Esd control-in-electronic-assembly

- 1. ESD Control In ElectronicAssemblyTom WatkinsPresidentTransforming Technologies

- 2. OutlineGeneration of Static Charge

- 3. Effects of Static Charge

- 7. Elements of ESD Control

- 8. Ionization

- 10. SummaryGeneration of Static Charge

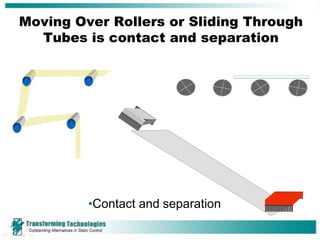

- 11. Static Charge from Contact and Separation of Dissimilar ObjectsOne Object is Positively Charged and the Other is Negatively ChargedContact and Separation is the RecipeMoving Over Rollers or Sliding Through Tubes is contact and separationContact andseparationWet Cleaning – a Major Process

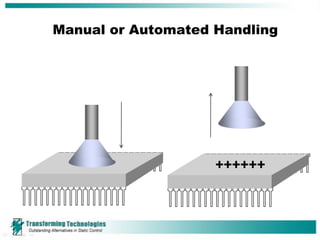

- 12. Manual or Automated Handling++++++++++++

- 13. Sources of TribochargingContact and Separation of Dissimilar MaterialsProduct handlingTweezersRobotsRollersSuction cupsParts on reelWet ProcessesWipe DownPersonnelIn chairsOn floorAgainst wallsProduct StorageIn/Out of carriersMoving across work surfacesPlasticsPacking materialPlastic Sheet protectors

- 14. LatexHuman HandsQuartz NylonAluminumChromeSteelPolyurethanePolyethylenePolypropylenePVC (Vinyl)PolycarbonateMylarTeflonPositive+Negative-Triboelectric ChargingCharge generation:The Materials Used Encourage Transfer:Triboelectric Charging

- 15. Problems Related to Static ChargeElectrostatics andPhysical Damage

- 16. Fields from Static Charge Cause Micro Electronics to Spark and Die

- 17. Damage Can Happen Several WaysCharged operator contacts part (called HBM)Charged part contacts ground (Called CDM)`Charged object (tool) contacts part (Called MM)`

- 18. Understanding the Three Models

- 20. Static Charge is a Contamination IssueCharged surfaces attract contamination strongly

- 21. Contaminated Contacts Makes Testing Unreliable

- 23. Unexpected stopESD Radiates High Frequency EMIAutomated ToolMicroprocessorOccasional Tool Issues more more difficult to diagnose than continuous issues Elements of anESD Control Program

- 24. What Must be Neutral?The Product must be kept NeutralThe environment must Also be kept neutral!What are the Major Steps to Achieve This?Ground Conductors whenever possible

- 25. Avoid Insulators whenever possibleAn ESD Control Program Eliminate Static Charge from All Surfaces Near ProductStep 1 Ground conductors – this includes workers: wrist straps, ESD shoes, ESD Chairs ESD garmentsStep 2 Eliminate insulators wherever possible: plastics are the worst offenderStep 3 – what about remaining insulators and ungrounded conductors?

- 26. Ionizers Neutralize Static Charge on Insulators & Isolated Conductors--+--+-+++--+Air Ions+--++-+----++-+--++++++++ - - - - - - - - - - - - Charged InsulatorAir Ions travel to the charged object , contact it and neutralize it.

- 27. Nothing else neutralizes insulators or isolated conductorsStatic-Safe WorkstationGrounded ShelvesESDC WristStrapBalancedESDC ChairsIonizerESDC Containers& CartsTested AC& GroundESDC WorksurfaceCircuitESD Work StationCommonPointGround (CPG)ESD Controlled Floor

- 28. Ionization

- 29. 5-20 kV Intense Electric FieldA Basic Corona IonizerPositive HV makes Positive Ions

- 30. Negative HV makes Negative IonsAlpha TechnologySealed sourcePerfectly balanced for the most sensitive devicesNo electrical power requiredNo maintenance for 1 yearInherently safeIon cloud created by alphas~1”Place target close (just beyond 1”)Or use a blower to deliver ions

- 31. Most Ionizers Use a Fan to Blow Ions to the Target Object(s)One parameter of an ionizer is the amount of air flowDC vs AC Technology+HV-HVDCACHVRequires slightly more air flow

- 32. Used in most assembly applications

- 33. Requires no balance adjustment

- 34. Cleaning required only infrequently

- 36. Separating points minimizes recombination

- 37. Used in ultra clean applications

- 38. Requires periodic adjustment of balance

- 40. More expensiveTypes of AC Ionizers From Transforming TechnologiesHVInputConventional ACPiezoelectric AC68 KHz OscillatorPiezoelectric “Transformer”

- 41. AC Technology Inherently balanced requiring NO adjustmentInfrequent cleaning requirements compared to DC technologyTransforming Technology’s ionizers have quick release grids or built in cleaner to minimize the time to clean an ionizer

- 44. High frequency virtually eliminates any swing

- 45. Use to 6” from product

- 46. Removable grilles for easy cleaning

- 47. Conventional AC

- 48. Transformer weight requires stiffer mounting bracket

- 50. Use to 12” from product

- 51. Built in cleaning tool

- 52. Both offer exceptionally low maintenance, high reliability and automatic voltage balanceMaintaining The IonizersIonizer is cleaned by turning a knobUnscrew grille to clean emitter pointsGrill pops off with no tools for point cleaningConventional IonizersBFN-Series AC IonizersIN-Series Piezo Ionizers

- 53. These Bench Top Blowers Work Well inWorkstationsInspection stations and microscopesAutomated process stepsTester stations and Probe stations

- 54. Overhead Blowers Have Many AdvantagesCovers Volume or large Area

- 55. Eliminates Dry Eyes – operators prefer overheads!

- 56. Not blocked by Obstacles on the Work Surface

- 57. BFN AC Ionizer includes cleaning knob and illumination lightsAvailable as 2 fan and 3 fan units

- 58. IN Series Piezo Ionizer includes Available as A 2 fan unit. Snap-off grills for easy cleaning

- 59. Exceptionally light for easy mountingBlow Off Gun to Clean and Discharge a SurfaceBlow away stubborn contaminants by discharging them firstErgonomic shapoe for easy useExtremely fast dischargeIntegral power and air cableExtremely loing time between cleaningsInherently balanced/. No adjustment required

- 60. Ionization in Manual AssemblyOverhead Ionizing BlowerWide Area Coverage

- 61. Fast Discharge Time

- 62. Does not blow in operator’s eyesAir NozzlesGas Useful in Confined SpacesDistance to Product: 5-50 cmDischarge time: 0.5-20 sec typicalNozzles can use interchangeable tips such as manifold, or bendable to deliver then ionization to the exact location required

- 63. Unique Air Nozzle Ionizer for Directed FlowDelivers the ions to a precise locationIdeal for manual assembly of small subassembliesFoot switch for hands free operationIN4000

- 65. Ionizers Require Cleaning and Some Also Require Adjustment

- 66. SummaryContact and SeparationIt’s the InsulatorsChoice of dissipative and conducting materialsGroundingIonizersPersonnel issuesApparel

- 70. Modern High Tech Products Are Extremely Sensitive To ESD

- 71. ConclusionStatic charge is a normal consequence of any component handling process. The ESD hazard to ICs continues to increase as devices become more complexGrounding and ionization are the static control methods employed to eliminate static chargeIonizer maintenance is an important issue and must be considered when selecting an ionizer. Customers now require control of static charge levels to 100 volts or less.