GFRG Rapidwall Sustainable Load Bearing Building System

- 1. GFRG BUILDING SYSTEM MARKETED BY : BILTECH BUILDING ELEMENTS LTD. PRESENTED BY : RAJDEEP CHOWDHURY

- 2. Avantha Group is one of IndiaŌĆÖs leading business conglomerates. Having footprint in 90 countries. US$ 4 billion Avantha Group has 25,000 employees worldwide. Its successful entities includes : ’āś BILT ŌĆō Paper & Pulp ’āś Crompton Greaves ŌĆōPower Equipment ’āś The Global Green Company- Food processing ’āś Biltech Building Elements Ltd. ŌĆō Building Material ’āś Avantha Power & Infrastructure ŌĆō Power generation ’āś Avantha Technologies ŌĆō IT & ITES.

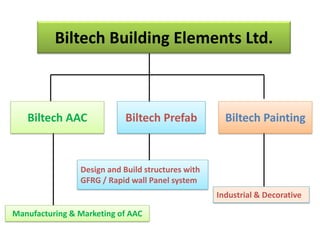

- 3. Biltech Painting Biltech Building Elements Ltd. Design and Build structures with GFRG / Rapid wall Panel system Biltech PrefabBiltech AAC Manufacturing & Marketing of AAC Industrial & Decorative

- 4. Conventional building materials are : ’ü▒ Energy intense ’ü▒ Demand is growing ’ü▒ Materials like river sand & water is scarce ’ü▒ CostŌĆÖs spiraling up ’ü▒ Increases CO2 emission & impact on environment & ’ü▒ Construction is time consuming Therefore , there is a need for an alternative building materials & fast construction methods for housing

- 5. RATIONALE Pospho-gypsum is produced as byproducts of chemical , fertilizer industries and due to its limited usage , this waste is becoming an environmental problem. The Rapidflow Calciner and Rapidwall Technology can help to overcome these problems by turning waste into plaster and the plaster into homes that are environmentally friendly, non- polluting, energy efficient and aesthetically pleasing. PHOSPHO GYPSUM PLASTER BUILDING MATERIAL (RAPIDWALL)

- 6. GFRG / RAPIDWALL - A REVOLUTIONARY BUILDING MATERIAL ’ü▒ GFRG/ Rapid wall is load bearing pre-fabricated walling panel. This is suitable for rapid mass scale building construction was originally developed and used since 1990 in Australia. ’é© GFRG/ Rapid wall is manufactured using Gypsum as a core material , which is generated as by product in the process of manufacturing fertilizers ’ü▒ GFRG/ Rapid wall is manufactured at RCF , Mumbai and FRBL , Kochi. ’ü▒ GFRG/ Rapid wall is suitable for load-bearing applications and as well as hybrid Construction in multi-storey buildings.

- 8. reinforced by glass rovings Micro-strand glass roving role ŌĆó Rapidwall panels are 12m long , 2.85m high and 0.124m thick. ŌĆó Made from Gypsum, Glass Rowing, and Special Chemicals. ŌĆó Made from Australian Technology GFRG / Rapid wall Panel Tensile strength of glass roving (single filament) is 3100-3800 Mpa (tensile strength of glass roving is much higher than even that of steel used for concrete reinforcement which is maximum @ 500 Mpa) Elastic Modulus of glass roving is 76-78 Gpa This provide very high load bearing capability to the panel making into a composite material.

- 9. Glass Fiber Reinforced Gypsum (GFRG) Panel, called RAPIDWALL . It is an ideal alternative building material to replace conventional walling system. MATERIAL

- 10. Advantage of GFRG/ Rapid wall Building system ŌĆó Light weight ŌĆó Less Input material i.e. Steel , cement . sand and water ŌĆó More Carpet area ŌĆó Faster Construction ŌĆó Less Labor Input ŌĆó Eco Friendly , controls CO2 Emission ŌĆó Saving of recurring energy cost ŌĆó Resistant to Earthquake , Cyclone & fire ŌĆó Free from Corrosion , rot & termite

- 11. Compressive strength (Empty panel ): 73.10 Kg/cm2 (Concrete infill ): 180.70 Kg/cm2 Flexural Strength empty panel : 21.25 Kg/cm2 concrete infill : 20.80 Kg/cm2 Tensile strength 28.8 kN/m Ductility 4.11 Water absorption < 2% (24 hrs) Fire resistance 4 hrs rating 700 oC to 1000 oC. Thermal resistance 0.36 R Sound Transmission Class - STC 40 Free from Corrosion Axial vertical load on empty panel of 2.85m high x 1m : 14.04 tons Axial vertical load on concrete infilled panel of 2.85m high x 1m : 154 tons Rot & termite proof Light weight 40 Kg / m2 (1/8th weight of concrete) Net Density 1140 Kg / m3 Earthquake resistant: test withstood earthquakes up to Richter Scale 8 Eco-friendly (green material) (raw material recycled waste & no emission of CO2 ) Saving : ŌĆóWater ŌĆóRiver sand ŌĆóAgri top soil ŌĆóCement ŌĆóSteel Saves time of construction ŌĆó Low maintenance cost ŌĆóSaving in recurring energy cost Cost-effective (affordable cost) Properties of GFRG/ Rapid wall Panel

- 12. TESTS ON GFRG / RAPIDWALL List of tests : ( carried out by IIT Chennai ) ’ü▒ Water absorption Test ’ü▒ Rain Water Penetration Test ’ü▒ Compressive Strength Test ’ü▒ Fire Resistance Test ’ü▒ Durability Test ’ü▒ Corrosion Test ’ü▒ Impact Test ’ü▒ Nailing & pull out Test ’ü▒ Sound Transmission Test ’ü▒ Test to find Elastic Modulus

- 13. Tests carried out by SERC, CSIR Chennai ( 2002) 1. Seismic performance of Rapid wall building system 2. Investigations of behavior of Rapid wall Panel 3. Compressive strength with and without concrete in-fill ’é© Flexural test with Single Point Load on large panel with & without concrete infill ’é© Flexural Test by double point load with or without concrete infill ’é© Axial Compression{ Vertical Load test} on high panel with & without concrete in- fill

- 14. Structural Design Manual & PACS

- 15. Applications ŌĆó In apartment buildings, some up to 14 storey's, concrete filled Rapidwall panels have been used very successfully in load-bearing construction to support combined lateral and vertical loads and to support vertical loads only. Load-bearing walls in multi-storey construction ŌĆó Rapidwall panels, either unfilled or concrete filled, can be used to support domestic structures. Unfilled Rapidwall can be used to support domestic structures up to two storey's providing the suspended floor is constructed from timber. Individual Dwelling Construction ŌĆó Unfilled 100 millimeter Rapidwall (current panels are 124 mm) will provide an FRL of 180/120/60 and concrete filled Rapidwall an FRL of 240/240/240. Walls that require high fire rating ŌĆó Insulation filled Rapidwall panels have been successfully used in cottage construction as structural roof elements over which battened roof sheeting is placed. Roof panels ŌĆó When used as permanent-formwork for suspended concrete slabs, services such as electrical or plumbing can be carried in the cells, noise attenuation between floors is improved and a finished plaster ceiling is obtained. Permanent formwork for suspended slabs ŌĆó Rapidwall has been used extensively for domestic fencing providing a high quality finish to both neighboring properties. Uniquely Rapidwall can be placed directly in trenches and sand filled to provide solid foundation free fences up to two meters high. Compound Walling

- 16. Manufacturing Process & Plant

- 17. Section of GFRG/ Rapid wall Panel

- 18. Various construction joints in GFRG/ Rapid wall

- 21. Design of Floor Slab GFRG panel with reinforced concrete micro beams and screed concrete can be used as a slab both as floor slab as well as roof slab for buildings. The basic design philosophy as the same is that given in IS: 456-2000, corresponding to slab behavior . 2Y-12 + 1Y-8 Micro-beams

- 22. 120 Inside face Joint sealant Powder coated steel / aluminium window / door frameJoint sealant Outside face FixerClamps (b) TYPICAL WINDOW OPENING / WINDOW FRAME FIXING (a) TYPICAL DOOR OPENING / DOOR FRAME FIXING FFL Section A - A A A AA Typical door opening / door frame fixing DOOR & WINDOW FIXING

- 23. SECTION Basin - mounted tapware - Note :- wall plumbing should not be placed inside Rapidwall party walls Wall - mounted basin Rapidwall cores to be concrete filled. Basin bracket to be bolted through to outer face of panel with fixing to manufactuers recommendations. Countersink and flush finish to face. 120mm Rapidwall panel Waterproof membrane by others Floor level Rapidwall panel to sit setdwon, not in setdown 120mm Rapidwall panel concrete fill cores immediately behind basin. Fixing to extend through concrete - flush over bolt SECTIONAL PLAN Wall - mounted basin Base for fixing tiles. Water pipe Bridging tap / body screw fixed to blocking using galvanised metal straps and 6g x 25 Bugle head screws. Provide flexible sealant or approved selected gasket Provide flexible sealant or approved selected gasket Wadding (note the formed hole must be large enough to accommodate the positioning of the C - section member) Waterproof membrane Wall tiles - direct stick Provide wadding to 60mm long section of steel (100.12. (102 x 51 nom) Screw fix steel member to Rapidwall using 2 Nos 8g x 30 Bugle head screws 50mmfixingcentres 120mm Rapidwall panel R SECTIONAL PLAN R Fixing of sanitary ware & piping BASIN AND URINAL FIXING

- 24. METHOD & SEQUENCE OF CONSTRUCTION OF HYBRID SYSTEM

- 25. GFRG panels in RCC framed Structure GFRG/ Rapid wall panels can be used as infill walls / slabs in conventional RCC Framed construction . This system is suitable for low rise to high rise building without any limitation in the number of storey's. The use of GFRG/ Rapid wall panels and composite floor panels can be integrated with the construction of column & beams

- 27. GFRG panel in Hybrid Building

- 28. Some Projects with GFRG / Rapid wall

- 29. Picture Gallery

- 30. HIGH RISE APARTMENTS ŌĆ£CROWN OF THE HILLŌĆØ at Pennant Hill, Sydney. MARBURY, Sydney.

- 31. Boundary Walling with GFRG

- 32. Demo Building after completion

- 33. Service matrix offered by BILTECH ŌĆó Project Planning ŌĆó Designing & Estimation ŌĆó Construction & commissioning ŌĆó Project Management

- 34. Sequence of Construction of G+1 storied Demo Building in IIT Madras campus ŌĆó Structural design by IIT Madras & BMTPC ŌĆó R&D support by Dept. of Science & Technology

- 35. Various stages of Construction

- 37. THANK YOU ! For any Queries Please Contact Rajdeep Chowdhury M:- +91-9811076657 E:- rajdeep.chowdhury@bilt.com