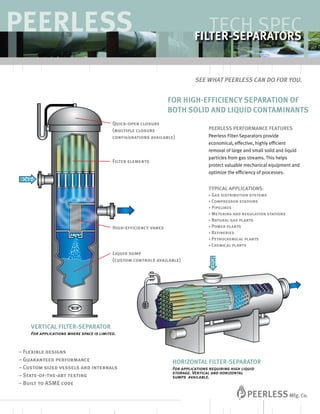

Filter separator brochure

- 1. FOR HIGH-EFFICIENCY SEPARATION OF BOTH SOLID AND LIQUID CONTAMINANTS PEERLESS PERFORMANCE FEATURES Peerless Filter-Separators provide economical, effective, highly efficient removal of large and small solid and liquid particles from gas streams. This helps protect valuable mechanical equipment and optimize the efficiency of processes. TYPICAL APPLICATIONS: ? Gas distribution systems ? Compressor stations ? Pipelines ? Metering and regulation stations ? Natural gas plants ? Power plants ? Refineries ? Petrochemical plants ? Chemical plants Quick-open closure (multiple closure configurations available) Filter elements High-efficiency vanes Liquid sump (custom controls available) Peerless See what Peerless can do for you. TECH SPEC FILTER-SEPARATORS HORIZONTAL FILTER-SEPARATOR For applications requiring high liquid storage. Vertical and horizontal sumps available. VERTICAL FILTER-SEPARATOR For applications where space is limited. ®C Flexible designs ®C Guaranteed performance ®C Custom sized vessels and internals ®C State-of-the-art testing ®C Built to ASME code

- 2. PRINCIPLE OF OPERATION (A) Incoming flow with entrained solids and liquids pass outside-in through the filter media where solids are removed and coalescing takes place. Bulk liquids are also removed in this first stage. (B) The gas then carries the coalesced liquids through the standpipe/tubesheet. (C) Remaining liquids are directed to the high- efficiency vane mist extractor. (D) Liquids from the vane mist extractor are collected away from the gas stream. VANE MIST EXTRACTORS Peerless Vanes come in more than a dozen high-performance profiles. Extensive Peerless engineering and testing has shown vane spacing, pocket depth, and sizing are critical to the capacity and efficiency of vane elements. Tight control of these parameters during fabrication makes Peerless quality an integral part of our vane performance. CONFIGURATIONS Peerless Filter-Separators are available in vertical or horizontal, and single- or double- barrel configurations. Closures for access to the filter elements can be either full- or reduced- diameter, and bolted or quick- opening designs. 1FFSMFTT'JMUFS 4FQBSBUPS1FSGPSNBODF 4FQBSBUJPOGGJDJFODZ %SPQMFU4J[F ?N -JRVJE%SPQMFUT 4PMJE1BSUJDMFT Typical Peerless Vane Element Vertical Peerless Filter- Separator configuration CONSULT A PEERLESS SPECIALIST FOR YOUR SEPARATION, RETROFIT, AND SPARES REQUIREMENTS. Efficiencies will vary with the selection of filter elements and vanes. This Peerless Filter-Separator is installed at a compressor station in natural gas transmission service. This Peerless unit is designed with a cost-effective full-diameter closure. PERFORMANCE GUARANTEE Peerless Filter-Separators are guaranteed to remove 100% of all liquid droplets 8 microns and larger and remove 99.5% of those 0.5 to 8 microns in size. The minimum guaranteed solid particle removal is 100% of 1 micron and larger and 99.5% for those 0.5 to 1 micron in size. Peerless Mfg. Co. 14651 North Dallas Pkwy. Suite 500 Dallas, TX 75254 Phone 214-357-6181 www.peerlessmfg.com NASDAQ Symbol: PMFG Peerless Mfg. Co. Regional Office 35 Jalan Pemimpin, #07-02 Singapore 577176 Phone 011-65-6354-2306 Peerless Europe Limited Cardinal°Øs Court, Bradford St. Braintree, Essex CM7 9AT United Kingdom Phone 011-44-1376-556030 Making Energy SAFE, EFFICIENT, AND CLEAN. B C D A