FUJIFILM Plates manufacturing tilburg

- 1. Plate Manufacturing in Tilburg A guide to Fuji?lmĪ»s state-of-the-art plate manufacturing facility in The Netherlands. EU3037 Plates & Manufacturing Tilburg Brochure.indd 1 18/11/2011 10:54

- 2. EU3037 Plates & Manufacturing Tilburg Brochure.indd 2 18/11/2011 10:55

- 3. TILBURG PLATE MANUFACTURING Our plate philosophy Guaranteeing consistent high quality plates and uninterrupted supply requires long-term investment in sophisticated manufacturing techniques and ef?cient logistics. Fuji?lm has invested continuously in its plate supply infrastructure over many years so that printers can bene?t from consistent high quality plates, day-in, day-out. Our aim is to deliver high quality plates that make a difference to your business in the following ways: Are consistently of the highest quality Use less chemistry and water Require less processor maintenance Allow you to achieve maximum productivity Optimise ink/water balance on press Help you reduce your environmental impact A choice of plates and plate Optimised plates and pressroom technologies solutions Fuji?lmĪ»s philosophy is also to offer a choice In addition to manufacturing high quality plates, of plate technologies to match particular we go one step further. The way plates perform requirements. Our industry-leading Brillia range on-press with the relevant pressroom products of CTP plates includes both thermal and violet- is critical to achieving optimum printing results. sensitive plates, in processless, low chemistry Because Fuji?lm is one of the largest suppliers or processed variants, for commercial and of pressroom solutions in the industry, we newspaper printing applications, all with the have been able to optimise the formulation of same high quality and productivity bene?ts. our pressroom products to match our plates. Whatever the CTP application, thereĪ»s a plate By using Fuji?lm plates with our pressroom thatĪ»s designed to suit. solutions, you can be guaranteed of the very best performance and print quality. On-press development comparison: Brillia HD PRO-T3 and PRESSMAX PRO-T3 works with any fount PRO-T2 solution, but its performance PRO-T3 with normal can be further improved by fount solution using a dedicated fount from PRO-T3 with fount solution 'FountMax Fuji?lmĪ»s PRESSMAX range. Blue 30.40 AF PRO-T' This is because the formulation and 'FountMax 30.50 PRO-T' Ink density of the fount has been carefully tailored to optimise the Better on press development softening of the non-image and ink receptivity Press: Heidelberg SM74 area of the plate and therefore Fount: Substifix4% + IPA6% maximise the on-press Ink: Pantone red development process. *Actual on press development behaviour may vary according to press, ink and 10 20 30 40 50 paper conditions. These results were Number of sheets obtained from internal tests. EU3037 Plates & Manufacturing Tilburg Brochure.indd 3 18/11/2011 10:55

- 4. The technologies that make Fuji?lm plates unique Fuji?lm has been evolving the techniques and technologies used in the design and manufacture of printing plates for many years. A major milestone in this history was the introduction of one of the most successful ranges of printing plates in the world, the Fuji?lm Brillia CTP plate range, probably used by more printers around the world than any other range. The range was supplemented in 2006 by the introduction of Brillia High De?nition plates, representing the ultimate in terms of advanced plate design. The result of over a decadeĪ»s research and development into multi-graining and coating technologies, Brillia High De?nition plates raise the bar in terms of quality and productivity, and are the benchmark by which other plates are judged. They feature new micro-graining and emulsion technologies that allow wider imaging and processing latitudes, helping to achieve higher quality print more easily. The following sections highlight the key technologies and characteristics of Fuji?lm plates. Multi-graining Multi-graining is the process by which the surface of the aluminium is physically and chemically treated so that very ?ne pores and micropores are created. Fuji?lm has ?ne-tuned the techniques used to achieve this over a long period of time to produce a unique MultiGrainTM manufacturing process. The above images highlight the different stages of the micro-graining process which together deliver the following bene?ts: Superb tonal reproduction Larger primary grains are receptive to water for superb tonal reproduction. Long runs and better scum resistance Smaller honeycomb grains deliver longer print runs and better scum resistance. Optimum ink/water balance Micropores further enhance surface durability for optimum ink/water balance. EU3037 Plates & Manufacturing Tilburg Brochure.indd 4 18/11/2011 10:55

- 5. TILBURG PLATE MANUFACTURING Coatings Brillia plates have a number of coating layers, each designed to optimise the overall performance of the plate. The plates vary in their construction, with different coating layers depending on the speci?cation of the plate, but the diagram below highlights the basic structure: High sensitivity Better productivity polymerisation technology Better quality High de?nition Brillia HD emulsion technology High performance Better press performance MultiGrainTM technology Sustainable investments Signi?cant R&D resources have also been directed into the development of printing plates that use the minimum amount of chemistry and therefore have minimal impact on the environment. This has resulted in the introduction of two main types of plate, processless and low chemistry (or Ī«lo-chemĪ»), both setting new standards in commercial and newspaper printing applications. Processless Low chemistry or Ī«lo-chemĪ» Processless plate production represents the simplest way to Thanks to state-of-the 1,200 L Chemistry use 1,200 make plates. Once the plate has been imaged in a platesetter, it art plates, chemistry and is mounted directly on the press where the removal of the plate processor software, Fuji?lm Typical thermal CTP 1,100 coating has been cleverly integrated into the start-up of the Ī«lo-chemĪ» plate solutions press. There is complete elimination of the processor, associated can achieve the industryĪ»s chemistry, energy required to power the processor, water and lowest chemistry use ?gures 1,000 waste from plate production. (with cleaner working chemistry) and huge 900 reductions in water use and maintenance time. 800 700 This graphic highlights the amount of chemistry used 600 PLATESETTER PLATE PROCESSOR PRESS by different plate solutions. 520 L The calculations assume 500 Typical thermal 10,000 B1 plates are Ī«chemistry-freeĪ» produced over a 1-3 month 400 L 400 period. 300 216 L 200 HD LH-PJE HD PRO-V litres 100 EU3037 Plates & Manufacturing Tilburg Brochure.indd 5 18/11/2011 10:55

- 6. Plate manufacturing in Tilburg The production site in Tilburg manufactures a number of Fuji?lm products, Number of employees 800 including photo paper for the consumer imaging market, but for a number of Year of creation 1982 years the primary product manufactured at the site has been printing plates. Surface area 63 hectares The ?rst production line designed for the manufacture of printing plates (PS-6) was opened in 1991, the second (PS-8) in 2006, and with the completion of Facilities the latest plate line (PS-10) in 2011, the facility is now one of the largest plate Production line for photo paper production sites in the world. Three production lines for offset plates 1982 Fuji?lm Tilburg opened Tilburg Research Laboratory 1991 Opening of research labs, ?rst plate line, PS-6 and distribution centre Testing facility in former ?lm roll factory 1993 ISO 9002 Certi?cate awarded, Quality; now ISO 9001 Large distribution centre 1993 First plate line (PS-6) expanded Market coverage 1997 ISO 14001 Certi?cate awarded (Environmental Management System) Europe 2004 First plate line (PS-6) expanded again Africa 2006 Opening of second CTP plate line, PS-8 Middle East 2011 Opening of third CTP plate line, PS-10 4 3 1 2 6 5 9 7 8 Plate manufacturing in Tilburg 1 Distribution centre, 1991 4 Tilburg research laboratory 7 PS-6, 1991 2 P1 Colour paper, 1984 5 Of?ces 8 PS-8, 2006 3 Utilities 6 Test facility 9 PS-10, 2011 EU3037 Plates & Manufacturing Tilburg Brochure.indd 6 18/11/2011 10:55

- 7. TILBURG PLATE MANUFACTURING Consistent high quality plates delivered day-in, day-out High quality printing plates are an essential component of offset print production. However, quality means nothing if it is not achieved consistently. Fuji?lm achieves consistent high quality plate production thanks to the meticulous attention to detail and level of automation throughout production, in conjunction with a rigorous quality and inspection process. Manufacturing is so advanced on all three plate lines that every stage up until the ?nal process of packing is automated (even the delivery to and from the warehouse of each 7 tonne coil of aluminium is automated). Ultimately, each plate that is manufactured is scanned for defects, with any plate exhibiting a defect immediately scrapped. New PS-10 plate line The new PS-10 plate line opened in December 2011 is the most sophisticated plate manufacturing line in the world. It is designed not only to manufacture Brillia processed and Ī«lo-chemĪ» plates, but also Fuji?lmĪ»s most advanced printing plate ever, Brillia HD PRO-T3. Construction of the PS-10 plate line during 2011 EU3037 Plates & Manufacturing Tilburg Brochure.indd 7 18/11/2011 10:55

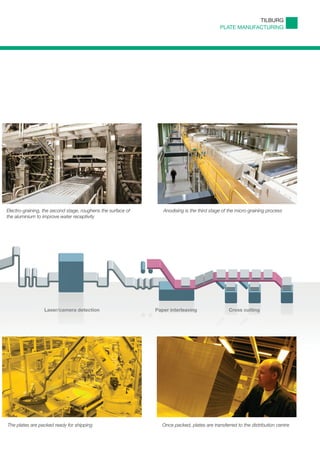

- 8. Automated manufacturing process The manufacture of printing plates at Tilburg is an automated, 24/7 process which involves a number of complex stages. The entire process is continuous, with the diagram below highlighting the key stages. Aluminium coil store holds over 400 coils of premium grade Unwinding and joining process ensures consistent 24/7 aluminium at any one time operation Unwinding and joining Buffer Brush-graining Etching and cleaning Electro-graining Etc A multi-layer light sensitive coating is applied to the grained The coated layers are dried prior to automated laser aluminium inspection EU3037 Plates & Manufacturing Tilburg Brochure.indd 8 18/11/2011 10:55

- 9. Buffer used to ensure continuous operation during joining Brush-graining is the ?rst stage of the micro-graining process process Etching and cleaning Anodising Cleaning Coating and drying Interleaf paper is placed on top of the coated aluminium web Process inspection represents the ?nal check after the just prior to cutting, protecting the plates before being packed individual plates are cut EU3037 Plates & Manufacturing Tilburg Brochure.indd 9 18/11/2011 10:55

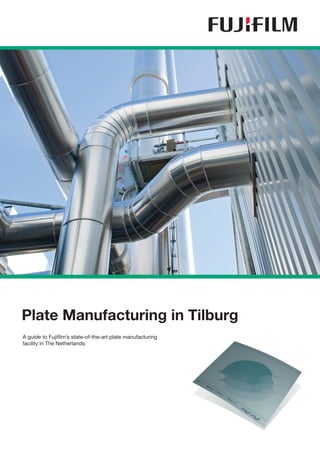

- 10. TILBURG PLATE MANUFACTURING Electro-graining, the second stage, roughens the surface of Anodising is the third stage of the micro-graining process the aluminium to improve water receptivity Laser/camera detection Paper interleaving Cross cutting The plates are packed ready for shipping Once packed, plates are transferred to the distribution centre EU3037 Plates & Manufacturing Tilburg Brochure.indd 10 18/11/2011 10:55

- 11. PS-10 plate line, opened in December 2011 EU3037 Plates & Manufacturing Tilburg Brochure.indd 11 18/11/2011 10:55

- 12. Sustainable production Fuji?lm prides itself on its investment in sustainability, and the Tilburg manufacturing site is a prime example. The ability to manufacture plates locally in itself helps to reduce the carbon footprint of plate production, as it reduces the energy consumed in the transportation process. This is one of the reasons why Fuji?lm has invested heavily in the expansion of the Tilburg production site. The site itself achieved ISO 14001 certi?cation in 1997, and has been implementing sustainability improvements every year. The ultimate aim of the site is to be 100% CO2 neutral in everything it does, and this objective has resulted in a number of signi?cant recent investments. New wind farm In October 2011, the installation of ?ve wind turbines was completed. The ?ve turbines, developed in partnership with ENECO and having a combined capacity of 10MW, are capable of producing the equivalent amount of energy that 6,000 households use in one year, and are set to supply approximately 20% of the total energy used by the 63 hectare Tilburg site as a whole. This represents a 12,000 tonne reduction in CO2 emissions per year. Three of the turbines are 95 metres high, with the maximum tip height (tower plus blade) of 140 metres. The other two wind turbines are 15 metres lower, in connection with the approach path to the local Gilze-Rijen airport. Partner company ENECO feeds the electricity generated by the wind turbines directly into the Fuji?lm Tilburg electricity supply. Over 99% of waste produced Co-generative Thermal Oxidiser at Tilburg is recycled, regenerated or reused. Co-generative Thermal Oxidiser (CTO) Other investments include a co-generative thermal oxidiser which has been built in conjunction with the new PS-10 plate line. This is essentially a large afterburner, which uses gases and waste solvents produced as a by-product of the plate manufacturing process for fuel. The steam which is generated by the CTO is converted into electricity and hot water in a Combined Heat Power Plant. Low pressure steam can be used in summer to make chilled water. The yield of these processes is Recycled >92%, and will help to reduce CO2 emissions by a further 5,500 tonnes per year. Water recycling facility The company has also installed a water recycling facility, consisting of two large water puri?cation units, on site. However, Fuji?lm is also investigating the possibility of cleaning some of the waste water the site generates for reuse within the production process, as well as the option of constructing a complete waste water treatment system on site, in collaboration with three Regenerated neighbouring companies. Reused Waste dumping With these and other sustainability measures in place, Fuji?lm Tilburg estimates that it currently Disposed reuses 13% of the waste it produces, recycles 68%, regenerates 18% and so is left with less than 1% of the total site waste to dispose of. EU3037 Plates & Manufacturing Tilburg Brochure.indd 12 18/11/2011 10:55

- 13. Waste water treatment Co-generative Thermal Oxidiser EU3037 Plates & Manufacturing Tilburg Brochure.indd 13 18/11/2011 10:55

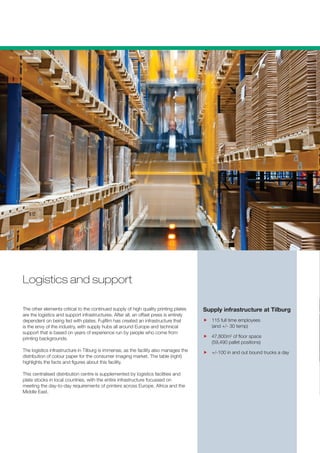

- 14. Logistics and support The other elements critical to the continued supply of high quality printing plates Supply infrastructure at Tilburg are the logistics and support infrastructures. After all, an offset press is entirely dependent on being fed with plates. Fuji?lm has created an infrastructure that 115 full time employees is the envy of the industry, with supply hubs all around Europe and technical (and +/- 30 temp) support that is based on years of experience run by people who come from printing backgrounds. 47,800m2 of ?oor space (59,490 pallet positions) The logistics infrastructure in Tilburg is immense, as the facility also manages the +/-100 in and out bound trucks a day distribution of colour paper for the consumer imaging market. The table (right) highlights the facts and ?gures about this facility. This centralised distribution centre is supplemented by logistics facilities and plate stocks in local countries, with the entire infrastructure focussed on meeting the day-to-day requirements of printers across Europe, Africa and the Middle East. EU3037 Plates & Manufacturing Tilburg Brochure.indd 14 18/11/2011 10:55

- 15. TILBURG PLATE MANUFACTURING World-class technical support In addition to building a supply network thatĪ»s second to none, Fuji?lm also prides itself on the quality of its technical support. Fuji?lm has built up a comprehensive network of highly skilled plate technicians, many of which are ex-printers. This means that not only do they understand all aspects of plate production, Customised packaging they also understand print applications and the demands of Fuji?lm is also able to offer bespoke packaging to meet the modern-day presses giving them the ability to deal with any needs of speci?c customer requirements, in particular to reduce issue that may arise. the amount of material used in the packaging and transportation of plates. This has the bene?t of reducing the amount of waste packaging created as a by-product of the plate supply chain, and importantly the burden on the printer to dispose of it. EU3037 Plates & Manufacturing Tilburg Brochure.indd 15 18/11/2011 10:55

- 16. EU3037 Plates & Manufacturing Tilburg Brochure.indd 16 18/11/2011 10:56

- 17. TILBURG PLATE MANUFACTURING World-wide plate manufacturing infrastructure Ī░Wherever you Fuji?lmĪ»s plate manufacturing facility in Tilburg, The Netherlands is one of four global production centres all dedicated to delivering world-class printing plates. Advanced automation and operate in the world state-of-the-art quality control at each facility results in the highest standards of production, so and whatever you wherever you operate in the world and whatever you need, Fuji?lm wonĪ»t let you down. need, Fuji?lm wonĪ»t let you down.Ī▒ 1 2 4 3 1 Tilburg 2 Greenwood 4 Yoshida-Minami Netherlands USA Japan Serves the European, Serves the North and Large Graphic Arts R&D African and Middle Eastern South American markets facility in Japan, employing markets $100M investment in the 500 people Ć96M investment in new plate line in 2005 Serves the Japanese and third PS-10 plate line in Uses local land?ll methane Asian markets December 2011 to reduce greenhouse Initial source of production New wind farm and other emissions, with the aim for all Fuji?lm plates sustainable projects of producing 40% of its completed in 2011 energy through methane 3 Suzhou China Serves the Chinese and Asian markets New plate manufacturing plant completed in March 2007 EU3037 Plates & Manufacturing Tilburg Brochure.indd 17 18/11/2011 10:56

- 18. Process plant photography: Chris Veen and Frans Jan Fortunati This brochure was printed in the UK by Severnprint, an ISO 14001 and FSC-certi?ed printer using Brillia HD PRO-T3 processless plates and an alcohol-free litho printing process. It is printed on an FSC-certi?ed recycled paper, using vegetable-based inks and 100% renewable energy using the SylvaPack environmental print route. All jobs printed within this scheme generate a donation to Tree Aid, with over ?20,000 raised so far by Severnprint. Please contact your local Fuji?lm partner for further information FUJIFILM Manufacturing Europe B.V. Oudenstaart 1 5047 TK Tilburg Netherlands T +31 13 579 19 11 info@fuji?lmtilburg.nl POWER TO SUCCEED 3037 T11 EU3037 Plates & Manufacturing Tilburg Brochure.indd 18 18/11/2011 10:56