Energy Audit Results Presentation

- 1. DS TEXTILE AUDIT By PITCO (Pvt.) Ltd.

- 2. Name Plate Data Three phase Induction Motor Main Motor Data Power 22 KW Voltage 400 V Current 39.2 A Frequency 60 Hz Connection ? (Delta) Insulation Class B Weight 215 KG

- 3. Motor Measured Data Motor Voltage Current PF KW KVAR KVA No. (Volt) (Amp) 1 405.4 16 0.774 8.7 7.7 11.67 2 419 14.1 0.76 7.9 7.6 10.1 7 415.8 20.2 0.831 12.58 8.45 14.85 8 399.9 25.5 0.774 11.38 9.7 14.99 9 394.6 16.8 0.857 9.654 5.88 11.55 10 394.4 15.5 0.87 9.2 5.3 10.7 11 394.8 17.3 0.816 9.63 6.76 11.9 25 423 16.3 0.75 9 7.6 11.9 41 417.6 20.3 0.65 10.98 12.85 17.3 56 413.4 25.1 0.44 7.8 15.66 17.9 Note: Motor No. 41 & 56 are DOL (Direct On Line)

- 4. Percent Load = (Running KW/ Rated KW) ¡Á 100 Motor Number Running KW Rated KW % Load 1 8.7 22 39.54 2 7.9 22 35.91 7 12.58 22 57.18 8 11.38 22 51.72 9 9.654 22 43.88 10 9.2 22 41.81 11 9.63 22 43.77 25 9 22 40.91 41 10.98 22 49.91 56 7.8 22 35.45

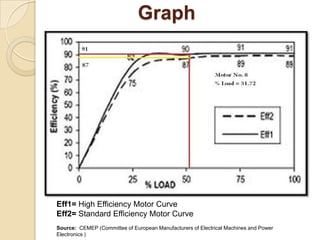

- 5. Graph between Load (%) and Efficiency (%) Eff1= High Efficiency Motor Curve Eff2= Standard Efficiency Motor Curve Source: CEMEP (Committee of European Manufacturers of Electrical Machines and Power Electronics )

- 6. Graph Eff1= High Efficiency Motor Curve Eff2= Standard Efficiency Motor Curve Source: CEMEP (Committee of European Manufacturers of Electrical Machines and Power Electronics )

- 7. Rewinding ? All motors in the industry were rewound. Most of them were rewound twice and some even thrice. ? Rewinding once reduces the efficiency from 2 to 3 percent. ? The cost of rewinding is 65% of the initial motor cost. ? All the motors were more than 20 years old which is more than their normal life span.

- 8. Calculations KWsaved = L ¡Á KWRated ¡Á [( / Effold motor) ¨C ( /Effnew motor)] ¡Á 00 KWhsavings = KWsaved ¡Á Annual Operating Hours Operating Hours = (365¡Á 24) ¨C [10% of (365 ¡Á 24)] = 7884 hrs Total Savings (Rupees) = KWhsavings ¡Á Unit Charges (Rupees/KWh) L = Load Factor Effold motor = Standard Motor Efficiency(Eff2) Effnew motor= High Efficiency Motor Efficiency(Eff1) ? The extra cost of an energy efficient motor is often quickly repaid in energy savings.

- 9. Payback ? Time required for the savings to equal the initial cost. Simple Payback = Motor price Annual Savings ? Operational cost is about six times its initial purchase. ? Purchase price of Energy Efficient motor is 15% to 30% more than standard motor that can be recovered within 2 years.

- 10. Results

- 11. Conclusion Total KW in operation 96.824 No. of Motors 10 Total KW saved 12.643 Total Saving (Rupees) 996812 Total Investment (Rupees) 2870350 50% off Price 1435175 Payback Time 1year 6 months Hence from these facts and figures, replacement of all the motors is recommended

![Calculations

KWsaved = L ¡Á KWRated ¡Á [( / Effold motor) ¨C ( /Effnew motor)] ¡Á 00

KWhsavings = KWsaved ¡Á Annual Operating Hours

Operating Hours = (365¡Á 24) ¨C [10% of (365 ¡Á 24)] = 7884 hrs

Total Savings (Rupees) = KWhsavings ¡Á Unit Charges (Rupees/KWh)

L = Load Factor

Effold motor = Standard Motor Efficiency(Eff2)

Effnew motor= High Efficiency Motor Efficiency(Eff1)

? The extra cost of an energy efficient motor is often quickly repaid in energy

savings.](https://image.slidesharecdn.com/presentation-120601064908-phpapp01/85/Energy-Audit-Results-Presentation-8-320.jpg)