ELECTRICAL SAFETY. For Education PPT.pdf

- 1. 1 ELECTRICAL SAFETY Systems & International Practices V. Venugopala Rao 19th June,2009

- 2. 2 Statistics †World’s Major Accidents †Causes

- 3. 3

- 5. 5 CAUSES OF FIRE ACCIDENTS †Electrical Faults - 22% †Arson - 10% †Hot Work - 13% †Hot Surfaces - 9% †Smoking - 9 % †Friction, Heat, and Sparks - 7% †Spontaneous Combustion - 5% †Static Sparks -2% †Lightning - 1% †Chemical Action -1% †Miscellaneous -Balance (Sparks , Molten , Burners etc. )

- 7. 7 Strategies †Engineering Standardization †Compliance to Statutes as Bare Minimum Requirement †Updating on BATNEEC (Best Available Technology Not Entailing Excessive Cost) †Aim to Achieve Best International Practices †Knowledge Improvement †Periodical Reviews

- 8. 8 Unsafe Practices „ Bypassing of RCCBs , Fuses, MCBs etc. „ Earthing defects „ Accessible live parts „ Electrical rubber mats „ Wrong identification of equipment / feeders „ Defective electrical portable tools

- 9. 9 Multiple Group of Cables & Excessive Cabling †``If several cables are laid side by side, the spacing between them should be carefully maintained otherwise their current carrying capacities may be seriously effected.’’

- 10. 10 Work Practices †Selection, procurement of standard equipment †Approved Work Practices †Identification & Labeling †Cable Jointing †HT& LT work by competent persons †Use of approved portable equipment †Use of RCCBs for socket outlets for Portable electrical tools †Effective Earthing System †Lockout & Tag out Procedures †Shrouding of Panels †Padlocking the panels

- 11. 11 Work Practices (contd) †Use of Positive Interlocks †International Colour Coding Practices †Lightening Protection †Appropriate Cable Routing †Provision of Drawings near Panels

- 12. 12 Work Practices (contd) „ Storage of combustible materials near electrical equipment / fuse units „ Direct supply from socket „ No Master Isolation Switch outside warehouses „ Improper cable joint procedures / Taped joints „ Earthing defects „ Use of non-standard fuse wires „ Bypassing of protection devices „ Deteriorated insulation

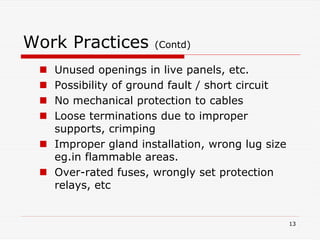

- 13. 13 Work Practices (Contd) „ Unused openings in live panels, etc. „ Possibility of ground fault / short circuit „ No mechanical protection to cables „ Loose terminations due to improper supports, crimping „ Improper gland installation, wrong lug size eg.in flammable areas. „ Over-rated fuses, wrongly set protection relays, etc

- 14. 14 Circuit Line Diagrams „ Unauthorized Temporary Installations? „ Updated? „ SLD reflects the actual installation? „ Duly approved by statutory authorities?

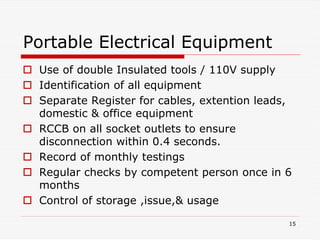

- 15. 15 Portable Electrical Equipment †Use of double Insulated tools / 110V supply †Identification of all equipment †Separate Register for cables, extention leads, domestic & office equipment †RCCB on all socket outlets to ensure disconnection within 0.4 seconds. †Record of monthly testings †Regular checks by competent person once in 6 months †Control of storage ,issue,& usage

- 16. 16 Work on Electrical Installations †Isolation of equipment with isolators locked †Work on high voltage with authorized persons only †Presence of 2 fully competent persons †Cordoning of area †All work must be fully documented with modifications noted

- 17. 17 Earthing „ Installation as per approved design? „ Installation and Maintenance as per IS 3043? „ Earth resistance measured periodically? „ Test procedure „ Acceptable earth resistance values „ Is the earthing system modified when electrical installation is modified? „ Are neutral earth pits independent and separate? „ Are earth pits identified? „ Are two and distinct earth connections provided? „ Is the earth continuity tested? „ Is bonding and earthing carried out to avoid ES hazards?

- 18. 18 Lightning Protection „ Lightning protection system as per IS 2309? „ Numbers of down conductors direct and adequate? „ All the structures and building under the zone of protection? „ While reviewing lightning protection, both the plan and elevation of structures, etc. considered? „ Earthing for the electrical and lightning systems Sepearte „ Storage tanks / chimneys and other special structures protected? „ Earth electrodes- maintenance / periodic tests / acceptable value „ Awareness of basic concepts of lightning such as types of lightning, predictability factor, protection concepts, etc

- 19. 19 Hazardous Areas „ Hazardous areas classified as per IS 5572? „ Electrical equipments maintained as per IS 2148 and IS 13346? „ Review of area classification in case of process change / plant modification, etc. „ Approval of area classification drawings as per statutory rules „ Maintenance of flame-proof equipments „ Use of ordinary electrical equipment in hazardous areas „ Awareness of O&M personnel about hazardous area and flame-proof equipments

- 20. 20 Statutory Compliance • Applicability of Rules • Compliance to inspector’s reports • Submission of accident intimation reports, forms, etc. in time • Intimation of inspector before energizing new / changed electrical installation

- 21. 21 Electrical Preventive Maintenace „ EPM programme in place? „ Is the programme implemented? What is the slippage? „ Are the relevant standards (statutes and non-statutory) referred and incorporated in the EPM programme? „ Electrical Tests, Records, Test Procedure and periodicity (earth resistance, insulation resistance tests) „ EPM programme only documented? „ Transformer tests (dielectric strength, acidity, sludge deposits, dissolved gases, etc.) and periodicity „ Periodic calibration of meters (ammeter, voltmeter, relays, temperature gauges) and test instruments (insulation resistance megger, earth resistance megger, multi-meters, etc.)

- 22. 22 Review of Electrical Accidents „ Every accident / near-miss electrical accidents investigated in detail? „ Root cause identified and included in the APP (Accident Prevention Programme)? „ Are the recommendations incorporated in the O&M procedures/ work permit „ Are these accident causes given importance in safety training sessions? „ Are the hazard identification techniques such as job safety analysis, Fault Tree Analysis, etc. utilized?

- 23. 23 Energy Conservation †Adoption of Energy Efficient Units. Eg. Electroflow,Variable Frequency Drives †Mechanical & Electrical Preventive Maintenance systems especially bearings & alignment of M/Cs †Energy Saving Practices

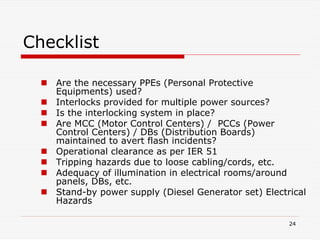

- 24. 24 Checklist „ Are the necessary PPEs (Personal Protective Equipments) used? „ Interlocks provided for multiple power sources? „ Is the interlocking system in place? „ Are MCC (Motor Control Centers) / PCCs (Power Control Centers) / DBs (Distribution Boards) maintained to avert flash incidents? „ Operational clearance as per IER 51 „ Tripping hazards due to loose cabling/cords, etc. „ Adequacy of illumination in electrical rooms/around panels, DBs, etc. „ Stand-by power supply (Diesel Generator set) Electrical Hazards

- 25. 25 Clause in Purchase Order ``The Party should comply with the Environment ,Health & Safety Requirements attached to this PO,relevant to their supply of Machinery/equipment’’

- 26. 26 Contractor Controls †Safety Checks of Contractors’ tools †Incorporating EHS Clause in Work Order and Acknowledgement ``The Contractor should comply with all Environment ,Health & Safety requirements of the company and local statutory regulations at the work site and they deem to accept this clause upon undertaking the work .’’

- 27. 27 Important International Recommendations †Electrical systems are to be surveyed and the results documented at least every five years. †High voltage systems must be surveyed and the results documented at least every four years. †All electrical systems are to be fitted with the best international safeguards, critical systems must be checked monthly and documented. †All modifications and additional systems are to be approved and documented. †Electrical work must only be carried out by authorised electrical personnel. †Portable electrical, including personal and contractors, equipment must be approved, registered, coded and checked at least once per year.

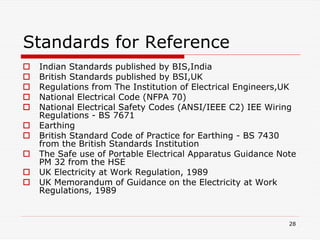

- 28. 28 Standards for Reference †Indian Standards published by BIS,India †British Standards published by BSI,UK †Regulations from The Institution of Electrical Engineers,UK †National Electrical Code (NFPA 70) †National Electrical Safety Codes (ANSI/IEEE C2) IEE Wiring Regulations - BS 7671 †Earthing †British Standard Code of Practice for Earthing - BS 7430 from the British Standards Institution †The Safe use of Portable Electrical Apparatus Guidance Note PM 32 from the HSE †UK Electricity at Work Regulation, 1989 †UK Memorandum of Guidance on the Electricity at Work Regulations, 1989

- 29. 29 Thank You V.Venugopalarao In case of any queries /consultation ,please contact On Mobile : +91-98480 21365