Forehearth Design Automation

- 1. go! out of your mind. Design Automation of Fore hearth

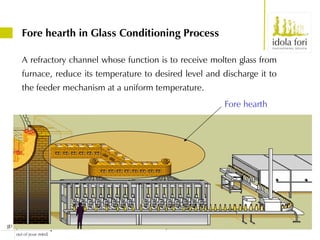

- 2. go! out of your mind. Fore hearth in Glass Conditioning Process A refractory channel whose function is to receive molten glass from furnace, reduce its temperature to desired level and discharge it to the feeder mechanism at a uniform temperature. Fore hearth

- 3. go! out of your mind. Fore Hearth Construction 1. Sub Structure Steel Assembly 2. Sub Structure Insulation Assembly 3. Channel Assembly 4. Burner Course Assembly 5. Roof Course Assembly 6. Super Structure Insulation Assembly 7. Super Structure Steel Assembly 8. Burner Piping Assembly 3 2 1 4 5 7 8

- 4. go! out of your mind. The Need ŌĆó Design to be manufactured across the globe ŌĆó Product optimization & Standardization ŌĆó To Increase the Productivity & reducing the routine work ŌĆó Knowledge capturing ŌĆó Reusing the design ŌĆó To increase the product ranges to suit the new customer requirements ŌĆó Integrating the design process with PDM

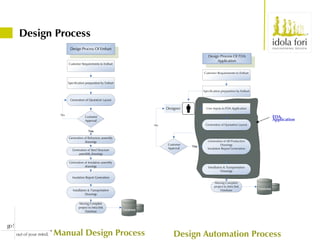

- 5. go! out of your mind. Design Process Design Automation Process Design Process Of FDA Application Customer Requirements to Emhart Specification preparation by Emhart Designer User Inputs to FDA Application Generation of Quotation Layout Customer Approval No Yes Generation of All Production Drawings Insulation Report Generation Installation & Transportation Drawings Moving Complete project to Intra link Database Database Manual Design Process FDA Application

- 6. go! out of your mind. Development Platform Software ŌĆó Pro/Engineer Wildfire 2.0 (32 bit) ŌĆó Java 1.5 ŌĆó Oracle 9i Production Hardware ŌĆó Intel Xeon processor ŌĆó RAM : 4 GB

- 7. go! out of your mind. Product Complexity ŌĆó Maintaining model history by using database (Legacy Data) ŌĆó Generating generic parametric library that supports generation of all possible configurations of fore hearth. ŌĆó Tailor making the components to satisfy the Pro/ Wind Chill conditions ŌĆó Execution of Pro/E tasks at application runtime, like.. ŌĆó Renaming of all used components ŌĆó Deletion of un used model tree objects ŌĆó Dynamic assembling based on the requirement ŌĆó Insulation assembly & report generation ŌĆó Generation of models in metric & Imperial units. ŌĆó Interdependency between components s+c.avi

- 8. go! out of your mind. Salient Features of Application ŌĆó Modular based assembly generation ŌĆó Legacy data base ŌĆó generating Input report for user validation before going for model generation. ŌĆó Even a non designer can handle the application, if he had specification sheet. ŌĆó Compliance of part numbering system to suit with Pro Wind-chill specifications. ŌĆó Generation of Quotation & Installation layouts ŌĆó Calculation of insulation material

- 9. go! out of your mind. Before Design Automation After Design Automation Projects Efforts 1056 Man Hours 4 Man Hours Duration 66 Days 1 days Quotations Efforts 120 Man Hours 4 Man Hours Duration 15 Days 1 days Design Cycle Time