Fmmmppt.ppt 111

- 1. Ėý

- 2. DEPARTMENT OF MECHANICAL ENGINEERING

- 3. ADEEL HASSAN KHAN MUHAMMAD HAIDER JAFRI GHULAM AHMAD MUZAMIL ARIF

- 4. Ėý

- 5. PUMPS HOW PUMPS WORK BASIC TYPES OF PUMPS PROBLEMS OF PUMPS SOLUTIONS OF PUMP PROBLEMS SUMMARY

- 6. A pump is a mechanical device that changes mechanical power into fluid power. Pumping is the addition of energy to a fluid . Pumping action creates a partial vacuum while atmospheric pressure forces liquid up.

- 7. Ėý

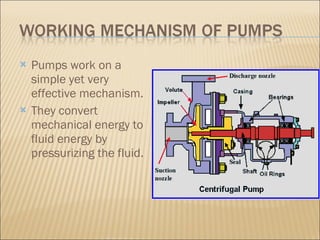

- 8. Pumps work on a simple yet very effective mechanism. They convert mechanical energy to fluid energy by pressurizing the fluid.

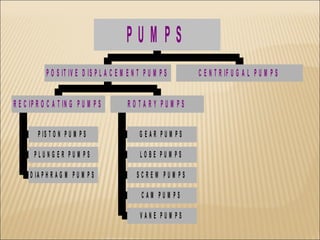

- 9. Positive Displacement Pumps Centrifugal Pumps.

- 10. Ėý

- 11. Ėý

- 12. Of a number of problems, the major pump problems are: Suction problem System problem Mechanical problem

- 13. Pump not primed Pump suction pipe not completely filled with liquid Suction lift too high Insufficient margin between suction pressure and vapor pressure Excessive amount of air or gas in the liquid Air pockets in the suction line

- 14. Air leaks into the suction line Air leaks into the pump through the stuffing box or gland Foot valve too small Foot valve partially clogged Inlet of suction pipe insufficiently submerged Water seal pipe plugged Seal cage improperly located in stuffing box, preventing sealing fluid entering space to form a seal

- 15. Speed too low Speed too high Wrong direction of rotation The total head of system higher than design pump head The total head of system lower than design pump head

- 16. Specific gravity of liquid different from design Viscosity of liquid differs from that for which the pump was designed Operation at very low capacity Parallel operation of pumps unsuitable for such operation

- 17. Foreign matter in the impeller Misalignment Foundations not rigid Shaft bent Rotating part rubbing on stationary part Bearing worn Wearing rings worn Impeller damaged Casing gasket defective, permitting internal leakage

- 18. Packing improperly installed Incorrect type of packing for operating conditions Shaft running off-center because of worn bearings or misalignment Rotor out of balance, resulting in vibration Gland too tight, resulting in no flow of liquid to lubricate the packing

- 19. Ėý

- 20. Cavitation is the formation of vapour bubbles of a flowing liquid in a region where the pressure of the liquid falls below its vapor pressure

- 21. Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings

- 22. Ėý

- 23. Better Sealing Devices Component Modification System Change New Pump Personnel Training

- 24. ****Any QuestionsâĶ!!!*** *** ***

- 25. Ėý