Fta 2013 LUX itp v1.0

- 1. In The Plate The Latest Innovation from MacDermid Printing Solutions FTA InfoFlex April 29-30, 2013

- 2. Enabling higher quality print 2

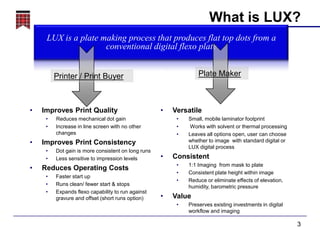

- 3. 33 What is LUX? LUX is a plate making process that produces flat top dots from a conventional digital flexo plate ŌĆó Improves Print Quality ŌĆó Reduces mechanical dot gain ŌĆó Increase in line screen with no other changes ŌĆó Improves Print Consistency ŌĆó Dot gain is more consistent on long runs ŌĆó Less sensitive to impression levels ŌĆó Reduces Operating Costs ŌĆó Faster start up ŌĆó Runs clean/ fewer start & stops ŌĆó Expands flexo capability to run against gravure and offset (short runs option) Printer / Print Buyer ŌĆó Versatile ŌĆó Small, mobile laminator footprint ŌĆó Works with solvent or thermal processing ŌĆó Leaves all options open, user can choose whether to image with standard digital or LUX digital process ŌĆó Consistent ŌĆó 1:1 Imaging from mask to plate ŌĆó Consistent plate height within image ŌĆó Reduce or eliminate effects of elevation, humidity, barometric pressure ŌĆó Value ŌĆó Preserves existing investments in digital workflow and imaging Plate Maker

- 4. 4 LUX: It is that simple Existing process LUX process Ablate Plate Digital Plate Expose Process Plate Standard Digital Plate Mem brane Remove Membrane LUX Lamination

- 5. LUX Dot Formation UV UV UV O2 O2

- 6. Optimizing Dot Profile ŌĆó Lots of dots work. Some dots work better. ŌĆō These factors seem to matter most 6 Dot Surface Morphology Shoulder AngleValley DepthEdge definition Dot Surface

- 7. Standard Digital vs LUX Digital ŌĆó Edge definition is far greater for LUX digital ŌĆó Surface roughness is little changed Standard digital exposure LUX digital exposure

- 8. Industry Recognition LUXTM flat top dot technology WINS FFTAŌĆÖs 2011 Award for Innovation 8 LUX also won the 2011 FPPA Innovator Award

- 9. Global Adoption of LUX 150+ Worldwide Installations

- 11. Better Highlights 11 1% 5% 10% Digital Digital Digital Digital Digital Digital

- 12. Sweflex 2013 Print Trial 12

- 13. Highlights 13 Better small dots, better highlight color and detail.

- 14. LUX & HD Flexo/MicroCell Standard digital SID = 1.21 Mottle = 17.8 LUX / MC16P SID = 1.35 Mottle = 4.2

- 15. MC12P vs MC12P-LUX 100 ŌĆó Edge definition is much sharper with LUX ŌĆó MicroCell pattern is much sharper with LUX Standard digital exposure LUX digital exposure

- 16. LUX makes MicroCell work better 16 1.20 1.30 1.40 1.50 1.60 1.70 1.80 Solid MC7 MC1 MC8 MC9 MC10 MC4 MC11 MC12 MC3 MC13 MC14 MC15 MC16 MC5 MC6C MC6 MG14 MG24 MG34 MG15 MG25 MG35 MG45 MG16 MG26 MG36 MG46 MG56 MC17 MC18 MC19 MC20 SIDcyan Microcell Pattern DMAX Microcell Effects DMAX DMAX LUX Higher ultimate SID with LUX, and more patterns work.

- 18. 18 Consistency: Impression Latitude LUX enables flexo printers to print with greater consistency Dot gain is less sensitive to impression -Fewer stops for adjustment -Longer runs 0 10 20 30 40 50 60 70 80 90 100 110 0 10 20 30 40 50 60 70 80 90 100 Digital MVP Digital MVP + 6mil (150 um) 0 10 20 30 40 50 60 70 80 90 100 110 0 10 20 30 40 50 60 70 80 90 100 Digital MVP + LUX Digital MVP + LUX + 6mil (150 um) Standard Digital Standard Digital + LUX 0 10 20 30 40 50 60 70 80 90 100 110 0 10 20 30 40 50 60 70 80 90 100 Digital MVP Digital MVP + 6mil (150 um) 0 10 20 30 40 50 60 70 80 90 100 110 LUX reduces dot gain from impression 30 - 60% Improvement

- 19. Consistency: Effects of Wear ŌĆó Improves Print Consistency ŌĆō Dot gain was more consistent during this long run 19 Some evidence of wear in the plateŌĆ”ŌĆ”.. But not in the print Example Digital MAX (high hardness) 0.107 in plates (2.72mm) 890k linear foot (271k meters) Press: W&H Novaflex Anilox: 900 LS / 2.2 bcm Ink: Solvent Substrate: Film

- 20. Versatility - Platemaking ŌĆó It works on all MacDermid digital plates ŌĆō Works with plates up to 50ŌĆØ x 80ŌĆØ size ŌĆō Works with plates from 0.045ŌĆØ to 0.250ŌĆØ thickness ŌĆó It adds <5 minutes to a normal digital workflow ŌĆó Backwards-compatible ŌĆō Use LUX when needed, use standard digital workflow for legacy jobs 20

- 21. 21 The Next Next Step in Flexo Printing

- 22. 22 LUX ITP: ItŌĆÖs even simpler Ablate Plate Digital Plate Expose Process Plate Standard Digital Plate LUX ITP Digital Plate

- 23. LUX ITP Solvent 23 0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100 Print Tone DMAX M100 S LUX ITP S Note: Printed with linear tone scale, 150 lpi

- 24. LUX ITP Thermal 24 0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100 Print Tone DMAX M100 T LUX ITP T Note: Printed with linear tone scale, 150 lpi

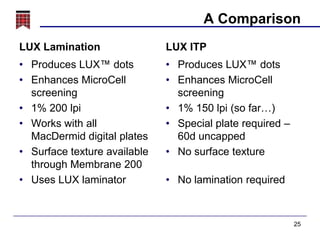

- 25. A Comparison LUX Lamination ŌĆó Produces LUXŌäó dots ŌĆó Enhances MicroCell screening ŌĆó 1% 200 lpi ŌĆó Works with all MacDermid digital plates ŌĆó Surface texture available through Membrane 200 ŌĆó Uses LUX laminator LUX ITP ŌĆó Produces LUXŌäó dots ŌĆó Enhances MicroCell screening ŌĆó 1% 150 lpi (so farŌĆ”) ŌĆó Special plate required ŌĆō 60d uncapped ŌĆó No surface texture ŌĆó No lamination required 25

- 26. LUX ITP ŌĆō The Future ŌĆó First LUX ITP plate (60d uncapped) will be commercialized in 2013 26

- 27. Industry Perspective in 2013 Flat top dots are important, butŌĆ” 1.Are they all the same? 2.What is the best way to make them? 27

- 28. ConeAnalog Compound Not all Flat Top Dots are Equivalent DigitalKodak NX DigiFlow Esko FTD Flint NExT

- 29. Our Proposition 29 Solvent Thermal Digital Dot TypeProcessing Technology We offer you more choices. We are the Global Leader in Flat Top Dot Solutions. We have the expertise to help you make the most of the options you select.

- 30. Thank You 30 http://www.macdermid.com/printing Follow us on:Learn more at: