Fault alerting and maximum demand controller for industries

- 1. FAULT ALERTING AND MAXIMUM DEMAND CONTROLLER FOR INDUSTRIES ABSTRACT In this fast forwarded world we are trying to reduce the manpower and trying to automate all the systems to improve the speed and also the accuracy. Here is an excellent means of automation, where we are trying to measure the parameters such as temperature, object identifier, and light intensity etc. For example, different parameters are not only measured but also a message is announced through loud speaker when there is a fault. The different sensors are placed in different zones in an industry or it can be any place where you are interested to measure and maintain the parameters. The sensed parameters are applied to the controller through transistor logic where we can monitor all the parameters. The monitored parameters are compared with the threshold values and the required controlling done through the controller. Whenever the values of the given parameters are exceeded when compared to the threshold level then the concerned parameter value is high (suppose, if the temperature is exceed to 50 degrees, which is a threshold value. Then the message, “temperature is high” delivered through the loud speaker) message is delivered through the loud speaker.

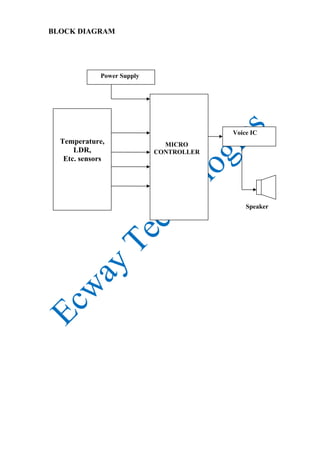

- 2. BLOCK DIAGRAM Power Supply Voice IC Temperature, LDR, Etc. sensors MICRO CONTROLLER Speaker