Fundamentals of Machine Vision- Lighting

- 1. Part 3 in a Series: Illumination Terms and Techniques ┬® 2014, Pete Kepf, All Rights Reserved Pete Kepf, CVP www.kepf.me

- 2. Pete Kepf, CVP www.kepf.me ’é© Overview: Lighting is critical variable ’é© Applications and their lighting schemes ’éĪ Lighting ’éĪ Lenses ’éĪ Sensors ’é© What do you want your image to look like? ’éĪ Software ’éĪ Part Attributes

- 3. Pete Kepf, CVP www.kepf.me ’é© Machine Vision is the use of a computer to acquire visual information and/or extract image information for purposes of data storage or automatic decision making.

- 4. Pete Kepf, CVP www.kepf.me ’é© Motion/ Robot Guidance ’é© Defect/ Flaw Detection ’é© Inspection/ Grading/ Sorting ’é© Identification/ Verification ’é© Data Acquisition ’é© Measurement/ Gauging

- 5. Pete Kepf, CVP www.kepf.me Vision Components ’é© Lens ’é© Camera ’é© Processor ’é© Input/ Output Peripherals ’é© Lighting ’é© Frame/ Enclosure ’é© Controls/ Software ’é© Part Handling/ Reject/ Sorter

- 6. Pete Kepf, CVP www.kepf.me Motion: Front Lighting Near IR Flaw: Front Lighting Blue Filter Measurement Back Lighting Visible Sort: Front Diffuse Visible Measurement Structured Pattern Projector Count Front Line Visible

- 7. Pete Kepf, CVP www.kepf.me ŌĆó High S/N ŌĆó High Contrast ŌĆó Even Distribution ŌĆó Repeatable ŌĆó Product Variability ŌĆó Ambient Conditions

- 8. Pete Kepf, CVP www.kepf.me Light Source ’é© Frequency ’é© Brightness ’é© Angle ’é© ŌĆ£ShapeŌĆØ ’é© Duration Object ’é© Surface ’éĪ Reflectivity ’éĪ Geometry What do you need the image to look like?

- 9. Pete Kepf, CVP www.kepf.me Reflection: Angle of Incidence = Angle of Reflection Absorption: Frequency Specific Refraction: Affects angle and Frequency Scattering: Multi- angle Reflection

- 10. Pete Kepf, CVP www.kepf.me Reflectivity: Polish/ Coating Scattering: Dirt/ Scratch Absorption: Lens Material Refraction: Lens Material

- 11. Pete Kepf, CVP www.kepf.me Reflectivity: Polish/ Coating Scattering: Dirt/ Scratch Absorption: Sensor Material/ Filter Refraction: Sensor Material

- 12. Pete Kepf, CVP www.kepf.me Back Light Pattern Projector Line Light Ring Light Axial Light Dome Light

- 13. Pete Kepf, CVP www.kepf.me ’é© Frequency/ Wavelength (Color) ’é© Polarization ’é© Intensity (Brightness) ’é© Direction (Soft/ Spectral/ Polarized) ’é© Duration (Constant/ Pulse)

- 14. Pete Kepf, CVP www.kepf.me Filter Source and Camera Source: www.thermalcamerarentals.com

- 15. Pete Kepf, CVP www.kepf.me (Previous: Halogen- Fluorescent- Xenon; Now: LED) Source: www.thermalcamerarentals.com Wavelength (nanometers) = 3,000,000 / Color temp (Kelvin).

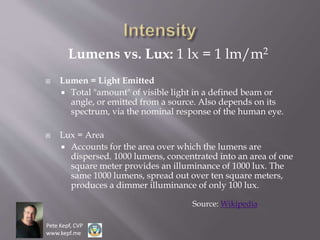

- 16. Pete Kepf, CVP www.kepf.me Lumens vs. Lux: 1 lx = 1 lm/m2 ’é© Lumen = Light Emitted ’éĪ Total "amount" of visible light in a defined beam or angle, or emitted from a source. Also depends on its spectrum, via the nominal response of the human eye. ’é© Lux = Area ’éĪ Accounts for the area over which the lumens are dispersed. 1000 lumens, concentrated into an area of one square meter provides an illuminance of 1000 lux. The same 1000 lumens, spread out over ten square meters, produces a dimmer illuminance of only 100 lux. Source: Wikipedia

- 17. Pete Kepf, CVP www.kepf.me Seite: 17 Top (or Front) Light source and image sensor are on the same side of the part. ’é© Diffuse ’é© On-axis ’é© Dark/ Bright Field Back Light source and image sensor are on opposite sides of the part. ŌĆó Diffuse ŌĆó Collimated Structured Light source has a known geometry. ŌĆó Line ŌĆó Grid

- 18. Pete Kepf, CVP www.kepf.me Uses: ŌĆó Small Parts ŌĆó Structured Light

- 19. Pete Kepf, CVP www.kepf.me Diffuse On-axis Bright/ Dark Field

- 21. Pete Kepf, CVP www.kepf.me Shadow-less illumination Applications: ŌĆó specular surface ŌĆó diffused surface General-purpose

- 22. Pete Kepf, CVP www.kepf.me Applications ŌĆó imaging ŌĆó web ŌĆó line scan Features ŌĆó adjustable lens ŌĆó enhanced cooling ŌĆó low current consumption Uses ŌĆó Road surface inspection ŌĆó Bottle inspection ŌĆó Carpet Inspection ŌĆó Print Inspection

- 23. Pete Kepf, CVP www.kepf.me Useful for: ŌĆó Robot Work Cells ŌĆó Top Light Assembly ŌĆó Reflective Parts

- 24. Pete Kepf, CVP www.kepf.me Uses: ŌĆó Metal and chromed bearing surface inspection ŌĆó CD / DVD assembly inspection ŌĆó Package inspection of glossy plastics and finishes ŌĆó Inspection of metal stampings and parts with electrical contacts ŌĆó Automotive applications ŌĆó Medical device packaging and tray packs ŌĆó Pharmaceuticals blister form fill and trim ŌĆó Cosmetics and makeup packaging equipment and lines ŌĆó Diffused Tube Lights are meant for inspecting elongated parts ŌĆó Metal and chromed bearing surface inspection Image of Sphere

- 25. Pete Kepf, CVP www.kepf.me Uses: ŌĆó Sphere inspection for surface flaws ŌĆó Ball bearing inspection ŌĆó CD/DVD label inspection ŌĆó LCD display inspection ŌĆó Automotive part inspection

- 26. Pete Kepf, CVP www.kepf.me Uses ŌĆó Illumination of scratches on reflective surfaces ŌĆó Ball grid array (BGA) inspection ŌĆó Water contamination inspection ŌĆó Bottle Cap inspection ŌĆó Microscopic stage illumination ŌĆó Inspect molded epoxy parts to uncover imperfections such as cracks, bubbles, and structural damage

- 27. Pete Kepf, CVP www.kepf.me Diffuse Collimated Uses: ŌĆó Absence/presence of objects ŌĆó Defect detection in glass/plastic containers ŌĆó Object tracking (Fish in aquarium) ŌĆó PCB (printed circuit board) board assembly through-hole lead detection ŌĆó Web inspection (pin-holes in web) ŌĆó Bottle cap detection ŌĆó Bolt/Bolt thread inspection ŌĆó Glass Sheet defect detection ŌĆó Sub-pixel dimensional inspection

- 28. Pete Kepf, CVP www.kepf.me Useful for: ŌĆó Gauging ŌĆó Measurement

- 29. Pete Kepf, CVP www.kepf.me Seite: 29 Line Grid

- 30. Pete Kepf, CVP www.kepf.me Useful for: ŌĆó Structured Light ŌĆó Height Derivation

- 31. Pete Kepf, CVP www.kepf.me ’é© Constant ’éĪ Non-Moving Parts ’éĪ Use Care with Ambient ’éĪ Typically large area ’éĪ No Controller ’é© > 10 microseconds ’éĪ Line Speeds up to 1200 parts/ minute ’éĪ LED with Controller ’éĪ Configurable Form Factor ’é© > 100 nanoseconds ’éĪ Part speeds up to 3500 feet/ second ’éĪ LED with Controller ’éĪ Configurable Form Factor

- 32. Pete Kepf, CVP www.kepf.me ’é© Goals: ’éĪ High S/N ’éĪ High Contrast ’éĪ Even Distribution ’éĪ Repeatable ’é© Variables ’éĪ Frequency ’éĪ Brightness ’éĪ Angle ’éĪ ŌĆ£ShapeŌĆØ ’éĪ Duration ’é© Other Components ’éĪ Lens ’éĪ Camera Sensor ’é© Some Lighting Terms ’éĪ Top/ Front ’éĪ Back ’éĪ Structured ’éĪ On-axis ’éĪ Diffuse ’é© Lighting ŌĆ£WŌĆØ