Flixible Pavement Layers

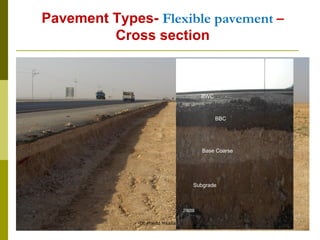

- 1. Pavement Types- Flexible pavement – Cross section Dr.Majed Msallam 33 Subgrade Base Coarse BBC BWC

- 2. Flexible Pavement Types 1- Conventional Flexible Pavement. ‫الرصفة‬ ‫التقليدية‬ ‫اإلسفلتية‬ ‫من‬ ‫النوع‬ ‫هذا‬ ‫الرصفة‬ ً‫مهندس‬ ‫جمعٌة‬ ‫طورته‬ ‫األمرٌكٌة‬ ‫والمواصالت‬ ‫الطرق‬ AASHTO ‫تتكون‬ ‫حٌث‬ ‫الرصفة‬ ‫رئٌسٌة‬ ‫طبقات‬ ‫ثالث‬ ‫من‬ ‫على‬ ‫القدرة‬ ‫حٌث‬ ‫من‬ ‫مواد‬ ‫نوعٌة‬ ‫أفضل‬ ‫وتكون‬ ‫أو‬ ‫السطح‬ ‫طبقة‬ ‫وتسمى‬ ‫العلٌا‬ ‫الطبقة‬ ً‫ف‬ ‫التحمل‬ ‫اإلسفلتٌة‬ ‫الطبقة‬ SURFACE COURSE ‫األساس‬ ‫طبقة‬ ‫تلٌها‬ BASE COURSE ‫ثم‬ ‫األساس‬ ‫تحت‬ ‫ما‬ ‫طبقة‬ SUBBASE COURSE ‫هذه‬ ‫خالل‬ ‫من‬ ‫المرورٌة‬ ‫الحموالت‬ ‫تأثٌر‬ ‫نقل‬ ‫وٌتم‬ ‫قدرتها‬ ‫تكون‬ ‫أن‬ ‫ٌفترض‬ ً‫الت‬ ‫التربة‬ ‫إلى‬ ‫الطبقات‬ ‫ٌجري‬ ‫ما‬ ‫وغالبا‬ ‫نسبٌا‬ ‫عالٌة‬ ‫التحمل‬ ‫على‬ ‫دمكها‬ COMPACTED SUBGRADE ‫مواصفاتها‬ ‫لتحسٌن‬ . Dr.Majed Msallam 37

- 3. Conventional Flexible Pavement  Are layered systems with:  better materials on top where the intensity of stress is high and  inferior materials at the bottom where the intensity is low.  A structure that;  maintains intimate contact with sub grade and  distribute loads to sub grade , and depends on  aggregate interlock,  particle friction, and  cohesion for stability.  Adherence to this design principle makes the use of local materials possible and usually result in the most economical design. Dr.Majed Msallam 38

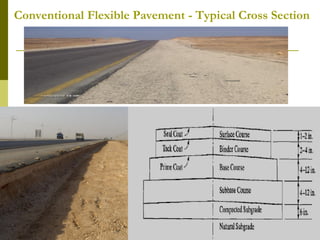

- 4. Conventional Flexible Pavement Cross section consist  Cross section consist of (from top): 1. Seal coat 2. Surface course 3. Tack coat 4. Binder course 5. Prime course 6. Base course 7. Sub base course 8. Compacted sub grade 9. Natural sub grade  The use of various courses is based on either necessity or economy, and some of the courses may be omitted. Dr.Majed Msallam 39

- 5. Conventional Flexible Pavement - Typical Cross Section Dr.Majed Msallam 40

- 6. Seal Coat  Seal coat: Thin asphalt surface treatment used to: 1- Waterproof or seal the surface. 2- Rejuvenate or revitalize old bituminous wearing surfaces. 3- To nonskid slippery surfaces. 4- Improve night visibility.  Single Surface treatment = single application of bituminous material that is covered by a light spreading of fine aggregate or sand (spread mechanically) then compacted with pneumatic tired rollers. Dr.Majed Msallam 41

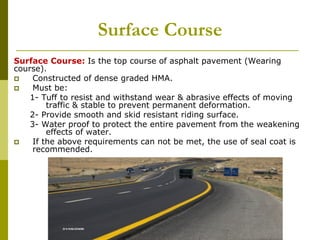

- 8. Surface Course Surface Course: Is the top course of asphalt pavement (Wearing course).  Constructed of dense graded HMA.  Must be: 1- Tuff to resist and withstand wear & abrasive effects of moving traffic & stable to prevent permanent deformation. 2- Provide smooth and skid resistant riding surface. 3- Water proof to protect the entire pavement from the weakening effects of water.  If the above requirements can not be met, the use of seal coat is recommended. Dr.Majed Msallam 43

- 9. Dr.Majed Msallam 44 Surface Course

- 10. Binder Course  Binder course (known also as Asphalt base course) is the asphalt layer beneath the surface course.  Reasons for use: 1- HMA is too thick to be compacted in one layer (if the binder course is more than 3” it is placed in two layers). 2- More economical design, since binder course generally consist of larger aggregates and less asphalt and doesn’t require high quality. Dr.Majed Msallam 45

- 11. Tack & Prime Coats  Tack coat (RC): Very light application of asphalt (emulsion) to ensure a bond between the surface being paved and the overlying course.  Binds asphalt layer to PCC base or to an old asphalt pavement. Dr.Majed Msallam 46

- 12. Tack & Prime Coats  Prime coat: Application of low viscosity Cutback asphalt to an absorbent surface such as untreated granular base on which asphalt layer will be placed on. • It binds the granular base to the asphalt layer. Dr.Majed Msallam 47

- 13. Tack & Prime Coats  Tack coat doesn’t require the penetration of asphalt into the underlying layer, while  prime coats penetrates into the underlying layer, plugs the voids , and form a watertight surface.  Both are spray application. Dr.Majed Msallam 48

- 14. Base & Sub Base Courses  Base course: Layer immediately beneath the surface or binder course.  Composed of crushed stone, crushed slag, or other untreated or stabilized materials.  Has good stability & density  Distributes & spreads the stresses created by wheel loads so that the stresses transmitted to the sub grade will not be great to result in excessive deformation or displacement of that foundation. Dr.Majed Msallam 49

- 15. Sub base Course  Sub base course: Layer beneath the base course, used mostly for economy purposes since it can be of lower quality.  Sub bases may be used in areas where: 1- frost action is sever, or 2- Sub grade soil is extremely weak, or 3- Where construction working table is needed. Dr.Majed Msallam 50

- 16. Sub Base Courses Dr.Majed Msallam 51

- 17. Sub grade  Sub grade can be either in situ soil or a layer of selected materials.  The top 6” of sub grade should be scarified and compacted to the desired density near the optimum moisture content. Dr.Majed Msallam 52

- 18. Sub grade Dr.Majed Msallam 53