is important as it removes ions that can damage boilers, decreasing efficiency and potentially causing catastrophic failures.Oil Sands Water Management Initiative Notes

Oil Sands Water Management Initiative Noteswilliampatricklaw

╠²

The document outlines the oil sands water management initiative, discussing various strategies and technologies for managing water resources in oil sands in situ production. It details challenges and advancements in water recycling, treatment, and usage, along with compliance to new regulatory frameworks aimed at sustainability. Key stakeholders from the industry share insights on their current practices, technology reliability, and the importance of understanding groundwater resources to balance environmental stewardship with industrial needs.01. LIKU-TECH - PRODUCTS & SERVICES.ppt

01. LIKU-TECH - PRODUCTS & SERVICES.pptAjayKrishnaM3

╠²

This document provides information about Liku-Tech Environmental Solutions (India) Pvt. Ltd., an Indian company that is part of a German group of companies with over 50 years of experience in water, wastewater, and air treatment facilities and equipment. Liku-Tech India was established 3 years ago to provide environmental solutions in India and Asia Pacific. The company aims to be a leading provider of water, wastewater, and process industry solutions with a high level of quality and integrity. It provides odor control systems, gas scrubbers, biotrickling filters, activated carbon filters, and other waste gas and water treatment equipment.Bioblend presentation tampa

Bioblend presentation tampaconverde

╠²

BioBlend is a full-service environmental consulting company that provides services related to environmental assessment, remediation of petroleum, PCB, and chlorinated solvent contamination, ecological services, compliance monitoring, and more. It has experience using proprietary treatment technologies like activated metal treatment systems and emulsified zero valent iron to remediate contamination from sites in situ. BioBlend's staff includes professionals with expertise in engineering, geology, and environmental science.Bioblend presentation tampa

Bioblend presentation tamparacr2s2

╠²

BioBlend is a full-service environmental consulting company that provides services related to environmental assessment, remediation of petroleum, PCB, and chlorinated solvent contamination, ecological services, compliance monitoring, and more. It has experience using proprietary treatment technologies like activated metal treatment systems and emulsified zero valent iron to remediate contamination from sites in situ. BioBlend's staff includes professionals with expertise in engineering, geology, and environmental science.Wastewater Treatment Refineries

Wastewater Treatment Refineries Ali Safaa97

╠²

The document discusses waste water treatment in oil refineries. It notes that refineries produce a variety of waste materials in gaseous, liquid, and solid forms that must be treated before disposal. Refineries use large amounts of water and generate large volumes of wastewater. Treatment involves using oil skimmers, equalization tanks, trickling filters, aeration tanks, and lagoons/final polishing ponds to treat wastewater before discharge or recycling. The goal is to meet minimum standards for BOD, TSS, pH, and absence of visible solids/oil before treated water is released.ETP.pdf

ETP.pdfKarnav Rana

╠²

The document provides an overview of effluent treatment plants (ETPs), outlining their purpose, design, treatment levels, and mechanisms used for treating industrial wastewater, particularly in the textile industry. It discusses the importance of recycling water to reduce fresh water usage and comply with environmental standards. The document details the various phases of wastewater treatment from preliminary to tertiary levels, including processes such as screening, sedimentation, biological treatment, and advanced methods for improving water quality before discharge.Ad

More from Vladimir (11)

Remediation

RemediationVladimir

╠²

The document summarizes a soil remediation process that uses two technologies:

1) The Terra-Kleen extraction process removes approximately 98% of PCBs from contaminated soil.

2) The Sonoprocess then destroys any remaining PCB residue in the soil through ultrasonic mixing and sodium addition, leaving only non-toxic waste.

The combined process can remediate soils contaminated with pesticides, dioxins, furans, PAHs, and petroleum hydrocarbons in an environmentally-safe way without using heat.Water ionizer

Water ionizerVladimir

╠²

Ionizing water used for well injection can significantly increase oil production and disposal rates. It increases production up to 25% by cleaning formations, removes particles from reservoirs, and recovers oil from produced water. Ionization reduces injection pressure up to 85%, breaks emulsions without chemicals, and removes metals and other contaminants to prepare water for reinjection.Oil ionizer

Oil ionizerVladimir

╠²

The document discusses an oil ionizer technology that can increase revenue from existing oil production in three ways: 1) By increasing the API gravity of crude oil, which can yield thousands of dollars per day or millions per year in additional revenue; 2) By reducing oil content in produced water, allowing recovery of additional barrels of oil per day; 3) By recovering oil from tank bottoms, vessels, and oil lakes using the ionizer. The ionizer technology has been tested internationally and can provide modular, low-cost upgrades to oil production with no chemicals needed.Wet eig new technologies presentation january2010

Wet eig new technologies presentation january2010Vladimir

╠²

The document introduces several technologies for increasing revenue from existing oil and gas production, including an Oil Ionizer and Water Ionizer. The Oil Ionizer recovers oil from produced water and upgrades crude oil quality, increasing revenue by thousands per day. The Water Ionizer enhances water floods by cleaning produced water, reducing injection pressures and increasing production values and revenue by thousands per day. Field tests and examples from companies show ionization increasing well production by 25-77% and reducing costs by treating and reusing water.Weig xtl 11h_sewage

Weig xtl 11h_sewageVladimir

╠²

WET-EIG technology can turn sewage sludge and other low-grade inputs into transportation fuel or power at high conversion rates. It uses gasification and Fischer-Tropsch synthesis to produce diesel or gasoline from sewage sludge and other waste streams in modular plants from 12-600 tonnes per day. The technology offers lower costs than competitors and very low emissions due to operating at cooler temperatures than other gasification processes.Tank recovery 5

Tank recovery 5Vladimir

╠²

The document describes an ionizer sludge recovery system that uses ionized diesel and agitation to separate sludge into crude oil and water. It presents options for progressively larger systems capable of processing 400, 800, 1200, and 2400 barrels per day. The smallest bootstrap system includes two 210-barrel mixing tanks, an ionizer, generator, and related equipment for $86,500. Larger basic and expansion systems add additional tanks, storage, heating, and processing equipment. The largest proposed expansion system is designed for 2400 barrels per day at an estimated cost of $332,200.Petrosonic presentation

Petrosonic presentationVladimir

╠²

The document discusses Petrosonic, a technology that uses sonic and magnetic waves to upgrade heavy crude oil at a lower cost than conventional upgrading methods. It operates at mild temperatures and has no moving parts, requiring lower maintenance than traditional catalytic crackers. Individual Petrosonic modules can process 1000-10,000 barrels per day and upgrade oil from 8-12 API gravity to 24-30 API, increasing its value. Economic analysis shows the technology can increase netbacks for producers by $14-15 per barrel for international heavy crudes and $8-9 per barrel for Canadian crude blends.Ati pogam modified

Ati pogam modifiedVladimir

╠²

This document describes tests of Water Engineered Technologies' (WET) and Aqua Technologies Holdings Inc.'s (ATHI) mechanical/physical process to treat flowback water from Marcellus shale drilling operations. Test A, B, and C showed the process significantly reduced various contaminants like barium, sulfates, iron, total suspended solids, and hydrocarbons in the water. The process uses ionization, filtration with activated clay, and optionally coagulants to treat the water for potential reuse or disposal onsite. Benefits for oil and gas producers include reduced disposal and water acquisition costs as well as environmental impacts.Tank recovery 5

Tank recovery 5Vladimir

╠²

The document describes an ionizer sludge recovery system that uses ionized diesel and agitation to separate sludge into crude oil and water. It presents options for progressively larger systems capable of processing 400, 800, 1200, and 2400 barrels per day. The smallest bootstrap system includes two 210-barrel mixing tanks, an ionizer, generator, and related equipment for $86,500. Larger basic and expansion systems add additional tanks, storage, heating, and processing equipment.Letters of recomendation

Letters of recomendationVladimir

╠²

The document is a letter from Steve Pallister of BP Azerbaijan recommending Water Engineered Technology (WET) for their water filtration and purification systems. BP has used WET's systems for 3 years at their Sangachal Terminal, serving over 5,000 workers. WET has proven themselves with reliable installation, maintenance and monitoring of the systems. Pallister has no hesitation recommending WET's technology and services to other prospective customers.Weig xtl 11h_sewage

Weig xtl 11h_sewageVladimir

╠²

WET-EIG technology can turn sewage sludge and other low-grade inputs into transportation fuel or power at high conversion rates. It uses gasification and Fischer-Tropsch synthesis to produce diesel or gasoline from sewage sludge and other waste streams in modular plants from 12-600 tonnes per day. The technology offers lower costs than competitors and very low emissions due to operating at cooler temperatures than other gasification processes.Ad

Eig ati 1b

- 1. Activated Clay┬«Superior Filtration ŌĆō Long Life ŌĆō Saves Money

- 2. Key benefitsApplications of Activated Clay┬« Highly efficient means of removing hydrocarbons, other oils and chemicals from aqueous solutionsReduces Total Petroleum Hydrocarbons to non-detectable levels. Reduces Oil and Grease to non-detectable levels. Reduces soluble hydrocarbons Benzene, Ethylbenzene, Toluene, and Xylene to barely detectable levels. Loading rate is exponentially greater than Granular Activated Carbon (GAC) Captures 50%-140% its weight in pollutants vs3-10% with GACSaves money of fitrationmediaWonŌĆÖt leach pollutants back into water or any substrateUnlike carbon sponges, Activated Clay wonŌĆÖt spill pollutants pressedEnvironmentally friendlyCan be restored chemically or biologically and reused repeatedlyAlso for Industrial, Agricultural and Maritime applicationsImproves the performance of fuels and working fluids 2

- 3. Proven productSimple & ReliableAqua TechnologiesInc cleans Produced Water Filtration, Closed Loop Water and SoilRemediation Systems, physical Spill Containment, flow through Vertical Trench Barriers, and Underwater flow through Contamination Caps. Activated Clay® manufactured by ATI has unique hydrophobic and oiliophilic characteristics that selectively remove hydrocarbons and a range of organic pollutants from aqueous streams down to extremely low levels. This simple product is simple, reliable & economic.Physical process technologies NO CHEMICAL CONSUMPTIONCost far less to operate than conventional chemical injection processesCreates no by-process wasteATI offers an industry leading off-the-shelf systems that can be easily scaled and transported with flows ranging from 50 GPM to 3000 GPM. 3

- 4. How it worksProduct DevelopmentHistoryIn the late 70ŌĆÖs & early 80ŌĆÖs╠² ATI was in the Oil & Gas Exploration, Drilling and Production business.As necessity is the mother of inventions, an accidental spill required them to contain and remove crude oil from water, soil & rocks.Existing approaches were simple, but ineffective: soap, saw dust, fire or absorbent diapers.ATI then saw the industrial need for a material that would adsorb oil only, but not water.OrganoclaySodium bentonite clay, the basic material in drilling mud and kitty litter, is treated physically and chemically to repel water while absorbing hydrocarbonsOur unique water treatment product, called ET-1, is a product generally referred to as a polymer modified bentonite or an organoclay. ET-1 is manufactured by binding an amine polymer containing an nitrogen ion onto bentonite clay and drying it in a granular form. More specifically, the nitrogen end of the quaternary amine, the hydrophilic end, is positively charged, and ion exchanges onto the clay platelet for sodium or calcium. The amines used are of the long chain type with 12-18 carbon atoms. After some 30 per cent of the clay surface is coated with these amines it becomes hydrophobic and, with certain amines, organophilic.The polymer binds to the bentonite's ionic surfaces and converts the clay from a hydratable form to an oil-wet, hydrocarbon adsorbent material ideal for water treatment applications.4

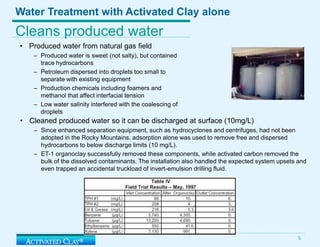

- 5. Water Treatment with Activated Clay aloneCleans produced waterProduced water from natural gas field

- 6. Produced water is sweet (not salty), but contained trace hydrocarbons

- 7. Petroleum dispersed into droplets too small to separate with existing equipment

- 8. Production chemicals including foamers and methanol that affect interfacial tension

- 9. Low water salinity interfered with the coalescing of droplets

- 10. Cleaned produced water so it can be discharged at surface (10mg/L)

- 11. Since enhanced separation equipment, such as hydrocyclones and centrifuges, had not been adopted in the Rocky Mountains, adsorption alone was used to remove free and dispersed hydrocarbons to below discharge limits (10 mg/L).

- 12. ET-1 organoclay successfully removed these components, while activated carbon removed the bulk of the dissolved contaminants. The installation also handled the expected system upsets and even trapped an accidental truckload of invert-emulsion drilling fluid.5

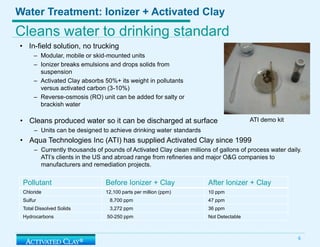

- 13. Water Treatment: Ionizer + Activated ClayCleans water to drinking standardIn-field solution, no trucking

- 14. Modular, mobile or skid-mounted units

- 15. Ionizer breaks emulsions and drops solids from suspension

- 16. Activated Clay absorbs 50%+ its weight in pollutants versus activated carbon (3-10%)

- 17. Reverse-osmosis (RO) unit can be added for salty or brackish water

- 18. Cleans produced water so it can be discharged at surface

- 19. Units can be designed to achieve drinking water standards

- 20. Aqua Technologies Inc (ATI) has supplied Activated Clay since 1999

- 21. Currently thousands of pounds of Activated Clay clean millions of gallons of process water daily. ATIŌĆÖs clients in the US and abroad range from refineries and major O&G companies to manufacturers and remediation projects. ATI demo kit6

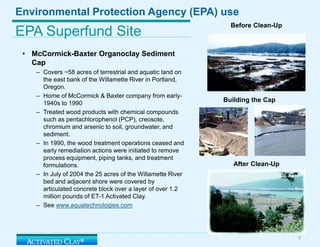

- 22. Environmental Protection Agency (EPA) use Before Clean-Up EPA Superfund Site McCormick-Baxter Organoclay Sediment Cap

- 23. Covers ~58 acres of terrestrial and aquatic land on the east bank of the Willamette River in Portland, Oregon.

- 24. Home of McCormick & Baxter company from early-1940s to 1990

- 25. Treated wood products with chemical compounds such as pentachlorophenol (PCP), creosote, chromium and arsenic to soil, groundwater, and sediment.

- 26. In 1990, the wood treatment operations ceased and early remediation actions were initiated to remove process equipment, piping tanks, and treatment formulations.

- 27. In July of 2004 the 25 acres of the Willamette River bed and adjacent shore were covered by articulated concrete block over a layer of over 1.2 million pounds of ET-1 Activated Clay.

- 28. See www.aquatechnologies.com Building the CapAfter Clean-Up7Activated Clay®

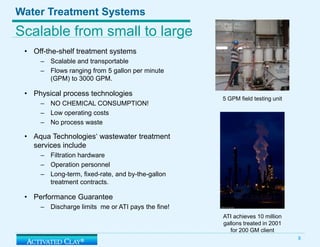

- 29. Water Treatment Systems Scalable from small to largeOff-the-shelf treatment systems

- 31. Flows ranging from 5 gallon per minute (GPM) to 3000 GPM.

- 35. No process waste

- 36. Aqua TechnologiesŌĆś wastewater treatment services include

- 39. Long-term, fixed-rate, and by-the-gallon treatment contracts.

- 41. Discharge limits me or ATI pays the fine!5 GPM field testing unitATI achieves 10 million gallons treated in 2001 for 200 GM client8Activated Clay®

- 42. Activated Clay in Flitration SystemsWater Treatment SystemsTypical wastewater treatment systems have 3 adsorbent containers:

- 43. Primary adsorption vessel containing ET-1 organoclay

- 44. Redundant vessel with 100% back-up quantity

- 45. Polishing container of activated carbon (optional)

- 46. The final polishing step might be eliminated if BTEX or other soluble organics are not an area of concern.

- 47. The container volume and shape determined by:

- 48. Fluid residence time of three minutes per vessel.

- 49. Superficial flow rate of approximately 1.6-2.0 gallons per minute per square ft. (gpm/sq. ft).

- 50. The recommended superficial flow rate

- 52. Specific installations may permit a substantially higher flow rates.

- 53. Residence time is based on an intragranular porosity of 34-39%.

- 54. New installations take advantage of upflow adsorption,

- 55. Existing containers designed for granular activated carbon usually work with ET-1 without modification.9Activated Clay®

- 56. Product SupplyCommercial Units & FactoryActivated Clay┬« is manufactured at ATIŌĆÖs company owned, state of the art manufacturing facility in Casper, Wyoming. ATI is the largest manufacturer of modified clay in the world with over 19,000 sqft of manufacturing space under roof.ATI offers custom packaging for its clients that wish to re-sell, blend or use Activated Clay┬« under different trade names.10Activated Clay┬«

- 57. For further information contactwww.energyinvestgroup.com+44 20 3170 8940Or www.aquatechnologies.com +1 307 234 0009