Flow control and measurement

- 1. FLOW CONTROL AND MEASUREMENT (FLOW VALVES AND METERS)

- 2. WHAT IS FLOW MEASUREMENT? Flow measurement can be defined as quantification of the movement of water in a given channel. Flow can be measured either by determining the displacement and/or Velocity of the water. Water meters usually control measure and display total usage in cubic meters, on either mechanical or electronic registers.

- 3. WHAT IS THE NEED OF FLOW MEASUREMENT? ŌĆó Flow measurement is integrated into every aspect of modern life, from the measurement of water flow in power plants to the metering of household water. ŌĆó Specifically, the power plant must measure correctly for safety, efficiency, and revenue, while the homeowner is interested in being charged correctly. ŌĆó Accurate flow measurement has a positive impact on energy conservation. ŌĆó It helps understand storm water volume and how much flow is passing through the treatment plant ŌĆö and this, in turn, protects the environment and helps determine water quality standards. Water treatment plant operator

- 4. Flow can be divided into two main flows which are: ŌĆó Open channel flow and ŌĆó Closed conduit flow. VALVES AND WATER METERS Flow is controlled by use of valves at intervals to either to slow down, allow faster flow or completely shut down the flow. Some water meters usually perform both the function or making readings and controlling flow while others just conduct measuring only. Water Meter Well, How much water do you use?

- 5. Garden Hose Water Meter Tracks The Amount Of Water You Use

- 6. DIFFERENT TYPES OF FLOW MEASUREMENT Controlling flow of a fluid-power system does not necessarily mean regulating volume per unit of time from a valve. Flow rate can be specified three different ways, so it is important to be aware of how flow is to be specified or measured: ŌĆó Volumetric flow rate, Qv, expressed in units of in.3/sec or min - or cc/sec or cc/min in SI metric measure - is used to calculate the linear speeds of piston rods or rotational speeds of motor shafts. ŌĆó Weight flow rate, Qw, expressed in units of lb/sec or lb/min, is used to calculate power using English units of measure. ŌĆó Mass flow rate, Qg, expressed in units of slugs/sec or slugs/min for English measure - or kg/sec or kg/min in SI metric measure - is used to calculate inertia forces during periods of acceleration and deceleration.

- 7. FLOW METERS ŌĆó A flow meter is a device used to measure the flow rate or quantity of a gas or liquid moving through a pipe. Flow measurement applications are very diverse and each situation has its own constraints and engineering requirements. A Turbine Meter 1.Positive Displacement/Volumetric - Directly measure the actual volume Eg. -Piston flow meters, Gear flow meter, Rotary Vane Meter 2.Mass -The output signal is directly related to the mass passing through the meter. Eg. ŌĆō Thermal And Coriolis Flow Meter 3.Velocity - The output signal directly related to the velocity passing through the meter. Eg. ŌĆō Electromagnetic, ultrasonic flow meters etc VARIOUS TYPES OF FLOWMETERS:

- 8. FLOW METERS IN USE The common types of flowmeters that find industrial applications can be listed as below: ŌĆó (a) Obstruction type (differential pressure or variable area) (b) Inferential (turbine type), (c) Electromagnetic, (d) Positive displacement (e) fluid dynamic (vortex shedding), (f) ultrasonic and (g) Mass flowmeter (Coriolis). VIDEO: The Differential Pressure Flow Measuring Principle (Orifice-Nozzle-Venturi) VIDEO: The Ultrasonic Flow Measuring VIDEO: The Electromagnetic Flow Measuring

- 9. CONTROL OF FLOW RATE WITH VALVES ŌĆó Flow-control valves include simple orifices to sophisticated closed-loop electrohydraulic valves that automatically adjust to variations in pressure and temperature. ŌĆó The purpose of flow control in a hydraulic system is to regulate speed and thus controlling flow rate. The main functions of Control Valves are as follows: ’ü▒ control the flow capacity ’ü▒ control the water level ’ü▒ control the pressure in case of a following pipeline. Definition, VALVE: A valve is a mechanical device that blocks a pipe either partially or completely to change the amount of fluid that passes through it.

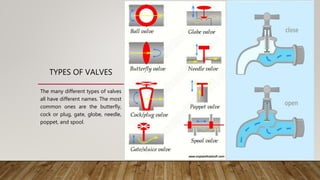

- 10. TYPES OF VALVES The many different types of valves all have different names. The most common ones are the butterfly, cock or plug, gate, globe, needle, poppet, and spool.

- 11. SUMMARY ŌĆó The measurement of flow should be simple, as it is a fundamental part of our industry(water). ŌĆó The need to automatically control with flow meters and/or measure more accurately brought about a refinement of measurement techniques that has provided greater efficiency. ŌĆó All of the technologies available are valid, and all of them have their strengths and their weaknesses. ItŌĆÖs up to the engineer to select the most appropriate technology and to ensure that it is designed and installed correctly.