Flip bottle presentation

- 1. FLIP Bottle? Presentation Prepared by: Vincent M. Allora c/o Silent Dynamite, LLC. d.b.a. FLIP Bottle? U.S. Patent 6,398,050 904 Park Avenue Unit 530188 Lake Park, Florida 33403 USA Phone: 954-214-2567 Fax: 954-337-0777 Email: vin@FlipBottle.com

- 2. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 2 of 15 Table of Contents 1 Project Background ....................................................................... 3 2 Project Objective............................................................................ 3 3 Final Files...................................................................................... 4 Appendix A: Shelf Life Analysis ......................................................... 12

- 3. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 3 of 15 R&D/Leverage is a global integrated design and manufacturing firm focused on creating novel brand-relevant and consumer- driven structural designs and bringing them to life through prototyping, unit tooling, and commercial mold manufacturing. Our integrated idea to implement process drives your project from concept to business case to manufacturing and ultimately to market faster and more successfully because this integrated process eliminates the hand-offs found in the traditional functional silos of the product development process. Project Background Silent Dynamite has spent the last couple of years developing a unique single-serve wine package, the Flip Bottle, and is now interested in bringing this concept to market. The Flip Bottle is unique in that it is both a bottle and a glass, allowing the consumer to use the package as either a normal 187mL bottle of wine with a standard 25H18 ROPP closure, or flipping the bottle over and removing the cap in order to use the bottle as the wine glass. The first phases of design and engineering work have been completed by Silent Dynamite with other partners. This work is now ready to move to the final stages of engineering and development with R&D/Leverage. Project Objective The objective of this project is to produce prototypes of the Flip Bottle as well as to build the unit tools for the bottle and cap in order to produce real samples out of real materials. The initial stages of R&D Leverage¡¯s involvement will be to finalize the cosmetic look to the package while ensuring the geometry produced will be able to be manufactured by an injection molding process. Once the final geometry has been achieved, high quality prototypes will be produced for final approval. At that point, unit tool will be built to produce samples of the bottle and base out of the chosen production materials completing the development phase of this project.

- 4. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 4 of 15 An exploded view shows the metal cap, the injection molded clear PET bottle, the foil seal and the injection molded base. As can be seen, the base can be molded in any color.

- 5. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 5 of 15 The bottle has been designed to be made by an injection molding process. The base material will be polyethylene terephthalate (PET) which will provide excellent clarity and when coupled with an oxygen scavenger the necessary shelf life for a single serve wine package (see attached ¡°Shelf Life Analysis¡±).

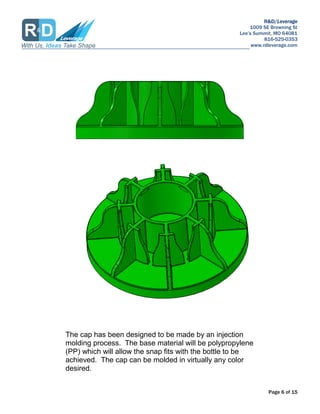

- 6. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 6 of 15 The cap has been designed to be made by an injection molding process. The base material will be polypropylene (PP) which will allow the snap fits with the bottle to be achieved. The cap can be molded in virtually any color desired.

- 7. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 7 of 15

- 8. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 8 of 15

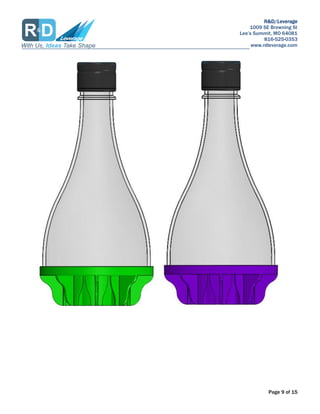

- 9. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 9 of 15

- 10. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 10 of 15 The Yin Yang effect produced when the bottles are side by side produces unique packaging potential.

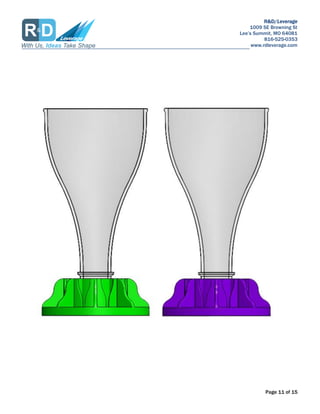

- 11. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 11 of 15

- 12. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 12 of 15 Appendix A

- 13. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 13 of 15 April 14, 2015 Project: Flip Bottle Shelf Life Analysis Customer: Vincent Allora of Silent Dynamite, LLC. Reference: R&D/Leverage job #82983 Calculations By: Mark Rule of Container Science Objective: The objective of this shelf life analysis is to determine additive amount and type needed to achieve a 2 year shelf life of a PET injection molded Flip Bottle. Shelf life is determined by the amount of oxygen ingress into the package over time. Since wine is a sensitive beverage, 1ppm (parts per million) is the industry standard for the maximum amount of oxygen allowed to ingress over time. Product Test: Details of the product tested can be seen in the attached file. A standard injection molding grade PET was used for the simulation. Since molded PET is permeable to oxygen, it does not pass shelf life tests alone. Chemicals called oxygen scavengers are added to the resin pellets before they are molded into shape. This simulation evaluated the shelf life of virgin PET, PET with .5% Oxyclear, 1% Oxyclear, and 1% Amosorb. The environmental conditions used for the simulations were a temperature of 22¡ãC with a relative humidity of 50%. The bottle was tested with standard impermeable closures at both ends. Conclusion: All three simulations ran with the inclusion of an oxygen scavenger passed the 2 year long shelf life test. The simulation ran without the oxygen scavenger failed the maximum allowable oxygen ingress after only 20 days. Due to the part geometry and inherent material properties, an acceptable shelf life can be achieved with this package with minimal additives. Results: The analysis is based on predicting the two year amount of oxygen content ingression with the specified container. The data shown below graphs oxygen content in ppm versus time in days. It should be noted that the spikes in the graphs for the simulations using oxygen scavengers can be attributed to the oxygen initially migrating out of the bottle sidewall. The model equilibrates oxygen with the sidewall prior to filling (with concurrent scavenging). Once the bottle is filled, the oxygen gets rapidly reabsorbed and reacts with the scavenger, hence the quick drop-ff.

- 14. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 14 of 15 The chart below shows the predicted oxygen ingression of the bottle without an oxygen scavenger. As can be seen, the oxygen ingress exceeds the allowable 1ppm after only approximately 20 days. The chart below shows the predicted oxygen ingression of the bottle with .5% Oxyclear. As can be seen, the oxygen ingress does not exceed the allowable amount after the simulated 730 days.

- 15. R&D/Leverage 1009 SE Browning St Lee¡¯s Summit, MO 64081 816-525-0353 www.rdleverage.com Page 15 of 15 The chart below shows the predicted oxygen ingression of the bottle with 1% Oxyclear. As can be seen, the oxygen ingress does not exceed the allowable amount after the simulated 730 days. The chart below shows the predicted oxygen ingression of the bottle with 1% Amosorb. As can be seen, the oxygen ingress does not exceed the allowable amount after the simulated 730 days.