Expert Problem Solving: Using Logic Trees for Root Cause Analysis

- 1. Copyright ┬® Leanmap Expert Problem Solving Root Cause Analysis with Logic Trees Introduction

- 2. Faults and Failures in the Office Copyright ┬® Leanmap Out of paper Document error Pending decision Application frozen Orders awaiting processing Supply shortage Ownership undefined Network lost Database outdated Staff absent Excess items Backlog Process unclear

- 3. Faults and Failures in the Factory Copyright ┬® Leanmap Abnormality undetected Humidity exceeds limit Process failure Excess materials Quality rejects Program error Package jammed Wrong item loaded Operator unqualified Machine down, awaiting repair Instructions missing

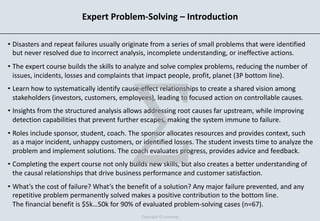

- 4. Expert Problem-Solving ŌĆō Introduction ŌĆó Disasters and repeat failures usually originate from a series of small problems that were identified but never resolved due to incorrect analysis, incomplete understanding, or ineffective actions. ŌĆó The expert course builds the skills to analyze and solve complex problems, reducing the number of issues, incidents, losses and complaints that impact people, profit, planet (3P bottom line). ŌĆó Learn how to systematically identify cause-effect relationships to create a shared vision among stakeholders (investors, customers, employees), leading to focused action on controllable causes. ŌĆó Insights from the structured analysis allows addressing root causes far upstream, while improving detection capabilities that prevent further escapes, making the system immune to failure. ŌĆó Roles include sponsor, student, coach. The sponsor allocates resources and provides context, such as a major incident, unhappy customers, or identified losses. The student invests time to analyze the problem and implement solutions. The coach evaluates progress, provides advice and feedback. ŌĆó Completing the expert course not only builds new skills, but also creates a better understanding of the causal relationships that drive business performance and customer satisfaction. ŌĆó WhatŌĆÖs the cost of failure? WhatŌĆÖs the benefit of a solution? Any major failure prevented, and any repetitive problem permanently solved makes a positive contribution to the bottom line. The financial benefit is $5kŌĆ”50k for 90% of evaluated problem-solving cases (n=67). Copyright ┬® Leanmap

- 5. The 8 Factors Placing blame or shifting the problem to an external party Owning the process until defined goals are truly achieved Trying to solve complex problems with simple tools: 5-why Solving complex problems using appropriate tools: logic tree Stopping too soon, before uncovering the underlying causes Stopping only at a desired, uncontrollable, or root cause Believing there is just one mythical cause that explains it all Accepting an infinite set of causes for any given problem Categorizing causes or picking them from a menu of causes Accepting each problem is unique, not taking shortcuts Using non-actionable causes, ŌĆ£insufficientŌĆØ or ŌĆ£inadequateŌĆØ Overcoming our own ignorance by investigating further Having different opinions or solutions for the same problem Creating a single reality that all stakeholders agree with Telling stories, starting from past, ending with the problem Identifying causal relationships, from problem to its causes Copyright ┬® Leanmap SuccessFailure

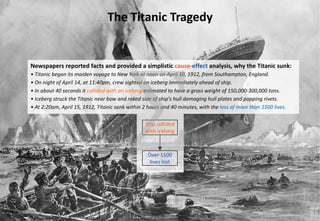

- 6. The Titanic Tragedy Copyright ┬® Leanmap Newspapers reported facts and provided a simplistic cause-effect analysis, why the Titanic sunk: ŌĆó Titanic began its maiden voyage to New York at noon on April 10, 1912, from Southampton, England. ŌĆó On night of April 14, at 11:40pm, crew sighted an iceberg immediately ahead of ship. ŌĆó In about 40 seconds it collided with an iceberg estimated to have a gross weight of 150,000-300,000 tons. ŌĆó Iceberg struck the Titanic near bow and raked side of ship's hull damaging hull plates and popping rivets. ŌĆó At 2:20am, April 15, 1912, Titanic sank within 2 hours and 40 minutes, with the loss of more than 1500 lives. Ship collided with iceberg Over 1500 lives lost

- 7. Copyright ┬® Leanmap 1500 Lives lost People in water Ship sinks Bulkheads not sealed Ship hit iceberg High speed 18 knots Small rudder size See iceberg late Bulkheads stop flooding Prioritize comfort . over safety ! Ō£ō Water fills entire hull Ship in water Cut hull open Ō£ō Insufficient lifeboat drills Prioritize leisure . over safety ! ? Speed record expected Prioritize speed over safety ? Ō£ō North Atlantic is fastest route Select fasted route Ō£ō Short sight at night Lookout not using binoculars ! Ō£ō Speed record expected Prioritize speed over safety ? Ō£ō Capability of ship Decision to go full speed Ō£ō Low turbulence from small size Design rudder to speed Ō£ō Ō£ō Insufficient lifeboats Transporting passengers Fill boats only at half capacity Ō£ō Risk analysis not performed Decide based on assumption ? ! Advances in technology Belief of unsinkable Reduce lifeboat requirements Ō£ō ? Steel plates buckled Fail to validate High slug concentration ! ? Rivets join steel plates Rivets brittle fracture Ō£ō Low temperature Low steel quality Apply high stress Ō£ō Ō£ō North Atlantic current Decide to enter ice field Ō£ō Iceberg present Ship crossing Atlantic Maneuver ineffective Ō£ō Lax maritime regulations Prioritize open view over safety ! Titanic Reality Tree Action Cause Condition Cause Desired or uncontrollable ŌåÆ Stop Need more information ŌåÆ Check Identified Root Cause ŌåÆ Act Ō£ō ? ! Download: leanmap.com/shop

- 8. Conditions + Action = Effect Copyright ┬® Leanmap Matches Available Strike Match Open Flame Oxygen Present ActionCondition Condition Effect

- 9. Conditions + Action = Effect Copyright ┬® Leanmap Paint + Canvas = Art+ Painting

- 10. The 11 Foot Bridge Copyright J├╝rgen Henn ŌĆō 11foot8.com ŌĆō used with permission Ignore Sign Crash Truck Low Bridge Durham, North Carolina, USA

- 11. Solving Complex Problems Event-Based Problems ŌĆó Disaster ŌĆó Accident ŌĆó Breakdown ŌĆó Risks ŌĆó Delays ŌĆó Defects Copyright ┬® Leanmap Rule-Based Problems Human Failures ŌĆó Errors ŌĆó Mistakes ŌĆó Violations

- 12. The 3 Types of Causes Copyright ┬® Leanmap Physical Causes ŌĆō What? Technical Reason for Failure 1 Human Causes ŌĆō How? Non-Performance or Non-Compliance 2 Latent Causes ŌĆō Why? Deficiency in Management System 3

- 13. 0.74% Patients Receive Incorrect Insulin Dose Copyright ┬® Leanmap Insulin Dose Incorrect p = 0.00741 Problem Programming Failure p = 0.01 Verification Step Skipped p = 0.4 No Backup Power Used p = 0.8 AND x Human Causes ŌĆō How? Incorrect Sugar Level Measured p = 0.00281 Correct Dose at Wrong Time p = 0.00408 Delivery System Failure p = 0.00052 Sensor Failure p = 0.002 Computation Error p = 0.00001 Timing Failure p = 0.004 Timer Reset p = 0.00008 Incorrect Insulin Computation p = 0.00011 Incorrect Pump Signal p = 0.00007 Pump Failure p = 0.00034 Power Outage p = 0.0001 OR + OR + OR + OR + AND x Transmitter Failure p = 0.0008 Physical Causes ŌĆō What? Pending Investigation Untrained p = 0.5 Distracted p = 0.2 OR + Careless p = 0.1 Overconfidence p = 0.3 Untrained p = 0.1 OR + Latent Causes ŌĆō Why?

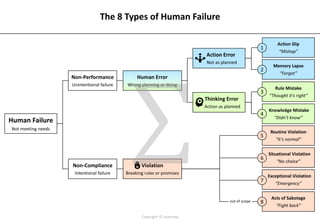

- 14. The 8 Types of Human Failure Human Failure Not meeting needs Routine Violation ŌĆ£ItŌĆÖs normalŌĆØ 5 Situational Violation ŌĆ£No choiceŌĆØ 6 Exceptional Violation ŌĆ£EmergencyŌĆØ 7 Human Error Wrong planning or doing Action Slip ŌĆ£MishapŌĆØ 1 Memory Lapse ŌĆ£ForgotŌĆØ 2 Rule Mistake ŌĆ£Thought itŌĆÖs rightŌĆØ 3 Knowledge Mistake ŌĆ£DidnŌĆÖt knowŌĆØ 4 Acts of Sabotage ŌĆ£Fight backŌĆØ 8out of scope Action Error Not as planned Non-Performance Unintentional failure Non-Compliance Intentional failure Violation Breaking rules or promises Thinking Error Action as planned Copyright ┬® Leanmap

- 15. Solving Complex Problems Copyright ┬® Leanmap 1. Problem 2. Analysis 3. Evidence 4. Causes 5. Solutions 1. Understand causal relationships 2. Identify controllable causes 3. Implement effective solutions

- 16. 1. Complete the Course 2. Apply Your Knowledge 3. Earn Your Certificate leanmap.com/academy Copyright ┬® Leanmap