ES3 Commercial Presentation

- 4. - CERTIFICATES ŌĆó ISO 9001: 2000 ŌĆó API Spec. 5L and 5LX ŌĆó API Spec. 2B for Fabricated Steel Pipes ŌĆó ASME Stamps U, U2, S ŌĆó ISO 14001 ŌĆó ISO 18001 ŌĆó Petrobras CRCC ŌĆó Eletronuclear Supplier Cert. ŌĆó Social Stamp SA 8000

- 6. EBSE ŌĆō SHAW JOINT VENTURE

- 7. FORTUNE 500 Founded in 1987, The Shaw Group provides premier engineering, design, construction, maintenance, fabrication, and manufacturing services to private-sector and government clients in the energy, chemicals, power, nuclear, environmental, infrastructure, and emergency response markets. Name: The Shaw Group Inc. Headquarters: Baton Rouge, Louisiana Public corporation: NYSE Symbol: SHAW 2010 Revenue: $7.1 Billion USD Backlog: $20.3 Billion Number of employees: 28,000 Website www.shawgrp.com 7

- 8. GLOBAL PRESENCE 139 U.S. Locations 33 International Locations 8

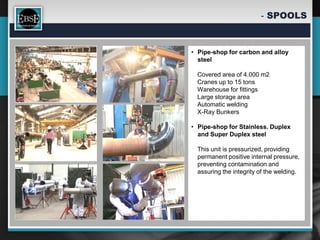

- 9. - SPOOLS ŌĆó Pipe-shop for carbon and alloy steel Covered area of 4.000 m2 Cranes up to 15 tons Warehouse for fittings Large storage area Automatic welding X-Ray Bunkers ŌĆó Pipe-shop for Stainless. Duplex and Super Duplex steel This unit is pressurized, providing permanent positive internal pressure, preventing contamination and assuring the integrity of the welding.

- 10. SPOOLS ŌĆō AUTOMATION AND HIGH PRODUCTIVITY

- 11. - SPOOLS ŌĆō COMPLEX AND LARGE DIAMETERS

- 12. - SPOOLS ŌĆō SPECIAL STEELS

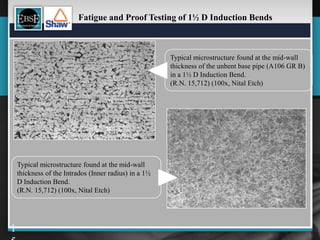

- 15. Fatigue and Proof Testing of 1┬Į D Induction Bends Typical microstructure found at the mid-wall thickness of the unbent base pipe (A106 GR B) in a 1┬Į D Induction Bend. (R.N. 15,712) (100x, Nital Etch) Typical microstructure found at the mid-wall thickness of the Intrados (Inner radius) in a 1┬Į D Induction Bend. (R.N. 15,712) (100x, Nital Etch) 1

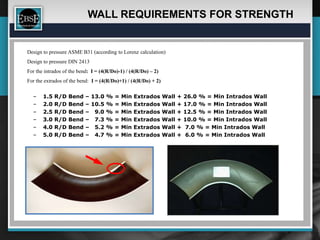

- 16. WALL REQUIREMENTS FOR STRENGTH Design to pressure ASME B31 (according to Lorenz calculation) Design to pressure DIN 2413 For the intrados of the bend: I = (4(R/Do)-1) / (4(R/Do) ŌĆō 2) For the extrados of the bend: I = (4(R/Do)+1) / (4(R/Do) + 2) ŌĆō 1.5 R/D Bend ŌĆō 13.0 % = Min Extrados Wall + 26.0 % = Min Intrados Wall ŌĆō 2.0 R/D Bend ŌĆō 10.5 % = Min Extrados Wall + 17.0 % = Min Intrados Wall ŌĆō 2.5 R/D Bend ŌĆō 9.0 % = Min Extrados Wall + 12.5 % = Min Intrados Wall ŌĆō 3.0 R/D Bend ŌĆō 7.3 % = Min Extrados Wall + 10.0 % = Min Intrados Wall ŌĆō 4.0 R/D Bend ŌĆō 5.2 % = Min Extrados Wall + 7.0 % = Min Intrados Wall ŌĆō 5.0 R/D Bend ŌĆō 4.7 % = Min Extrados Wall + 6.0 % = Min Intrados Wall

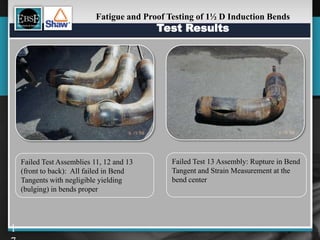

- 17. Fatigue and Proof Testing of 1┬Į D Induction Bends Test Results Failed Test Assemblies 11, 12 and 13 Failed Test 13 Assembly: Rupture in Bend (front to back): All failed in Bend Tangent and Strain Measurement at the Tangents with negligible yielding bend center (bulging) in bends proper 1

- 18. - DESTRUCTIVE TESTING

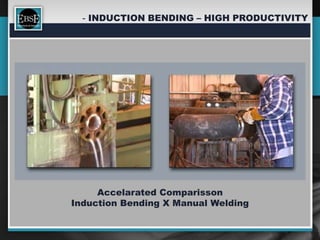

- 19. - INDUCTION BENDING ŌĆō HIGH PRODUCTIVITY Accelarated Comparisson Induction Bending X Manual Welding