Entertainment Engineering Dancing Water Story

- 2. Entertainment MANUF ACTURING Engineering & THEATRE VOLUME 8 ISSUE 10 Persun & Wiebusch, Inc. A few months ago in this column, I talked about the connection between manufacturing and movies, highlighting Publishers/Editors: how manufacturing companies enabled movies like Fast Five with various technologies: hydraulics, software, and electronics to name Terry Persun a few. This month, we are going to show you that the same thing is P: 360-732-0902 true within another entertainment industry: theatre. In a special three-part story later in this issue, you can read how E: terry@entertainmentengineering.com Parker Hannifin (Mayfield Heights, OH), Delta Computer Systems Bruce Wiebusch (Seattle, WA) and other manufacturing based companies are enabling the WorldˇŻs largest water-based show ˇŞ House of Dancing P: 440-503-3013 Water ˇŞ in Macau, China. E: bruce@entertainmentengineering.com Design & Production: Verv Creative www.vervcreative.com Editorial Contributors: Dan Cook, Ph.D., Program Coordinator, Entertainment Engineering and Design, UNLV Gerald Braude S. Korobeinik Richard Mandel Mark Persun Editorial Board: From our exlusive interview with show producer Patrice Bilodeau, we discovered how Franco Dragone Entertainment Greg Hale, VP Advanced Technology GroupˇŻs House of Dancing Water is an event enabled by many Disney Parks and Resorts engineers from many differeent counties, including Jacek Kaminski P. Eng. Chief Engineer and Eng. Manager for City of Dreams Kevin Russelburg, Sr. Project Engineer Project for Handling Specialty Manufacturing Ltd. (Grimsby, ITW Pancon Ontario, Canada). John Lewis, Sr. Writer, Cognex Corp. Control Motion Solutions, Inc. (Santa Ana, CA), a.k.a. COMOSO, was the hydraulics distributor for the project, and Fisher Technical Services, Inc. (Las Vegas, NV) was important to Sales the project success. Many of the companies involved are heavily involved with manufacturing of many types of products outside the Mark Wiebusch entertainment industries. Vice President, Media Solutions & Sales P: 440-835-9733 For more information on the show, visit: markw@entertainmentengineering.com http://thehouseofdancingwater.com/en/#/home. Bruce Wiebusch Subscriptions: bruce@entertainmentengineering.com www.EntertainmentEngineering.com www.entertainmentengineering.com 3

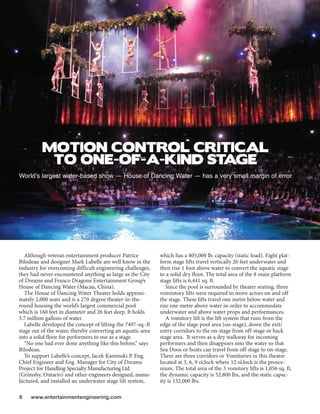

- 3. MOTION CONTROL CRITICAL TO ONE-OF-A-KIND STAGE WorldˇŻs largest water-based show ˇŞ House of Dancing Water ˇŞ has a very small margin of error Although veteran entertainment producer Patrice which has a 805,000 lb. capacity (static load). Eight plat- Bilodeau and designer Mark Labelle are well know in the form stage lifts travel vertically 26 feet underwater and industry for overcoming difficult engineering challenges, then rise 1 foot above water to convert the aquatic stage they had never encountered anything as large as the City to a solid dry floor. The total area of the 8 main platform of Dreams and Franco Dragone Entertainment GroupˇŻs stage lifts is 6,441 sq. ft. House of Dancing Water (Macau, China). Since the pool is surrounded by theater seating, three The House of Dancing Water Theater holds approxi- vomintory lifts were required to move actors on and off mately 2,000 seats and is a 270 degree theater-in-the- the stage. These lifts travel one metre below water and round housing the worldˇŻs largest commercial pool rise one metre above water in order to accommodate which is 160 feet in diameter and 26 feet deep. It holds underwater and above water props and performances. 3.7 million gallons of water. A vomitory lift is the lift system that runs from the Labelle developed the concept of lifting the 7497-sq.-ft edge of the stage pool area (on-stage), down the exit/ stage out of the water, thereby converting an aquatic area entry corridors to the on-stage from off-stage or back into a solid floor for performers to use as a stage. stage area. It serves as a dry walkway for incoming ˇ°No one had ever done anything like this before,ˇ± says performers and then disappears into the water so that Bilodeau. Sea Doos or boats can travel from off-stage to on-stage. To support LabelleˇŻs concept, Jacek Kaminski P. Eng. There are three corridors or Vomitories in this theatre Chief Engineer and Eng. Manager for City of Dreams located at 3, 6, 9 oˇŻclock where 12 oˇŻclock is the prosce- Project for Handling Specialty Manufacturing Ltd. nium. The total area of the 3 vomitory lifts is 1,056 sq. ft, (Grimsby, Ontario) and other engineers designed, manu- the dynamic capacity is 52,800 lbs, and the static capac- factured, and installed an underwater stage lift system, ity is 132,000 lbs. 6 www.entertainmentengineering.com

- 4. Handling Specialty engineered and installed all of the or levelness. One of the greatest engineering challenges, systems required to complete the controls, hydraulics, according to Bilodeau, was having the control system structure, skirting, guides, and astragals. Astragals are perform reliably over time. shear zone safety protection devices that are installed all ˇ°We have two shows per day and operate five days per around the underside of every edge of every lift. Their week,ˇ± explains Bilodeau. ˇ°Every time the stage moves, purpose is to immediate halt motion should the edge of the control system has to operate with a precision of any lift encounter an obstacle such as a piece of scenery within 5 mm.ˇ± or a performer. RMC150E series of controllers from Delta Computer Six hydraulic power units from Parker Hannifin Systems (Battle Ground, WA) were chosen to perform (Mayfield Heights, OH) are used to actuate the lifts. the task of controlling the 32 hydraulic cylinders that An electronic controls system enables the lifts to move move the sections of the main stage in the theater. ˇ°The independently or in synchronization. The total dynamic controller provided many feedback options and were capacity of the main lifts is 322,000 lb. able to interface with our magnetostrictive linear dis- The control system is continuously fed with informa- placement transducers without the need for signal con- tion from each cylinder to tell it where they are in their ditioners,ˇ± says Beach. ˇ°The software provided was found stroke path. The computers can receive the signals and to be user friendly and a very powerful setup and tuning instantly alter the flow of fluids into the cylinders so as tool.ˇ± to keep them all level or to run any number at different While the electromechanical motion controllers used speeds with different targets and so on. by Handling Specialty in the past considered only speed ˇ°All of the safety mechanisms such as the astragals, are and position, the Delta Computer Systems controller monitored in real time with the computers so that opera- now permitted pressure to be part of the equation and tors know the system is in a safe operating condition,ˇ± anticipated the motion of a hydraulic system. says Tom Beach, president of Handling Specialty. ˇ°The computers also can change the flow rate and the speed of For More Information Click Below: the lifts in either direction so operators can create very Handling Specialty Home > special EFX with the motion control.ˇ± Handling Specialty Turnkey Capabilities > Electronic probes integral of the cylinders provide Handling Specialty Entertainment Solutions > the I/O feedback that the computers need in order to House of Dancing Waters > maintain full control of speed, distance, ramping, targets HOUSE OF DANCING W TER CONTROLLERS A Eight platform stage lifts travel vertically 26 feet frames and keep the platforms perfectly flat at all times. underwater and then rise one foot above water to con- The Delta controllers support a special synchronization vert an aquatic stage to a solid dry floor in the House function for this purpose. The motion of each cylinder of Dancing Water theatre (Macau, China). When the is tightly controlled to follow commands from a ˇ°masterˇ± 6,441 sq. ft platforms transition from traveling through air to traveling through the water, the hydraulic system must adapt to the huge drag from the water. The unique hydraulic system parameters and algorithms provided in the Delta Computer Systems controllers were up to the task. A dozen Delta RMC150 electro-hydraulic motion con- trollers were used to control the hydraulic cylinders that moved the eight stage platforms and three stage entrance hallway platforms. Each of the moving platforms is lifted by four long Parker-Hannifin hydraulic cylinders, one at each corner. Closed-loop motion control is required for two main reasons: 1) The motion of the four cylinders on each platform needs to be synchronized to ensure that they all move by the same amount, to avoid racking of the platform www.entertainmentengineering.com 7

- 5. project, and Fisher Technical Services, Inc. (Las Vegas, NV) was involved with integrating the controls. Delta assisted with the programming and tuning of the system and worked closely with MTS, Fisher Technical Services, and Comoso to help with the integration process, which included the HPU, plumbing, control enclosures and the full integration into the theater. COMOSO cus- tom designed the hydraulic system and its plumbing and worked with Parker Hannifin (Cleveland, OH) to design a custom servo cylinder for the main plat- forms. Additionally, COMOSO utilized Fisher Technical Services to provide and integrate the control hardware and tuning for the entire system. As you know the system consisted of eight underwa- ter lifts making up the main platform. These lifts are capable of independent operation, or gearing together PLC. The MTS transducers provide the position infor- in any way imaginable. Additionally the VOM lifts were mation on each cylinder to enable the Delta controllers independently controlled, yet were capable of gearing to close the control loop. Each RMC150 can control up themselves to its adjacent main platform to create a seam to eight hydraulic axes, but each one is handling four at their edges. The Main Lift cylinders were controlled axes in the Dancing Waters application. by remote valve stands located in the basement of the 2) Closed-loop motion control is also needed to com- theater, beneath the pool floor itself. pensate for the compressibility of the large volumes of Jeff Potter and Matt Schoenbachler from COMOSO hydraulic oil that are used in the 30-foot-long cylinders. and Vic Trujillo from Fisher Technical Services also A second-order equation is used in the control loop to made significant contributions to the project. enable damping of the transient effects that occur when the motion starts and stops. Control commands are For More Information Click Below: provided from the Delta RMC directly to servo-quality Delta Computer Systems Home > proportional hydraulic valves. This ensures that the plat- Delta Motion Controllers > forms move smoothly with no oscillations. Parker Hannifin Home > Control Motion Solutions, Inc. (Santa Ana, CA), Parker Products > a.k.a. COMOSO, was the hydraulics distributor for the HOUSE OF DANCING W TER HYDRAULICS A Greg Paddock, Hydraulic Territory Manager, at Parker Hannifin CorporationˇŻs Hydraulics Group explains below the critical role hydraulics played in the stageˇŻs motion control system 8 www.entertainmentengineering.com

- 6. The design and component selection for the HPU was critical with regard to the overall success of the project. The HPU had to be capable of providing smooth, ripple free flow without response lag whether there was motion demand from only one of the small vomitory stages, or from all of the large main stages working in unison. Fourteen Parker PV270 variable volume piston pumps responded precisely to any system flow demand regard- less of the magnitude and rate of the motion profile required by the stages collectively, or independently. The PV270ˇŻs extremely fast on and off stroke response (< 85 msec & < 75 msec respectively) were key to the stability of the pressure and flow supplied to the servo axisˇŻ. With recommendations on component selection from Parker personnel, Comoso integrated all of the HPU components into a highly engineered HPU with two key design challenges presented to them. One, the electri- cal power available for the HPU was limited so overall rod and piston seals where necessary to ensure the criti- system efficiency was a key design criteria in component cal performance of the cylinders. selection, and two, the fact that the HPU had to physi- The Parker D41FH Proportional/servo valves were cally fit through a very limited access galley to where the final critical elements in the stage motion and con- the HPUˇŻs would be permanently located. It was decided trol loop. The stability of the D41FH and extremely that the HPU would be designed in a modular configu- high dynamic response were key to maintaining the ration with two symmetrical halves and then reconnect- commanded cylinder motion profiles demanded by the ed once in their final installation location. Mark Force director of the show. The stage design did not allow for and Matt Schoenbachler of Comoso exceeded everyoneˇŻs a mechanical means to ensure that each cylinder would expectations with the HPU design and layout. maintain a level position relative to the other three The 32 Parker custom designed and built cylinders cylinders supporting each corner of the eight stages, where designed specifically in order to accommodate therefore each cylinder had to be precisely controlled via the extreme environmental conditions and challenges of electronic magnetostrictive feedback devises, Delta digi- this application which included continuous submersion tal motion controllers and Parker D41FH proportional/ in chlorinated pool water, load induced side loads on servo valves to ensure all of the cylinders on each stage the cylinder rods, and very low friction seals which were maintained highly precise synchronized motion profiles necessary to achieve the desired motion profile of the relative to each other. This required complex external stages. Special coatings, stainless steel rods, a proprietary position and velocity loop control as well as a valve process to achieve the cylinder rod finish, and special capable of carrying out the precise system commands to ensure each cylinder maintained their desired motion profile. A series of dynamic performance calculations were carried out by Parker Hydraulic Systems Engineer, Rich Duder to ensure proper valve selection and sizing as well as predicting overall loop stability. The valves also provided a number of key safety elements which were of paramount importance for the overall system design as there are live actors and support personnel underwater, above and below the stages while the stages are in motion during performances. The D41FH spring centered servo spool with mechanically adjustable bias insured that upon an emergency abort event or power outage the stages would come to a rapid and predictable safe stop without fail. This helped to ensure the safety of all show personnel. For More Information Click Below: Delta Computer Systems Home > Handling Specialty Home > Parker Hannifin Home > Parker Hydraulic Products > www.entertainmentengineering.com 9