garlic peeling processing line by bway.pdf

- 1. Garlic peeling Machine by air blaster

- 3. Garlic peeling machine by air blaster ŌĆó Garlic peeling machine ----means remove the outer skin of garlic by electric machine ŌĆó By air blaster----means not by sand roller or water. Just by air flow to blow off out first layer of skin

- 4. COMPARISON OF 3 WAYS OF GARLIC SKIN REMOVING WAYS Manual hand peel Clove peeling machine Garlic peeling machine by air blaster Picture Speed of Peeling Very slow Medium, Can be kgs per hour, need to separate the garlic clove firstly Fast ,500-1000kg/hour , can put whole garlic pod Intactness of peeled onion Garlic tend to bruise, bleed, and rot easily High rate of collision, damage inside of garlic,can not storage long time NO damage garlic Precisely blow off the dry skin Risks Yes,hot hands and dust pollution No No

- 5. Working principle of garlic peeling machine Brand new way of Peeling with Airflow. The valve controls the strength of the airflow. Firstly, put garlic into feeder then depoding machine would gentle separate the cloves of garlics. And then blower would Precisely blow off the dry skin. The inside of the garlic is intact. Can save more than 1 million usd in labor costs every year.

- 6. Advantages of Garlic peeling machine ŌĆó One machine fits to different size of Garlic, put whole garlic pod, no need to separate into clove by hands ŌĆó Non-lossy peeled garlic can be storage for longer time ŌĆó The workshop is no more dust pollution and hot fingers, No water wastage

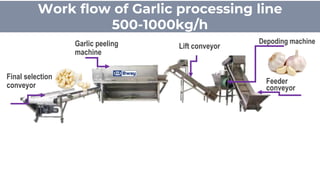

- 7. Work flow of Garlic processing line 500-1000kg/h Feeder conveyor Final selection conveyor Garlic peeling machine Depoding machine Lift conveyor

- 8. Features of Garlic peeling machine ŌĆó Capacity: 500-1000kg/h ŌĆó Requested compressor air: 37kw ŌĆó Easy to control the air strenghth by valve

- 9. CONTACT US Now Phone/whatsapp 008613602468232 Email bwaypeeler@gmail.com Bwaymachine.top Our Clients from England, UK, Mexico and turkey, Suitable for exporting factory, supplier for supermarket, or ready to eat shops.