Glazing

Download as PPTX, PDF20 likes9,197 views

This document summarizes the process of glazing, which involves fitting lenses into spectacle frames. It discusses the key steps of laying off markings on the lens, lens cutting and edging, and fitting. Lens cutting historically involved manually outlining and chipping lenses, but now is done automatically by edgers. Edging shapes the lens to the frame and creates a bevel. Edging can be done manually with ceramic or diamond wheels or automatically through pattern or patternless edging, where data from a frame tracer is used to directly edge the lens without a pattern. The lens is then fitted into the frame.

1 of 28

Downloaded 70 times

Recommended

High index

High indexvivek parmar

Ã˝

The refractive index is the ratio of the speed of light in a vacuum to the speed of light in a material. Materials with a higher refractive index bend light more and allow for thinner lenses. High index lenses have a refractive index greater than 1.49 for plastics and 1.523 for glass. They provide benefits like thinner and lighter lenses but also have disadvantages like increased chromatic aberration. Common materials used include lanthanum, titanium, and polyurethane.Frame slection

Frame slectionHira Dahal

Ã˝

This document provides guidance on selecting eyeglass frames. It discusses that the primary purposes of frames are to hold lenses to provide optimal vision and be physically comfortable. Additional considerations for frame selection include appearance, fashion, prescription needs, face shape, coloring, nose shape, hairline, image, work environment, habits, budget, and fashion trends. General guidelines are to ensure proper positioning of lenses within the frames based on factors like face shape, width, brow position, and proportion. Color and frame style should complement the face. Frame material and design should account for prescription, activities, and durability needs. Fashion has also become an important factor in frame selection.Tinted lenses

Tinted lensesvivek parmar

Ã˝

This document discusses different types of tinted lenses, including their purposes and materials. It covers integral tints produced during manufacturing by adding metals or metal oxides to glass. Surface coatings deposit metallic oxides onto glass through evaporation. Plastic lenses are dyed by immersing them in organic dyes. Various tint colors like yellow, red, purple, and brown are explained in terms of the materials used and their applications. Integral tints provide consistent tinting while surface coatings and dyes allow tinting of any prescription.Progressive addition lenses

Progressive addition lensesSanjana Chouhan

Ã˝

This document discusses progressive lenses, including their history, types, features, markings, fitting process, advantages, and disadvantages. It provides details on:

- The four main types of lenses - single vision, bifocals, trifocals, and progressive addition lenses.

- Key features of progressive lenses, including having multiple focal points that change continuously across the lens rather than distinct segments.

- Important temporary and permanent markings on progressive lenses used in fitting, including the fitting cross, distance reference circle, and lateral locator lines.

- The process of accurately relocating the fitting cross from temporary to permanent markings to ensure proper positioning over the pupil.Aberration and Ophthalmic Lens Design.ppt

Aberration and Ophthalmic Lens Design.pptJayendra Jha

Ã˝

This document discusses various types of optical aberrations that occur when light passes through lenses and the human eye, including chromatic aberration, spherical aberration, oblique astigmatism, coma, and image distortion. It explains how each aberration leads to imperfect image formation and describes techniques used to reduce their effects, such as using multiple lens elements made of different materials, aspheric surfaces, and the optical properties of the eye itself. The document also provides examples of tests like the duochrome test that evaluate these aberrations during eye exams.Lens form

Lens formOPTOM FASLU MUHAMMED

Ã˝

The document discusses different types of lenses based on their curvature and shape. There are two main types: flat lenses, which have one flat surface, and curved lenses, which have curves on both surfaces. Curved lenses include meniscus lenses, which are convex on the front and concave on the back, and toric lenses, where one surface is spherical and the other toroidal. The total power of a lens is calculated by adding the powers of the front and back surfaces. Lens shape refers to the outline and can include round, oval, pantascopic round oval, and upswept shapes.Aspheric Lenses.pptx

Aspheric Lenses.pptxSalalKhan5

Ã˝

1. Aspheric lenses have at least one surface that is not spherical, changing curvature over the surface rather than maintaining a single radius. This helps correct optical aberrations from off-axis viewing.

2. Early patented aspheric lenses included designs from 1976-1977 and 1980. Aspheric lenses aim to reduce optical aberrations from oblique vision through the lens.

3. Aspheric surfaces are based on conic sections including circles, ellipses, parabolas, and hyperbolas, classified by their p-value in an equation. Higher p-values indicate more oblate ellipses while lower negative values are more hyperbolic.Lens enhancement

Lens enhancementOPTOM FASLU MUHAMMED

Ã˝

The document discusses various lens enhancements that can be applied to spectacle lenses, including anti-reflection coatings, scratch-resistant coatings, UV coatings, and hydrophobic coatings. It provides details on the principles and techniques for applying anti-reflection coatings using single or multiple layers. Hard coatings and their scratch-resistant properties are also covered. Other topics include photochromic lenses that darken in sunlight, tinted lenses, polarizing lenses and their advantages in reducing glare.frame selection.ppt · version 1.ppt

frame selection.ppt · version 1.pptMUHAMMADRASHID311088

Ã˝

The document provides guidance on properly selecting eyeglass frames. It discusses important considerations for frame selection including fitting the frame to the wearer's face shape, prescription needs, and lifestyle. Key factors discussed are proper sizing, positioning, and adjustments to ensure a comfortable and flattering fit. Guidance is given for different facial features, prescriptions, ages, and safety needs to help opticians fit patients with the optimal frame.Dispensing glasses PPT for O.A. 2nd year

Dispensing glasses PPT for O.A. 2nd year Vinitkumar MJ

Ã˝

This document discusses frame and lens selection based on occupation and age. Key factors in frame selection include comfort, appearance, safety, and suitability for the person's occupation and lifestyle. Different occupations require consideration of visual needs, hazards, and working conditions. Frame material, size, and lens material should be chosen accordingly. For example, plastic frames and polycarbonate lenses are recommended for drivers and industrial or sports workers due to safety concerns. Progressive or multifocal lenses may be suitable for various occupations requiring vision at multiple distances.Bifocals PPT

Bifocals PPTMaaz ul haq

Ã˝

Bifocals are lenses with two optical powers, one for distance and one for near. There are several types of bifocal segments including round, flat top, curve top, ribbon, and Franklin style. Bifocals can be made through fused, one piece, or cemented constructions. When measuring for bifocals, the frame is positioned as it will be worn and the bifocal height is measured from the lower limbus or lid margin using a vertical ruler. This ensures the bifocal segment will be at the proper height for the wearer.Ophthalmic lens aberration

Ophthalmic lens aberrationOPTOM FASLU MUHAMMED

Ã˝

1. There are six major lens aberrations that affect image quality through the periphery of the lens, including chromatic aberration, spherical aberration, marginal astigmatism, curvature of field, coma, and distortion.

2. Chromatic aberration occurs because different wavelengths of light focus at different points, producing colored fringes at the periphery, and can be reduced by using higher Abbe value lens materials.

3. Spherical aberration causes peripheral rays to refract more than central rays, slightly blurring the image, while marginal astigmatism introduces astigmatism for obliquely entering light rays.Special purpose frames

Special purpose framesEyenirvaan

Ã˝

This document discusses different types of special purpose frames. It describes frames that hold supplementary lenses outside the main frame, frames that contain cells to hold additional lenses behind the prescription, and folding frames with hinges at the bridge and temples to reduce the frame size. It also covers frames with extensions to support the lower eyelid, trial frames without temples, monocular frames that allow viewing through one lens at a time, and frames with flip-down lenses for reading or sunglasses.Polarized lenses

Polarized lenseskamal thakur

Ã˝

Polarizing lenses reduce glare caused by reflections from surfaces like water, snow, and highways. They work by blocking horizontally polarized light that is reflected from these surfaces, while transmitting regular light. The lenses contain a special filter made of polyvinyl acetate and iodine that absorbs the horizontally vibrating components of light. Polarizing lenses can be made for prescription lenses by mounting the polarizing filter between layers of hard resin or polycarbonate. They provide benefits like reduced driving fatigue and improved visibility for activities like fishing or at the beach.Frame selection

Frame selectionOPTOM FASLU MUHAMMED

Ã˝

The document discusses various factors to consider when selecting eyeglass frames, including facial shape and features. It describes the seven main facial shapes and recommendations for frame styles that complement each shape. Additional details covered include using an existing frame versus a new frame, frame size, weight and color based on facial features, and bridge and temple designs that can shorten, lengthen or narrow the appearance of the nose. Proper fitting of the bridge and pads is also discussed to ensure comfort and support of heavier frames.Bifocal Spectacles..

Bifocal Spectacles..Vishakh Nair

Ã˝

The document describes the various types of bifocals that have been developed over time, including Benjamin Franklin's original design from 1785, solid upcurve bifocals, cemented bifocals, fused Kryptok bifocals, straight top or "D" bifocals, Ultex bifocals, and executive bifocals. Each type is explained in terms of its design, advantages, and disadvantages for the wearer.Best form lenses

Best form lensesvivek parmar

Ã˝

This document discusses different types of best form lenses, which aim to minimize optical aberrations. It describes the history of efforts to improve lens design, dating back to Huygens' proposal in the 17th century. The ideal best form lens is described as being aberration-free, easy to manufacture, and inexpensive. Four main types are covered: aspheric lenses, deep meniscus lenses, lenticular lenses, and periscopic lenses. Aspheric lenses modify the lens curvature to reduce aberrations. Deep meniscus lenses have a base curve of 6.00 diopters or greater. Lenticular lenses have a smaller powered central area within a larger unpowered peripheral frame. Periscopic lenses haveProgressive addition lenses

Progressive addition lensesOPTOM FASLU MUHAMMED

Ã˝

Progressive addition lenses are lenses that gradually change in optical power from the top to the bottom to provide clear vision at all distances without visible lines. They were invented in 1907 and the Varilux 1 was introduced in 1959. Unlike bifocals or trifocals, progressives ensure smooth vision at all distances. The power increase is achieved by gradually decreasing the lens curvature vertically and horizontally. Progressives have advantages over other lenses like continuous vision and no visible lines. Optical design factors like add power, corridor length, and zone widths affect progressives. Proper fitting involves adjusting the frame position and measuring pupil distance and fitting height.Special type of lenses

Special type of lensesOPTOM FASLU MUHAMMED

Ã˝

This document discusses several special types of lenses used in optometry, including lenticular lenses, aniseikonic lenses, aspheric lenses, and Fresnel lenses. Lenticular lenses have a central aperture ground to the needed power surrounded by a peripheral carrier. Aniseikonic lenses address differences in image size between the eyes. Aspheric lenses have non-uniform curvature across the surface to correct aberrations and produce thinner lenses. Fresnel lenses use concentric prismatic sections like lighthouse lenses. High index materials and varifocal lenses are also summarized.Vertex distance

Vertex distanceAl-Shifa College of Paramedical Science,Perinthalmanna

Ã˝

- When a minus lens moves closer to the eye, it becomes stronger, and when it moves farther from the eye, it becomes weaker. Magnification and minification are also affected by vertex distance.

- The vertex compensation formula is used to calculate power changes when a lens moves closer or farther from the eye. The power adjustment is equal to the lens power squared divided by 1000, multiplied by the distance of movement in millimeters.

- The effective power of a lens varies with vertex distance and is calculated as the lens power divided by 1 minus the distance in meters multiplied by the power.Polaroid lenses

Polaroid lensesSwati Panara

Ã˝

Polarized lenses block certain types of light waves to reduce glare. They work by only allowing vertically polarized light to enter the eye, blocking out horizontally polarized light that causes glare when reflected off smooth surfaces like water or roads. Polarized lenses come in various colors and are useful for activities like driving, boating, and photography by improving contrast and reducing eye strain from glare. While effective at reducing most types of glare, polarized lenses have some limitations like not working as well with snow glare and possibly distorting displays.Frame adjustment and quality checking

Frame adjustment and quality checkingOPTOM FASLU MUHAMMED

Ã˝

This document discusses frame adjustment and quality checking. It describes 7 off-face adjustments including x-ing, temple spread, pantoscopic angle, temple fold angle, pad angles, face form, and 4-point touch. It also discusses 7 on-face adjustments including horizontal alignment, vertex distance, frame height, segment height, temple bend, pad contact, and skin/lash clearance. Key details are provided about properly adjusting specific angles and alignments during the fitting process.frenel & rotary prism PART 2.pptx

frenel & rotary prism PART 2.pptxAl-Shifa College of Paramedical Science,Perinthalmanna

Ã˝

Fresnel prisms are thin, lightweight prisms that can be applied to existing spectacle lenses. They are used diagnostically to measure eye alignment and fusional reserves, and therapeutically to relieve diplopia from conditions like convergence insufficiency or small eye turnings. Fresnel prisms have advantages of thinness and flexibility but cause some visual acuity loss with higher powers. Risley prisms are a combination of two prisms that can be rotated to provide variable amounts of combined horizontal and vertical prismatic correction.Bifocal lenses: types and principles

Bifocal lenses: types and principlesGarima Poudel

Ã˝

Bifocal lenses have two optical powers, one for distance vision and one for near vision. They are useful for presbyopia. There are several types of bifocal lenses including round, flat-top, and executive styles. Benjamin Franklin is credited with inventing the first bifocal lens in the late 18th century by cutting a single lens in half. Modern bifocals are manufactured using various techniques like fusing, cementing, or making from a single piece of plastic or glass. Proper positioning and design of the near segment is important to reduce issues like image jump and chromatic aberration. Bifocals come in many styles and materials to best suit individual needs and prescription requirements.Aspheric lenses

Aspheric lensesvivek parmar

Ã˝

This document discusses aspheric lenses. It begins with a brief history of aspheric lens development from 1909 to 1980. It then covers terminology, the introduction of aspheric lenses which aim to reduce optical aberrations compared to spherical lenses. The document discusses various aspheric lens designs and how they can reduce peripheral aberrations and make lenses thinner. It also covers measuring aspheric lenses, uses of aspheric lenses, and benefits such as reduction of oblique astigmatism and thinner lens designs.Frame measurementsand markings

Frame measurementsand markingsOPTOM FASLU MUHAMMED

Ã˝

Frame measurements are essential for ordering prescription glasses correctly. The boxing system uses geometric center, lens size (eye size A), depth (B), and width (C) in millimeters. Distance between lenses (DBL) and geometric center distance (GCD) are also in millimeters. Temple length is overall length from center barrel to end. Frames are marked with eye size, DBL, temple length, manufacturer, and country of origin. Safety frames are marked with "Z87". Metal frames indicate gold content in karats.Frames:types, materials and designs

Frames:types, materials and designsRaju Kaiti

Ã˝

Frame parts, constructions, materials, bridges, temples, frame fronts, shields, end piece, cellulose acetate, nickel, optyl, gold filled, titanium, aluminium,

Decentration and prismatic effect in lens (1)

Decentration and prismatic effect in lens (1)Sachitanand Singh

Ã˝

Decentration of lenses can induce unwanted prism. The amount of induced prism depends on the distance of decentration from the optical center and the power of the lens. For plus lenses, the base of the induced prism is in the direction of decentration, while for minus lenses it is in the opposite direction. Prism power can be calculated using Prentice's rule. The induced prism from decentration can have effects on binocular vision and eye alignment. Careful centration of lenses is important for optimal vision and comfort.3gearandthreadmanufacturing-181227105343.pdf

3gearandthreadmanufacturing-181227105343.pdfveeramaniveltraining

Ã˝

The document discusses various methods for manufacturing gears and threads. It describes casting, metal forming, powder metallurgy, and metal removal as common methods for making gears. Metal forming techniques include roll forming, extrusion, stamping, and coining. Metal removal techniques involve gear cutting, shaping, planing, hobbing, and broaching. The document also outlines various threading manufacturing methods such as lathe cutting, chasing, die threading, tapping, milling, rolling, grinding, casting, and whirling.gear and thread manufacturing,metal cutting,manufacturing processes,Productio...

gear and thread manufacturing,metal cutting,manufacturing processes,Productio...Prof.Mayur Modi

Ã˝

The document discusses various methods for manufacturing gears and threads. It describes casting, metal forming, powder metallurgy, and metal removal as common methods for making gears. Metal forming techniques include roll forming, extrusion, stamping, and coining. Metal removal techniques involve gear cutting, shaping, planing, hobbing, and broaching. The document also outlines various threading manufacturing methods such as lathe cutting, chasing, die threading, tapping, milling, rolling, grinding, casting, and whirling.More Related Content

What's hot (20)

frame selection.ppt · version 1.ppt

frame selection.ppt · version 1.pptMUHAMMADRASHID311088

Ã˝

The document provides guidance on properly selecting eyeglass frames. It discusses important considerations for frame selection including fitting the frame to the wearer's face shape, prescription needs, and lifestyle. Key factors discussed are proper sizing, positioning, and adjustments to ensure a comfortable and flattering fit. Guidance is given for different facial features, prescriptions, ages, and safety needs to help opticians fit patients with the optimal frame.Dispensing glasses PPT for O.A. 2nd year

Dispensing glasses PPT for O.A. 2nd year Vinitkumar MJ

Ã˝

This document discusses frame and lens selection based on occupation and age. Key factors in frame selection include comfort, appearance, safety, and suitability for the person's occupation and lifestyle. Different occupations require consideration of visual needs, hazards, and working conditions. Frame material, size, and lens material should be chosen accordingly. For example, plastic frames and polycarbonate lenses are recommended for drivers and industrial or sports workers due to safety concerns. Progressive or multifocal lenses may be suitable for various occupations requiring vision at multiple distances.Bifocals PPT

Bifocals PPTMaaz ul haq

Ã˝

Bifocals are lenses with two optical powers, one for distance and one for near. There are several types of bifocal segments including round, flat top, curve top, ribbon, and Franklin style. Bifocals can be made through fused, one piece, or cemented constructions. When measuring for bifocals, the frame is positioned as it will be worn and the bifocal height is measured from the lower limbus or lid margin using a vertical ruler. This ensures the bifocal segment will be at the proper height for the wearer.Ophthalmic lens aberration

Ophthalmic lens aberrationOPTOM FASLU MUHAMMED

Ã˝

1. There are six major lens aberrations that affect image quality through the periphery of the lens, including chromatic aberration, spherical aberration, marginal astigmatism, curvature of field, coma, and distortion.

2. Chromatic aberration occurs because different wavelengths of light focus at different points, producing colored fringes at the periphery, and can be reduced by using higher Abbe value lens materials.

3. Spherical aberration causes peripheral rays to refract more than central rays, slightly blurring the image, while marginal astigmatism introduces astigmatism for obliquely entering light rays.Special purpose frames

Special purpose framesEyenirvaan

Ã˝

This document discusses different types of special purpose frames. It describes frames that hold supplementary lenses outside the main frame, frames that contain cells to hold additional lenses behind the prescription, and folding frames with hinges at the bridge and temples to reduce the frame size. It also covers frames with extensions to support the lower eyelid, trial frames without temples, monocular frames that allow viewing through one lens at a time, and frames with flip-down lenses for reading or sunglasses.Polarized lenses

Polarized lenseskamal thakur

Ã˝

Polarizing lenses reduce glare caused by reflections from surfaces like water, snow, and highways. They work by blocking horizontally polarized light that is reflected from these surfaces, while transmitting regular light. The lenses contain a special filter made of polyvinyl acetate and iodine that absorbs the horizontally vibrating components of light. Polarizing lenses can be made for prescription lenses by mounting the polarizing filter between layers of hard resin or polycarbonate. They provide benefits like reduced driving fatigue and improved visibility for activities like fishing or at the beach.Frame selection

Frame selectionOPTOM FASLU MUHAMMED

Ã˝

The document discusses various factors to consider when selecting eyeglass frames, including facial shape and features. It describes the seven main facial shapes and recommendations for frame styles that complement each shape. Additional details covered include using an existing frame versus a new frame, frame size, weight and color based on facial features, and bridge and temple designs that can shorten, lengthen or narrow the appearance of the nose. Proper fitting of the bridge and pads is also discussed to ensure comfort and support of heavier frames.Bifocal Spectacles..

Bifocal Spectacles..Vishakh Nair

Ã˝

The document describes the various types of bifocals that have been developed over time, including Benjamin Franklin's original design from 1785, solid upcurve bifocals, cemented bifocals, fused Kryptok bifocals, straight top or "D" bifocals, Ultex bifocals, and executive bifocals. Each type is explained in terms of its design, advantages, and disadvantages for the wearer.Best form lenses

Best form lensesvivek parmar

Ã˝

This document discusses different types of best form lenses, which aim to minimize optical aberrations. It describes the history of efforts to improve lens design, dating back to Huygens' proposal in the 17th century. The ideal best form lens is described as being aberration-free, easy to manufacture, and inexpensive. Four main types are covered: aspheric lenses, deep meniscus lenses, lenticular lenses, and periscopic lenses. Aspheric lenses modify the lens curvature to reduce aberrations. Deep meniscus lenses have a base curve of 6.00 diopters or greater. Lenticular lenses have a smaller powered central area within a larger unpowered peripheral frame. Periscopic lenses haveProgressive addition lenses

Progressive addition lensesOPTOM FASLU MUHAMMED

Ã˝

Progressive addition lenses are lenses that gradually change in optical power from the top to the bottom to provide clear vision at all distances without visible lines. They were invented in 1907 and the Varilux 1 was introduced in 1959. Unlike bifocals or trifocals, progressives ensure smooth vision at all distances. The power increase is achieved by gradually decreasing the lens curvature vertically and horizontally. Progressives have advantages over other lenses like continuous vision and no visible lines. Optical design factors like add power, corridor length, and zone widths affect progressives. Proper fitting involves adjusting the frame position and measuring pupil distance and fitting height.Special type of lenses

Special type of lensesOPTOM FASLU MUHAMMED

Ã˝

This document discusses several special types of lenses used in optometry, including lenticular lenses, aniseikonic lenses, aspheric lenses, and Fresnel lenses. Lenticular lenses have a central aperture ground to the needed power surrounded by a peripheral carrier. Aniseikonic lenses address differences in image size between the eyes. Aspheric lenses have non-uniform curvature across the surface to correct aberrations and produce thinner lenses. Fresnel lenses use concentric prismatic sections like lighthouse lenses. High index materials and varifocal lenses are also summarized.Vertex distance

Vertex distanceAl-Shifa College of Paramedical Science,Perinthalmanna

Ã˝

- When a minus lens moves closer to the eye, it becomes stronger, and when it moves farther from the eye, it becomes weaker. Magnification and minification are also affected by vertex distance.

- The vertex compensation formula is used to calculate power changes when a lens moves closer or farther from the eye. The power adjustment is equal to the lens power squared divided by 1000, multiplied by the distance of movement in millimeters.

- The effective power of a lens varies with vertex distance and is calculated as the lens power divided by 1 minus the distance in meters multiplied by the power.Polaroid lenses

Polaroid lensesSwati Panara

Ã˝

Polarized lenses block certain types of light waves to reduce glare. They work by only allowing vertically polarized light to enter the eye, blocking out horizontally polarized light that causes glare when reflected off smooth surfaces like water or roads. Polarized lenses come in various colors and are useful for activities like driving, boating, and photography by improving contrast and reducing eye strain from glare. While effective at reducing most types of glare, polarized lenses have some limitations like not working as well with snow glare and possibly distorting displays.Frame adjustment and quality checking

Frame adjustment and quality checkingOPTOM FASLU MUHAMMED

Ã˝

This document discusses frame adjustment and quality checking. It describes 7 off-face adjustments including x-ing, temple spread, pantoscopic angle, temple fold angle, pad angles, face form, and 4-point touch. It also discusses 7 on-face adjustments including horizontal alignment, vertex distance, frame height, segment height, temple bend, pad contact, and skin/lash clearance. Key details are provided about properly adjusting specific angles and alignments during the fitting process.frenel & rotary prism PART 2.pptx

frenel & rotary prism PART 2.pptxAl-Shifa College of Paramedical Science,Perinthalmanna

Ã˝

Fresnel prisms are thin, lightweight prisms that can be applied to existing spectacle lenses. They are used diagnostically to measure eye alignment and fusional reserves, and therapeutically to relieve diplopia from conditions like convergence insufficiency or small eye turnings. Fresnel prisms have advantages of thinness and flexibility but cause some visual acuity loss with higher powers. Risley prisms are a combination of two prisms that can be rotated to provide variable amounts of combined horizontal and vertical prismatic correction.Bifocal lenses: types and principles

Bifocal lenses: types and principlesGarima Poudel

Ã˝

Bifocal lenses have two optical powers, one for distance vision and one for near vision. They are useful for presbyopia. There are several types of bifocal lenses including round, flat-top, and executive styles. Benjamin Franklin is credited with inventing the first bifocal lens in the late 18th century by cutting a single lens in half. Modern bifocals are manufactured using various techniques like fusing, cementing, or making from a single piece of plastic or glass. Proper positioning and design of the near segment is important to reduce issues like image jump and chromatic aberration. Bifocals come in many styles and materials to best suit individual needs and prescription requirements.Aspheric lenses

Aspheric lensesvivek parmar

Ã˝

This document discusses aspheric lenses. It begins with a brief history of aspheric lens development from 1909 to 1980. It then covers terminology, the introduction of aspheric lenses which aim to reduce optical aberrations compared to spherical lenses. The document discusses various aspheric lens designs and how they can reduce peripheral aberrations and make lenses thinner. It also covers measuring aspheric lenses, uses of aspheric lenses, and benefits such as reduction of oblique astigmatism and thinner lens designs.Frame measurementsand markings

Frame measurementsand markingsOPTOM FASLU MUHAMMED

Ã˝

Frame measurements are essential for ordering prescription glasses correctly. The boxing system uses geometric center, lens size (eye size A), depth (B), and width (C) in millimeters. Distance between lenses (DBL) and geometric center distance (GCD) are also in millimeters. Temple length is overall length from center barrel to end. Frames are marked with eye size, DBL, temple length, manufacturer, and country of origin. Safety frames are marked with "Z87". Metal frames indicate gold content in karats.Frames:types, materials and designs

Frames:types, materials and designsRaju Kaiti

Ã˝

Frame parts, constructions, materials, bridges, temples, frame fronts, shields, end piece, cellulose acetate, nickel, optyl, gold filled, titanium, aluminium,

Decentration and prismatic effect in lens (1)

Decentration and prismatic effect in lens (1)Sachitanand Singh

Ã˝

Decentration of lenses can induce unwanted prism. The amount of induced prism depends on the distance of decentration from the optical center and the power of the lens. For plus lenses, the base of the induced prism is in the direction of decentration, while for minus lenses it is in the opposite direction. Prism power can be calculated using Prentice's rule. The induced prism from decentration can have effects on binocular vision and eye alignment. Careful centration of lenses is important for optimal vision and comfort.Similar to Glazing (20)

3gearandthreadmanufacturing-181227105343.pdf

3gearandthreadmanufacturing-181227105343.pdfveeramaniveltraining

Ã˝

The document discusses various methods for manufacturing gears and threads. It describes casting, metal forming, powder metallurgy, and metal removal as common methods for making gears. Metal forming techniques include roll forming, extrusion, stamping, and coining. Metal removal techniques involve gear cutting, shaping, planing, hobbing, and broaching. The document also outlines various threading manufacturing methods such as lathe cutting, chasing, die threading, tapping, milling, rolling, grinding, casting, and whirling.gear and thread manufacturing,metal cutting,manufacturing processes,Productio...

gear and thread manufacturing,metal cutting,manufacturing processes,Productio...Prof.Mayur Modi

Ã˝

The document discusses various methods for manufacturing gears and threads. It describes casting, metal forming, powder metallurgy, and metal removal as common methods for making gears. Metal forming techniques include roll forming, extrusion, stamping, and coining. Metal removal techniques involve gear cutting, shaping, planing, hobbing, and broaching. The document also outlines various threading manufacturing methods such as lathe cutting, chasing, die threading, tapping, milling, rolling, grinding, casting, and whirling.bifocals-210520085134.pdf

bifocals-210520085134.pdfMUHAMMADRASHID311088

Ã˝

Bifocals are lenses with two optical powers, one for distance and one for near. There are several types of bifocal segments including round, flat top, curve top, ribbon, and Franklin style. Bifocals can be made through fused, one-piece, or cemented constructions. When measuring for bifocals, the frame is positioned as it will be worn and the bifocal height is measured from the lower limbus or lid margin using a vertical ruler. This ensures the bifocal segment will be at the proper height for the wearer.Optics and design of soft contact lens.pptx

Optics and design of soft contact lens.pptxAshi Lakher

Ã˝

This document provides an overview of optics and design considerations for soft contact lenses. It discusses basics of contact lens optics, various optical properties including effectiveness, magnification, accommodation, convergence, and aberrations. It also covers lens design parameters such as diameter, base curve, thickness, and material properties. Design factors like surface curvature, edge design, and aspheric lenses are summarized. The key points are that soft lens design optimizes vision, comfort and safety by conforming to the cornea while meeting oxygen requirements through material and thickness choices.MT-II UNIT II TURNING

MT-II UNIT II TURNING Karthik R

Ã˝

Centre lathe, constructional features, specification, operations – taper turning methods, thread cutting methods, special attachments, machining time and power estimation. Capstan and turret lathes- tool layout – automatic lathes: semi automatic – single spindle : Swiss type, automatic screw type – multi spindle:CENTRE LATHE AND SPECIAL PURPOSE LATHES.ppt

CENTRE LATHE AND SPECIAL PURPOSE LATHES.pptDineshKumar4165

Ã˝

Centre lathe, constructional features, various operations and specifications, taper turning methods, thread cutting methods, special attachments, machining time and power estimation. Capstan and turret lathes – Automatic lathe: single spindle, swiss type, screw type, multi spindle - Turret Indexing mechanism - Bar feed mechanismMp iii lab

Mp iii labSathia Prathap

Ã˝

The document describes various manufacturing processes including foundry, gear cutting, and tool grinding. In foundry, it discusses mould preparation using solid and split patterns. For gear cutting, it explains gear hobbing and spur gear milling processes. It provides steps to make moulds and cut gears. It also provides specifications of a gear hobbing machine.Optical measuring instruments

Optical measuring instrumentsnmahi96

Ã˝

The document discusses various optical measuring instruments. It describes the engineering microscope, which provides an enlarged view of small objects to measure dimensions. It also describes the toolmakers microscope in detail. The toolmakers microscope uses optics and has a base, worktable, optical head, and ground glass screen to project and measure contours, diameters, distances between holes, and other geometric features of parts. Interference patterns created using an optical flat allow for measuring the flatness and parallelism of surfaces. Other optical measuring instruments discussed include the optical projector, interferometers like the Michelson interferometer, and sources of light used for optical measurements.Form measurement

Form measurementMohd Erfy Ismail

Ã˝

This document provides information on measuring various geometric features of screw threads and gears. It discusses measuring the major diameter, minor diameter, pitch, and other elements of threads using instruments like micrometers, thread gauges, and comparators. For gears, it describes measuring runout, pitch, profile, backlash, tooth thickness, and alignment using devices like dial indicators, involute measuring machines, and angular measurement techniques. The document also defines common terminology for screw thread and gear geometry.The Basics of Thread Rolling

The Basics of Thread RollingLiberato Pietrantoni

Ã˝

The document discusses thread rolling, including its benefits over cutting threads, material considerations, design factors, and tooling techniques. Thread rolling strengthens materials without metal cutting and allows for lower costs, faster production, and superior thread quality compared to cutting. The formability of different materials impacts thread finish and die life. Designing the blank diameter, chamfer angle, and thread/roll length properly optimizes the rolling process. A variety of tooling techniques like in-feed dies and skewed roll axes can be used to roll internal and external threads of different lengths and pitches.Milling & Gear Cutting

Milling & Gear CuttingKonal Singh

Ã˝

MILLING – Cutting parameters, machine time calculation

Milling operation – Plain milling, side & face milling, form milling, gang milling, end milling, face milling, T slot milling, slitting

GEAR CUTTING – Gear cutting on milling machine – dividing head and indexing method, gear hobbing, principle of operation, advantages & limitation, hobbing tech, gear shaping, gear finishing processMachining operations and machine tools

Machining operations and machine toolsMuhammad Muddassir

Ã˝

Fundamentals of Metal cutting and Machining Processes

MACHINING OPERATIONS AND MACHINING TOOLS

Turning and Related Operations

Drilling and Related Operations

Milling

Machining Centers and Turning Centers

Other Machining Operations

High Speed Machining

Dispencing optics

Dispencing opticsMahantesh B

Ã˝

The document provides an overview of optical dispensing. It discusses defining optical dispensing and the steps involved, including frame selection based on facial shape, frame measurements, lens measurements, counseling patients on lens materials and coatings, and the process of fitting lenses into frames which involves marking, cutting, and edging lenses.Unit 4B Thread Manufacturing

Unit 4B Thread ManufacturingMechbytes

Ã˝

Thread Manufacturing methods covering thread casting, thread rolling, thread cutting on lathe, thread grinding, thread whirling, thread milling, thread rolling etcScrew thread measurement

Screw thread measurementChintan Mehta

Ã˝

This document discusses methods for measuring various elements of screw threads, including major diameter, minor diameter, effective diameter or pitch diameter, pitch, flank angle, and thread form. Common measurement tools mentioned include micrometers, thread comparators, thread micrometers, tool makers microscopes, and optical projection. Methods like using setting gauges, V-pieces, taper parallels, rollers and slip gauges, and one-, two-, or three-wire techniques are described for different thread measurements.Manufacturing methods of soft contact lens - presentation at www.eyenirvaan.com

Manufacturing methods of soft contact lens - presentation at www.eyenirvaan.comEyenirvaan

Ã˝

There are four main methods for manufacturing soft contact lenses: spin casting, lathe cutting, cast molding, and lightstream process. Spin casting involves injecting liquid polymer into a spinning mold to form the lens shape and curing it with UV light. Lathe cutting machines individually grind and polish acrylic buttons into lenses. Cast molding injects liquid monomer into molds that are then cured to form a finished lens. The lightstream process uses molds and masks to form the lens edges during curing. Each method has advantages and disadvantages related to precision, reproducibility, and cost.Evaluation of 3D-Projection Image Capture

Evaluation of 3D-Projection Image CaptureBurns Digital Imaging LLC

Ã˝

It is now common practice to monitor imaging performance prior to, and during, image acquisition. While these methods have been applied to near-flat objects and documents, less attention has been given to developing reliable methods for two-dimensional perspective images, where optical depth-of-field can be critical. we describe results of our effort to adapt standard methods to this new application. Cameras using simple, fixed lens and a tilted lens were evaluated.Assemblies.ppt

Assemblies.pptSamuelSunbai

Ã˝

The document provides guidance on creating assembly drawings and interpreting machine drawings. It discusses exploring product assemblies by investigating individual parts, functions, materials, and fastening techniques. Key points include representing assembled products through 3D CAD models after understanding individual parts. Assembly drawings should show all components in functional position and how they fit together using views and sections. machining and machine tool (Types of milling machine)

machining and machine tool (Types of milling machine)alakshendra pratap singh

Ã˝

The document discusses milling machines, including their basic functions, classifications, working principles, and applications. Milling machines are used to produce flat and inclined surfaces as well as special contours. They are classified based on their purpose, configuration, spindle orientation, and level of automation. Common milling cutter types include plain, side, end, and face cutters. Form cutters are also used to machine complex 2D and 3D contours. Milling machines have a variety of applications in machining flat surfaces, slots, threads, and other features.Recently uploaded (20)

Meeting the needs of modern students?, Selina McCoy

Meeting the needs of modern students?, Selina McCoyEconomic and Social Research Institute

Ã˝

NAPD Annual Symposium

“Equity in our Schools: Does the system deliver for all young people?”NUTRITIONAL ASSESSMENT AND EDUCATION - 5TH SEM.pdf

NUTRITIONAL ASSESSMENT AND EDUCATION - 5TH SEM.pdfDolisha Warbi

Ã˝

NUTRITIONAL ASSESSMENT AND EDUCATION, Introduction, definition, types - macronutrient and micronutrient, food pyramid, meal planning, nutritional assessment of individual, family and community by using appropriate method, nutrition education, nutritional rehabilitation, nutritional deficiency disorder, law/policies regarding nutrition in India, food hygiene, food fortification, food handling and storage, food preservation, food preparation, food purchase, food consumption, food borne diseases, food poisoningHow to Configure Proforma Invoice in Odoo 18 Sales

How to Configure Proforma Invoice in Odoo 18 SalesCeline George

Ã˝

In this slide, we’ll discuss on how to configure proforma invoice in Odoo 18 Sales module. A proforma invoice is a preliminary invoice that serves as a commercial document issued by a seller to a buyer.How to create security group category in Odoo 17

How to create security group category in Odoo 17Celine George

Ã˝

This slide will represent the creation of security group category in odoo 17. Security groups are essential for managing user access and permissions across different modules. Creating a security group category helps to organize related user groups and streamline permission settings within a specific module or functionality.ITI Turner Question Paper MCQ E-Book Free Download

ITI Turner Question Paper MCQ E-Book Free DownloadSONU HEETSON

Ã˝

ITI Turner Question Paper MCQ Book PDF Free Download. All Questions collected from NIMI Mock Test, CTS Bharat Skills Question Bank, Previous Exam papers. Helpful for CTS Trade Theory 1st & 2nd Year CBT Exam,Ã˝Apprentice test, AITT, ISRO, DRDO, NAVY, ARMY, Naval Dockyard, Tradesman, Training Officer, Instructor, RRB ALP CBT 2,Ã˝Railway Technician, CEPTAM, BRO, PWD, PHED, Air India, BHEL, BARC, IPSC, CISF, CTI, HSFC, GSRTC, GAIL, PSC, Viva, Tests, QuizÃ˝& all other technical competitive exams.Unit 1 Computer Hardware for Educational Computing.pptx

Unit 1 Computer Hardware for Educational Computing.pptxRomaSmart1

Ã˝

Computers have revolutionized various sectors, including education, by enhancing learning experiences and making information more accessible. This presentation, "Computer Hardware for Educational Computing," introduces the fundamental aspects of computers, including their definition, characteristics, classification, and significance in the educational domain. Understanding these concepts helps educators and students leverage technology for more effective learning.ASP.NET Web API Interview Questions By Scholarhat

ASP.NET Web API Interview Questions By ScholarhatScholarhat

Ã˝

ASP.NET Web API Interview Questions By ScholarhatRest API Interview Questions PDF By ScholarHat

Rest API Interview Questions PDF By ScholarHatScholarhat

Ã˝

Rest API Interview Questions PDF By ScholarHatGRADE-1-QUARTER 4-MATHEMATICS-WEEK-3.pptx

GRADE-1-QUARTER 4-MATHEMATICS-WEEK-3.pptxAngellieMaeDoce

Ã˝

math-matatag curriculum

quarter 4

week 3

grade 1Azure Solution Architect Interview Questions By ScholarHat

Azure Solution Architect Interview Questions By ScholarHatScholarhat

Ã˝

Azure Solution Architect Interview Questions By ScholarHatFull-Stack .NET Developer Interview Questions PDF By ScholarHat

Full-Stack .NET Developer Interview Questions PDF By ScholarHatScholarhat

Ã˝

Full-Stack .NET Developer Interview Questions PDF By ScholarHatYear 10 The Senior Phase Session 3 Term 1.pptx

Year 10 The Senior Phase Session 3 Term 1.pptxmansk2

Ã˝

Year 10 The Senior Phase Session 3 Term 1.pptxGlazing

- 1. GLAZING - BY Happy patel & Payal sangani

- 2. Process of fitting lenses into a spectacle frame…..

- 3. glazing • Laying off • Lens cutting • Lens edging • fitting

- 4. Laying off • Before a lens can be edged, • marking of cyl axis pd lens size,according to frame etc. should be marked in the correct position relative to the lens shape & specific individual Rx by using….

- 6. Lens cutting & chipping • In the past lens cutting & chipping process involved • Glass cutter: that outlining the desired lens shape on the glass with an appropriate marking • The lens was cut several mm larger than required,for some inaccuracy in chipping the lens & lens edge finish • After lens cutting,outermost areas of glass were removed using chipping pliers • This is done only in manual edging process,in the automatic edger,the full lens is edged to the required shape

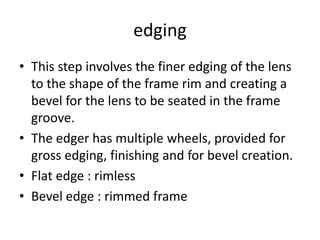

- 7. edging • This step involves the finer edging of the lens to the shape of the frame rim and creating a bevel for the lens to be seated in the frame groove. • The edger has multiple wheels, provided for gross edging, finishing and for bevel creation. • Flat edge : rimless • Bevel edge : rimmed frame

- 8. • To converting an uncut lens to the desired lens shape Edging manual auto pattern Pattern less

- 9. Manual:hand edging • Types of hand edger - ceramic wheel - diamond wheel • Now days more useful for: - edge smotthing - reducing a lens size - reshaping the len

- 10. Manual edging

- 12. AUTO EDGING • Pattern Edgeing: (semi auto) Information from the pattern edger shape is used to cut out. This pattern is then run along a sensor, the data from which, is used by the edger to edge the lens • Patternless Edgers: (fully auto) information from the frame scanner/tracer is transferred directly to the edging machine, which edges the lens accordingly

- 13. Pattern/edging former • For converting an uncut lens to the desired shape is by the use of former/pattern. • Made from flat plastic material or metal plate • It is held in position by holes to determine the horizontal line of shape& standard oc position • Available in according different eyesize

- 14. Pattern Edger

- 15. Pattern Measurements and Terminology • mechanical center: of a pattern is the point on the pattern around which the pattern rotates. - The mechanical center is easy to find since it is found in the middle of the large hole in the pattern • Pattern Making : Because of the vast number of available frame styles, it is impossible to have a complete library of patterns -36.5 mm standard size - to prevent pattern distortion,the pattern made larger

- 16. Pattern Edging

- 18. Pattern less

- 19. Steps & facilities • Electronic shape • Required lens and frame materials as a option • Patternless edging viewing screen - that shows lens shape -show the edge of the lens • Lens drilling as an option • Self-calibration & decentration calculation – because tracer knows dbl & pd

- 20. Electronic shape by frame tracer

- 21. Frame tracer

- 22. measurements about lens size,dbl,pd etc.

- 23. Required lens and frame materials as a option

- 25. Patternless edging viewing screen

- 27. Lens fitting • lens is inserted into the frame. • SPRINGING IN : insertation of the lens in rimmed frame • RIMLESS FITTING : insertation of the lens in rimless frame

- 28. REFRENCE :