Emulson AG/TP1: Acrylic Polymer Dispersant from Lamberti

- 1. EMULSON AG/TP1 THE AQUEOUS CONCENTRATE OF ANIONIC ACRYLIC COMPOUND

- 2. Chemical Description ’é¦ Aqueous dispersion (colloidal solution) of anionic acrylic polymer ’é¦ Copolymer of alkylmethacrylate and AMPS ’é¦ Low molar content of hydrophobic monomer (alkylmethacrylate) ’é¦ Random distribution of structure units ’é¦ Similar to comb-like (grafted) polymer

- 3. Structure of AMPS ’é¦ AMPS: Acrylamido- methyl-propane sulfonate H N SO3H O

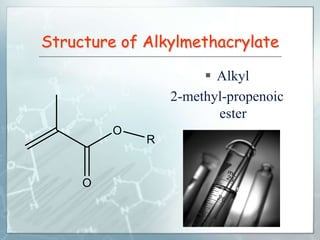

- 4. Structure of Alkylmethacrylate ’é¦ Alkyl 2-methyl-propenoic ester O R O

- 5. Random Distribution of Three Linkages ’é¦ Monomer A - Monomer A ’é¦ Monomer A - Monomer B ’é¦ Monomer B - Monomer B

- 6. Structures O O ’é¦ WhatŌĆÖs the right Me OR Me OR structure?? NHR NHR O O ’é¦ A polymer with idrophobic and idrophilic groups

- 7. Specification (properties in certificate of analysis) ’é¦ Milky dispersion ’é¦ pH (indiluted form): 5 ’é¦ Low viscous liquid: <1000 mPa.s at 20 ┬░C using Brookfield

- 8. Functions to be recognised ’é¦ Dispersant to dispers solid particles or liquid droplets in continuous phase ’é¦ Multi ancor points leads to strong (irreversible) adsorption ’é¦ Building of steric barrier and behaviour of polyelectrolyte (electrostatic repulsion) ’é¦ Reducing viscosity ’é¦ Compatibility agent ’é¦ Milling aids: easy grinding

- 9. Like Polyelectrolyte ’é¦ Hydrophilic monomer (AMPS) consists of sulfonic group ’é¦ High molar ratio of AMPS provides high charge density ’é¦ Sulfonic groups are neutralised (sodium salt); full dissociation particularly in pH >7

- 10. Dispersion ŌĆō Colloidal Solution ’é¦ Sulfonic groups (in AMPS monomers) improve solubility of copolymer in water, ’é¦ Alkyl chains (in methacrylate monomers) improve the adsorption and accumulation at polar/apolar interface ’é¦ Due to relatively high molecular weight of copolymer , solubility characteristics of monomers and molar ratio the aqueous colloidal solution is being produced

- 11. Application ’é¦ Product can be used in aqueous dispersions (mainly aqueous suspension concentrate SC) or in preparation of slurry to be spray dried ’é¦ as dispersant or co-dispersant (in combination with other polymer and/or traditional surfactant) ’é¦ as milling aid

- 12. Application and Guides for SC ’é¦ Usually 2-5 % Emulson AG/TP1 gives desired results (regarding suspension stability, rheological characteristics) ’é¦ Good compatibility with other anionic coformulants (phosphates, sulfonates) ’é¦ Good compatibility with non-ionic alkoxylates (ethoxylates, EO/PO adducts) ’é¦ Good compatibility with xanthan gum

- 13. SC Formulations of following Active Ingredients were examined obtaining suitable results Inorganic solid actives ’é¦ Bordoeaux Mixture ’é¦ Copper oxychloride ’é¦ Sulfur Organic solid actives ’é¦ Diuron ’é¦ Fluometuron ’é¦ Bendiocarb

- 14. Advantages ’é¦ High tolerance to extreme conditions of ionic strength and temperature ’é¦ Ideal for solvent-free aqueous system including SUSPENSIONS (slurries) ’é¦ Usualy no wetting agent required

- 15. Theta Conditions ’é¦ Using NaCl (4M), CaCl2 (1M)and Na2SO4 (2M) the salt tolerance is excellent: no flucculation, precipitation occur ’é¦ Heating up to 70 ┬░C no flucculation and noincrease in viscosity