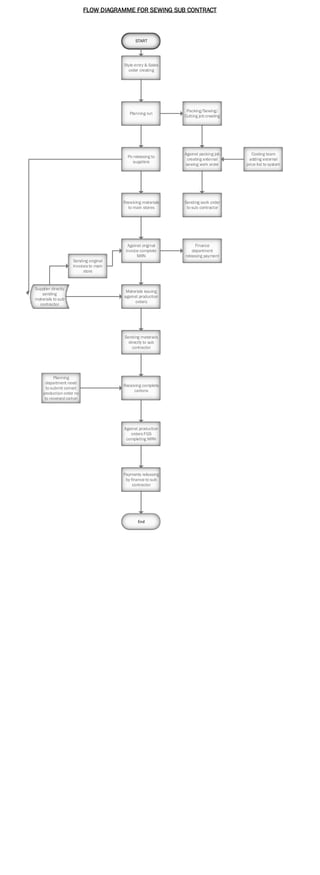

Flow diagramme for sewing sub contract

- 1. START Style entry & Sales order creating Planning run Packing/Sewing/ Cutting job creating Po releasing to suppliers Receiving materials to main stores Against original invoice complete MRN Finance department releasing payment Materials issuing against production orders Sending materials directly to sub contractor Receiving complete cartons Against production orders FGS completing MRN Payments releasing by finance to sub contractor End Against packing job creating external sewing work order Costing team adding external price list to system Sending work order to sub contractor Supplier directly sending materials to sub contractor Sending original invoices to main stors Planning department need to submit correct production order no to received carton FLOW DIAGRAMME FOR SEWING SUB CONTRACT