Enviro test training-deck

- 1. Q.I. MEDICAL, INC. EnviroTestTM Training

- 2. EnviroTestTM âĒ Used for monitoring the microbiological quality of controlled environments and compounding personnel

- 3. EnviroTestTM is available in two media formulations Trypticase Soy Agar (TSA) for general microbial contamination ET1000 âĒ The TSA of the ET100 is supplemented with lecithin and polysorbate 80 to inactivate residual disinfecting agents on surfaces â allows best microbial recovery âĒ Also known as Microbial Content Test Agar, this medium is shown to be as nutritive as TSA

- 4. EnviroTestTM is available in two media formulations âĒ Malt Extract Agar (MEA) for targeting yeast, mold, and fungal contamination âĒ Includes antibiotics to reduce bacterial overgrowth of fungal colonies ET3000

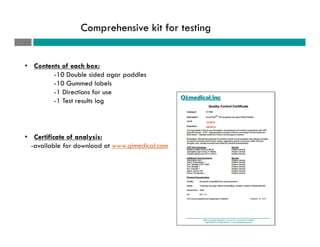

- 5. Comprehensive kit for testing âĒ Contents of each box: -10 Double sided agar paddles -10 Gummed labels -1 Directions for use -1 Test results log âĒ Certificate of analysis: -available for download at www.qimedical.com

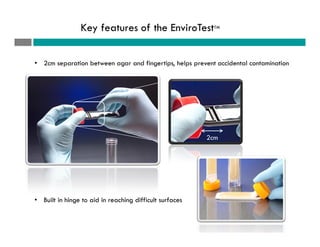

- 6. Key features of the EnviroTestTM âĒ 2cm separation between agar and fingertips, helps prevent accidental contamination 2cm âĒ Built in hinge to aid in reaching difficult surfaces

- 7. ïĻ Follow guidelines set forth in USP chapter <797> ïĻ USP chapter <1116> also a good reference in establishing protocols ïĻ Outsourcing facilities should review CGMPs for specific testing requirements Proper testing is critical for sterile compounding

- 8. ïĻ Testing gloved fingertips and thumb prints of both hands immediately after gowning/garbing ïĻ Test key surface areas of compounding environment (Hoods, Pass thrus, Carts, Shelving) ïĻ Test surfaces of key components (Handles, buttons, key pads) ïĻ Frequency of testing see USP <797> for minimum requirements Key factors in a sampling plan *Information references common practice based on feedback. For specific requirements/recommendations see USP <797> and USP <1116>

- 9. Developing a written sampling plan Ante Room Buffer Room LAFWLAFW LAFW ISOLATOR Counter Shelving Pass Thru Cart Shelving Pass Thru Door Door = Surface Sampling *Diagram is meant to illustrate an example sampling plan. Each facility will vary in terms of layout = Gloved Fingertip Sampling âĒ Must include sterile gloved fingertips and ALL ISO classified areas âĒ Clean surfaces after testing with 70% IPA and non-shedding wipe Door Knob Wall Floors

- 10. EnviroTestTM is ideal for meeting sampling requirements High traffic entrance button Pass Thru surface

- 11. EnviroTestTM can access hard to reach areas better Front and backside pass thru handle that is curved could easily harbor bacteria

- 12. EnviroTestTM can access hard to reach areas better Pass Thru handle on barrier isolator

- 13. Commonly used plates cannot access the same areas Plates are also awkward to handle in these areas Gap

- 14. Hinge makes testing high traffic areas easy Isolator button Floor area Key pad panel

- 15. EnviroTestTM is superior in testing corners of hoods Air circulation within hoods often deposits particles in the edges and corners of the hood where a circular plate cannot reach

- 16. Edges are another issue for plates Recessed surface of a plate makes it impossible to access raised edges Gap

- 17. Place paddle in tube and incubate USP <797>: Temperature and duration vary depending on agar used âĒ ET1000: 30-35šC for 48-72 hours (2-3 days) âĒ ET3000: 26-30šC for 120-168 hours (5-7 days)

- 18. Observe and document results âĒ Positives (if any), Number of colonies (CFU) âĒ Identification of Microorganisms âĒ Evaluate and implement corrective action if necessary

- 19. Disposal âĒ Discard in a manner consistent with State & Federal regulations as this may vary

- 20. ïĻ Q.I. Medical would like to thank Mercy San Juan Hospital Pharmacy Department for the use of their time and facility during this process Special Thank You