Frame Materials - By Consultant Optom Nayana KT

- 1. NAYANA.K.T CONSULTANT OPTOMETRIST BSC.OPTOM FELLOWSHIP IN BSV AND ORTHOPTICS FRAME MATERIALS

- 2. Properties of an ideal frame materials ? Non- allergic ? Resistant to corrosion ? Non-flammable ? Inexpensive ? Durable ? Adjustable ? Low specific gravity ? Mechanical stability

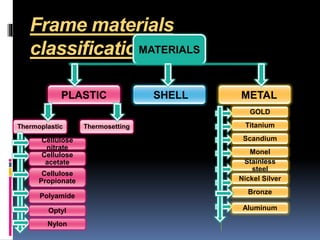

- 3. Frame materials classificationsMATERIALS PLASTIC SHELL METAL Thermoplastic Thermosetting Cellulose nitrate Cellulose acetate Cellulose Propionate Polyamide Optyl Nylon GOLD Stainless steel Monel Nickel Silver Titanium Scandium Bronze Aluminum

- 5. PLASTIC Cellulose Acetate Cellulose Propionate Made from cotton lint(cut from sheets) Made from injection mould Production ¨CTime consuming Production ¨Cfewer steps only Lighter in weight More lighter than acetate Polishes well-Improving the appearance of frame High quality frame material that takes high polish Non-flammable Non-flammable Easily repaired Can be made thinner than acetate Blister if overheated Brittle with age Allergic reaction by uncoated material Brittle with age

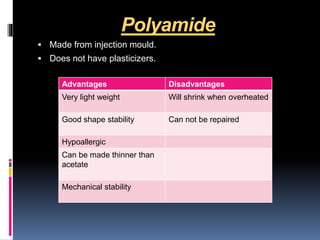

- 6. Polyamide ? Made from injection mould. ? Does not have plasticizers. Advantages Disadvantages Very light weight Will shrink when overheated Good shape stability Can not be repaired Hypoallergic Can be made thinner than acetate Mechanical stability

- 7. OPTYL ? Thermo elastic material and has a powerful memory. ADVANTAGES DISADVANTAGES Very hard Returns to its normal shape if it is over heated Durable Can not be repaired Hypo allergic Non-flammability Dimensionally stable Lighter than cellulose acetate Will not age (Due to the lack of plasticizers)

- 8. NYLON ADVANTAGES DISADVANTAGES Very strong and flexible. Very poor surface finish Light weight, comfortable Quite dull and not polished like other plastics Not affected by heat and cold Difficult to adjust and fit lenses into nylon frame. Will break if dropped. Injection moulded

- 9. Tortoise -Shell ADVANTAGES DISADVANTAGES Its quality depends upon the color of the shell which ranges from amber to dark red Poor abrasion resistance Durable Poor scratch resistance Mottling Poor impact resistance Easy to maintain Light weight

- 11. GOLD FINE GOLD SOLID GOLD GOLD FILLED GOLD PLTAED 24 karat gold 10 karat gold Gold is brazed on the surface of a base metal and become bonded Thin layer of gold is applied on the frame by the process of electrolysis Chemically pure and unalloyed metal Fine gold or gold alloyed use High quality Very less amount of gold Too soft, Durable Gold+ base metal evenly mixed Tarnish and perspiration resistant Amount of gold is very less than gold filled frame High quality Frame is solid rather than hollow Easy to adjust and align Durable and Thin Tarnish and perspiration resistant High quality Durable Easier and cheaper

- 12. TITANIUM ADVANTAGES DISADVANTAGES Light weight Expensive Flexible Very limited colors Corrosion resistant Hard to solder or weld Abration resistant Thinnest of all metals Hypoallergic

- 13. Beta- Titanium ? Titanium + other metal(Vanadium & Aluminium) ? Very Light weight ? More tensile strength ? Greater hardness ? Can be made very thin Alpha ¨Cbeta titanium ? Titanium alloy lying midway between titanium and beta-titanium in tensile strength and hardness

- 14. Scandium ? New one. ? One of the elements, lightest ¨CSG-3 (40% lighter than titanium) ? Durable ? More expensive

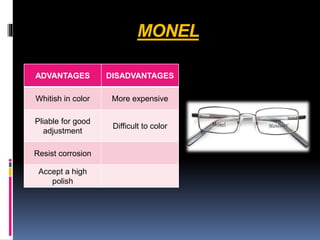

- 15. MONEL ADVANTAGES DISADVANTAGES Whitish in color More expensive Pliable for good adjustment Difficult to color Resist corrosion Accept a high polish

- 16. Stainless Steel ADVANTAGES DISADVANTAGES Durable More expensive than gold plated frame Flexible Can not be repaired Non-magnetic Resistant to oxidation and corrosion Flexibility Endless color change strong

- 17. Nickel silver or Germen Silver ? 50% Copper(Pliability) & 25% Nickel(Whitish appearance) ? Zink and other metals (Strength) ? Rigid and lustrous ? Mostly used base metal in gold

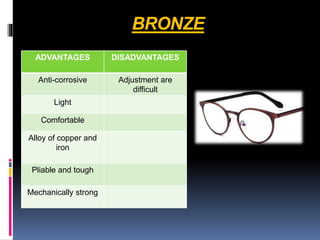

- 18. BRONZE ADVANTAGES DISADVANTAGES Anti-corrosive Adjustment are difficult Light Comfortable Alloy of copper and iron Pliable and tough Mechanically strong

- 19. ALUMINIUM ADVANTAGES DISADVANTAGE S Stain and tarnish resistant Does not solder or weld well Strong and light weight Requires screw or rivets Resistant to corrosion Conduct heat readily and become cold in winter Paintable No flexibility

- 20. THANK YOU