Giatech Airframe Wire Development

- 2. Engineering Driven Change As aerospace engineers have responded to the performance requirements of their customers, whether commercial or military, innovation in the design and manufacture of high temperature, high performance insulation systems have been challenged to keep pace. Improvements in space and weight savings without sacrificing the thermal and mechanical performance of the wire has been one of the key challenges. 22 Nov 2011

- 3. Advances in Wire Technology ŌĆó PVDF (1966) ŌĆó Peek (1970ŌĆÖs) ŌĆó ETFE (1970ŌĆÖs) ŌĆó Polyimide (1972) ŌĆó XL-ETFE (1978) ŌĆó Composites (1993) ŌĆó M22759/80A-/92A (1999) 22 Nov 2011

- 4. Engineering Issues Leading to Composite Development Prior to the introduction of earlier versions of the composite constructions in use now, most aircraft were wired with either a Polyimide (Kapton) or XLETFE insulation. It was recognised that both of these insulation systems had shortcomings and two separate development programmes running concurrently led to the creation of the type of composite construction used extensively today. 22 Nov 2011

- 5. Composite Development ŌĆó Two Development Programmes ŌĆō US Air Force CRAD ŌĆō Wright Patterson AFB (1989-1991) ŌĆó Replacement for MIL-W-81381 ŌĆó Comparative Study of 14 Candidates ŌĆō SPI ŌĆō McDonnell Douglas (1996-1999) ŌĆó Hydrolytic Stability, Arc Propagation, UV Markability, Termination Issues ŌĆó Acceptance by US Navy, Air Force, Army ŌĆó F/A-18EF, F-15, C-17, AH-64D 22 Nov 2011

- 6. Engineering Issues Leading to Composite Development ŌĆó ARC Resistance (performance) ŌĆó Hydrolytic Stability (performance) ŌĆó Flexibility (shop handling) ŌĆó Notch Propagation (performance) ŌĆó Smoke Generation (performance) ŌĆó Insulation Weight and size (performance) ŌĆó Mechanical Toughness (performance + shop handling) ŌĆó Laser Marking (performance + shop handling) 22 Nov 2011

- 7. Performance Comparison 1974 1986 1999 M81381 M22759 M22759 Characteristic "Kapton" "XL-ETFE" "Composite" Arc Resistance R G G Hydrolytic Stability R G G Flexibility R G G Notch Propagation R Y G Temperature Performance G Y G Smoke Generation G R G Insulation Weight G Y G Mechanical Toughness G Y G Laser Markability R G G 22 Nov 2011

- 8. MIL-W-22759 ŌĆ£CompositeŌĆØ Abbreviations Tape 1, applied with FP = Fluorocarbon Polymer 51-54% overlap PI = Aromatic Polyimide PTFE = Polytetraflouroethylene Tape 2, applied with 51-54% overlap Advantages Thin Wall Insulation (Hook-Up) Tape 1 .45 mil FP / .65 mil PI / .1mil FP Temperature Performance (260C) Tape 2 2 mil Unsintered PTFE Mechanical Toughness Total Nominal Thickness 5.8 mil Hydrolytic Stability Arc Resistance Smoke Generation Normal Wall Insulation (Airframe) Flexibility Tape 1 .5 mil FP / 1 mil PI / .5mil FP Low Weight Tape 2 2 mil Unsintered PTFE Laser Markable Total Nominal Thickness 7.6 mil Disadvantages Minor - Unique Blades 22 Nov 2011

- 9. SEAMLESS First choice for Airframe Wire today! ŌĆ£The look of extrusion with toughness of tape wrap all rolled into one.ŌĆØ 22 Nov 2011

- 10. Remember these? ŌĆó ARC Resistance (performance) ŌĆó Hydrolytic Stability (performance) ŌĆó Flexibility (shop handling) ŌĆó Notch Propagation (performance) ŌĆó Smoke Generation (performance) ŌĆó Insulation Weight and Size (performance) ŌĆó Mechanical Toughness (performance + shop handling) ŌĆó Laser Marking (performance + shop handling) Lets see how SEAMLESS has raised the stakes! 22 Nov 2011

- 11. Wet Arc Resistance ŌĆó Reduces collateral damage and PTFE erosion SEAMLESS Standard composite Standard composite 22 Nov 2011

- 12. Hydrolysis Resistance ELONGATION TO BREAK TREND PLOT FOR AGED DUPONT POLYIMIDE FILMS AGING PARAMETERS 200 DEGREES CELSIUS, 100 % RH - PARR BOMB DUPONT HIGH PERFORMANCE MATERIALS JIM HEACOCK - PHIL LACOURT FEBRUARY 2002 100 90 80 70 ELONGATION TO BREAK 60 (%) 50 40 30 20 100HN 10 65T 100T 0 0 5 10 15 20 25 30 35 40 45 50 55 60 AGING TIME (DAYS) 22 Nov 2011

- 13. Flexibility Flexibility (Stiffness & Springback) CW SPI MDC97P0053 2.5 Stiffness (Ounces) 2 1.5 XL-ETFE 1 Composite 0.5 0 /44-22 vs /82-22 /33-26 vs /82-26 Material Tested 22 Nov 2011

- 14. Notch Propagation Notch Propagation Results (Wright Laboratory Report "WL-TR-91-4066") (66% Notch Depth) 100 Cycles to Failure 80 60 XL-ETFE 40 Composite 20 0 /43-22 /43-22 /44-22 /44-22 /33-26 /33-26 /86-22 /86-22 /92-22 /92-22 /82-26 /82-26 NEW AGED NEW AGED NEW AGED 22 Nov 2011

- 15. Temperature Rating ŌĆó Composites 260oC over NPC conductor M22759/80-92 require a Thermal Index test at rated temperature for 10,000 hours as a qualification test 22 Nov 2011

- 16. Smoke Generation Optical Smoke Density (After 20 Minutes) (Wright Laboratory Report "WL-TR-91-4066") 170.3 Optical Smoke Density (Ds) 150 109.7 100 XL-ETFE Composite 50 1.7 1.3 0 /43-22 vs /86-22 /44-22 vs /92-22 22 Nov 2011

- 17. SEAMLESS Advantage: Weight Seamless T Weight Reduction Light Weight Seamless T Weight Reduction (Compared to Tefzel) (Compared to Polyalkene) 12.0% 7.0% 10.0% 6.0% 8.0% 5.0% Percent Percent 6.0% 4.0% 3.0% 4.0% 2.0% 2.0% 1.0% 0.0% 0.0% 6 8 10 12 14 16 18 20 22 24 10 12 14 16 18 20 22 24 Wire Gage Wire Gage THE TAKE AWAY: SEAMLESS weighs between 2 and 10% less than ETFE and 2 to 6% less than polyalkene insulated wires. With a customer BOM an exact weight savings can be calculated. Note: Comparison of Typical Maximum Weights 22 Nov 2011

- 18. SEAMLESS Advantage: Size THE TAKE AWAY: Cross linked ETFE SEAMLESS SEAMLESS requires 15-20% less cross sectional area than Cross Sectional Area Reduction an equivalent ETFE wire bundle; SEAMLESS Composite v. X-Linked ETFE economizing space and increasing 25.0% routing density. 20.0% Looking at a 22 AWG example, 15.0% 24 seamless wires can be routed 10.0% in the same space as an equivalent 5.0% 0.0% 20 wire ETFE bundle. 26 24 22 20 18 16 14 12 10 8 6 4 AWG Size Note: Comparison of Typical Maximum OD 22 Nov 2011

- 19. Mechanical Toughness Dynamic Cut Through Results (Thin Wall) (Wright Laboratory Report "WL-TR-91-4066") 60.0 Cut Through (Pounds) 50.0 M22759/44-22 40.0 (NEW) 30.0 M22759/44-22 (AGED) 20.0 M22759/92-22 10.0 (NEW) 0.0 M22759/92-22 23 70 150 200 (AGED) Temperature (Celsius) 22 Nov 2011

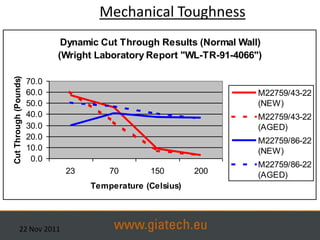

- 20. Mechanical Toughness Dynamic Cut Through Results (Normal Wall) (Wright Laboratory Report "WL-TR-91-4066") Cut Through (Pounds) 70.0 60.0 M22759/43-22 50.0 (NEW) 40.0 M22759/43-22 30.0 (AGED) 20.0 M22759/86-22 10.0 (NEW) 0.0 M22759/86-22 23 70 150 200 (AGED) Temperature (Celsius) 22 Nov 2011

- 21. UV Laser Marking 66% Average contrast on white wire 22 Nov 2011

- 22. SEAMLESS in use The introduction of the Thermax SEAMLESS insulation system has clear advantages over other wire types but what about itŌĆÖs use on the shop floor? 22 Nov 2011

- 23. SEAMLESS Assembly No Edge No Edge No edge lessens the likelihood of catching ŌĆóFaster installation and the robust, tough ŌĆóLess Rework surface is les likely to ŌĆóLess Scrap get scraped, scratched, or damaged THE TAKE AWAY: SEAMLESS pulls easily and seamed ridges do not catch during installation. 22 Nov 2011

- 24. SEAMLESS Advantage: Assembly Standard Composite Technology THE TAKE AWAY: SEAMLESSTechnology SEAMLESS strips cleanly minimizing assembly time 22 Nov 2011

- 25. SEAMLESS Advantage: Construction THERMAX SEAMLESS Competitive Product THE TAKE AWAY: Layer ŌĆōto-layer adhesion eliminates delamination and further improves abrasion resistance. 22 Nov 2011

- 26. Conclusions ŌĆó Composite Construction Solved many Technical Issues ŌĆó Seamless PTFE Technology showed further improvements ŌĆō Reduces Handling and Installation Damage ŌĆō Improves UV markability/contrast. ŌĆō Improves Resistance to Wet Arc Propagation Making SEAMLESS the first choice for Airframe wire today! 22 Nov 2011