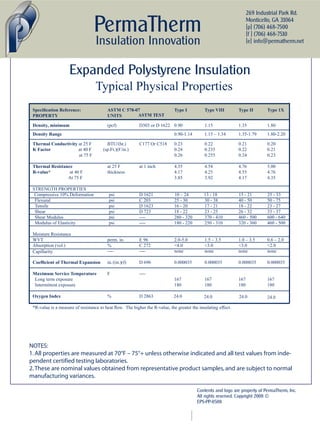

Permatherm Expanded Polystyrene Physical Properties

- 1. 269 Industrial Park Rd. PermaTherm Monticello, GA 31064 {p} (706) 468-7500 {f } (706) 468-7510 Insulation Innovation {e} info@permatherm.net Expanded Polystyrene Insulation Typical Physical Properties Speci?cation Reference: ASTM C 578-07 Type I Type VIII Type II Type 1X PROPERTY UNITS ASTM TEST Density, minimum (pcf) D303 or D 1622 0.90 1.15 1.35 1.80 Density Range 0.90-1.14 1.15 ¨C 1.34 1.35-1.79 1.80-2.20 Thermal Conductivity at 25 F BTU/(hr.) C177 Or C518 0.23 0.22 0.21 0.20 K Factor at 40 F (sp.Ft.)(F/in.) 0.24 0.235 0.22 0.21 at 75 F 0.26 0.255 0.24 0.23 Thermal Resistance at 25 F at 1 inch 4.35 4.54 4.76 5.00 R-value* at 40 F thickness 4.17 4.25 4.55 4.76 At 75 F 3.85 3.92 4.17 4.35 STRENGTH PROPERTIES Compressive 10% Deformation psi D 1621 10 ¨C 24 13 - 18 15 - 21 25 - 33 Flexural psi C 203 25 - 30 30 - 38 40 - 50 50 - 75 Tensile psi D 1623 16 - 20 17 - 21 18 - 22 23 - 27 Shear psi D 723 18 - 22 23 - 25 26 - 32 33 - 37 Shear Modulus psi ---- 280 - 320 370 - 410 460 - 500 600 - 640 Modulus of Elasticity psi ---- 180 - 220 250 - 310 320 - 360 460 - 500 Moisture Resistance WVT perm. in. E 96 2.0-5.0 1.5 ¨C 3.5 1.0 ¨C 3.5 0.6 ¨C 2.0 Absorption (vol.) % C 272 <4.0 <3.0 <3.0 <2.0 Capillarity ---- ---- none none none none Coef?cient of Thermal Expansion in./(in.)(f) D 696 0.000035 0.000035 0.000035 0.000035 Maximum Service Temperature F ---- Long term exposure 167 167 167 167 Intermittent exposure 180 180 180 180 Oxygen Index % D 2863 24.0 24.0 24.0 24.0 *R-value is a measure of resistance to heat ?ow. The higher the R-value, the greater the insulating effect. NOTES: 1. All properties are measured at 70ˇăF ¨C 75ˇă+ unless otherwise indicated and all test values from inde- pendent certified testing laboratories. 2. These are nominal values obtained from representative product samples, and are subject to normal manufacturing variances. Contents and logo are property of PermaTherm, Inc. All rights reserved. Copyright 2008 ? EPS-PP-0508