Field tests on cement- how and why.

- 2. Q UI Z TI ME W WW.CIVILINSIDE R.CO M

- 3. Introduction W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS

- 4. WHY TO TEST CEMENT ON SITE? W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS

- 5. 1 | CO LO UR 5 | F LO AT T E ST 7 | S T RE NGTH T E ST 3 | S M O O T HNE SS T E S T2 | LUM P T E ST 6 | S E T T ING T E S T W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS 4 | T E M P E RATURE T E ST 8 | S M E LL T E S T

- 6. CI VI L I NSI DER T E T S 1 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Open the bag of cement and take a look at the cement Check the colour of cement. 1 2 3 Cement should be greenish grey and it should be uniform in colour throughout.

- 7. CI VI L I NSI DER T E T S 2 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Look at cement for visible lumps. There should not be any visible lumps. Put hand into the cement bag 1 2 3 Any bags contains such lumps, should be rejected and returned back to the supplier. There should not be any lumps inside. 3

- 8. CI VI L I NSI DER T E T S 3 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Take a pinch of cement in hand. Rub it between the fingers. Cement should feel Smooth. 1 2 3 Lump test and smoothness test are somewhat the same. In smoothness test we seek for very small hard particles that are left during grinding. If cement feels rough then it is bad quality cement. 3

- 9. CI VI L I NSI DER T E T S 4 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Put your hand into cement. Feel the temperature. A cool feeling Indicates good quality of cement. 1 2 3 If hand is poured inside the bag full of Cement it should feel cold inside. If the cement feels somewhat warm then it indicates the start of hydration of cement due to absorption of moisture. A warm feeling indicates hydration of cement. 3

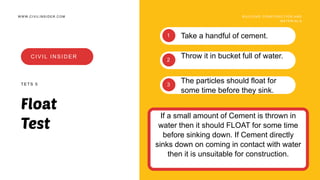

- 10. CI VI L I NSI DER T E T S 5 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Take a handful of cement. Throw it in bucket full of water. The particles should float for some time before they sink. 1 2 3 If a small amount of Cement is thrown in water then it should FLOAT for some time before sinking down. If Cement directly sinks down on coming in contact with water then it is unsuitable for construction.

- 11. CI VI L I NSI DER T E T S 6 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Make a thick paste of cement with water. Apply it on a piece of a glass plate. And keep it underwater for 24 hours. If hand is poured inside the bag full of Cement it should feel cold inside. If the cement feels somewhat warm then it indicates the start of hydration of cement due to absorption of moisture. After 24 hours cement paste should set and not crack.

- 12. CI VI L I NSI DER T E T S 7 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS Prepare a block of cement Of dimension 25 mm ├Ś25 mm and length of 200 mm. Immersed it for 7 days in water. Then after 7 days place it on supports 150mm apart. And load it with a weight of about 34kg. If the block doesnŌĆÖt show any failure, then the cement is of good quality.

- 13. CI VI L I NSI DER T E T S 8 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS If the cement contains too much- pounded clay and silt as an adulterant, the paste will give an earthy smell.

- 14. CI VI L I NSI DER T E T S 9 W WW.CIVILINSIDE R.CO M B UI L DING CO NS TRUCTIO N A ND MATE RI A LS The strength of cement reduces with time, so it is important to check the manufacturing date of the cement. Generally, cement should be used before 90 days from the date of manufacturing.

- 17. SUBSCRIBE!