Gold

- 1. Material & Processes Kehaan J Saraiya

- 2. Gold.

- 3. Properties of gold • Five ten – millionths of the earths outer layer. • Said to have formed due to a supernova nucleosynthesis. • Its heavy - 19 x water 2 x lead if we had enough gold to fill a one litre milk carton, it would weigh 19.3 Kg • Gold is quite soft – slightly harder than finger nails • Very malleable and ductile. • Melting point – 1060 c • Boiling point – 2660 c • Atomic mass – 196.97

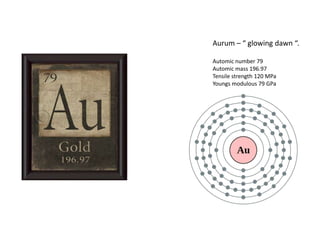

- 4. Aurum – “ glowing dawn “. Automic number 79 Automic mass 196.97 Tensile strength 120 MPa Youngs modulous 79 GPa

- 5. Why gold ? • Esthetic beauty – high luster. • High malleability and ductility. • Soft • Rare and high appreciation value.

- 6. Other products / uses • Jewelry • Dentistry • Therapeutic • Cosmetic • electronics

- 11. Alternative • White gold alloys – based on palladium silver & other white metal.

- 12. Impact of gold. • Environmental Impacts:

Poisoned Waters

Solid Waste

Polluted Air

Threatened Natural Areas • Community Impacts:

Endangered Communities

Disadvantaged Women

Violated Human Rights

Toll on Indigenous Peoples • Worker Impacts:

A Dangerous Profession

Undermined Workers' Rights • Economic Impacts:

Economic and Financial Toll

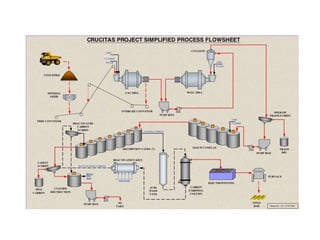

- 15. • Comminution is the breaking up of ore to make gold available for treatment. Conventionally, this process occurs in multi-stage crushing and milling circuits. Modern technology is based on large mills fed directly with run-of-mine material. • Gold ores can typically be classified into: • refractory ores, where the gold is locked within a sulphide mineral and not readily available for recovery by the cyanidation process; or • free milling, where the gold is readily available for recovery by the cyanidation process. • Refractory ore treatment – after fine grinding, the sulphide materials are floated away from the barren gangue material to produce a high-grade sulphide concentrate. The sulphide concentrate is oxidised by either roasting as at AngloGold Ashanti Mineração or bacterial oxidation (BIOX) as at Obuasi. The oxidation process oxidises the sulphide minerals liberating the gold particles making them amenable to recovery by the cyanidation process.

- 16. • Free milling and oxidised refractory ores are processed for gold recovery by agitator leaching the ore in an alkaline cyanide leach solution followed generally by adsorption of the gold cyanide complex onto activated carbon-in-pulp (CIP). • The alternative process is the heap-leach process. Generally considered applicable to only high-tonnage, low-grade ore deposits, AngloGold Ashanti has successfully applied this to medium-grade deposits where the ore deposit tonnage cannot economically justify constructing a process plant. Here, the run-of-mine ore is crushed and placed on the leach pad. Low strength alkaline cyanide solution is applied, generally as a drip, to the top of the heap for periods of up to three months. The dissolved gold bearing solution is collected from the base of the heap and transferred to the carbon-in-solution (CIS) columns where the gold cyanide complex is adsorbed onto activated carbon. The stripped solution is recycled back to the top of the heaps. • Gold adsorbed onto activated carbon is recovered by a process of re-dissolving the gold from the activated carbon (elution), followed by precipitation in electro- winning cells and subsequent smelting of that precipitate into doré bars that are shipped to the gold refineries.

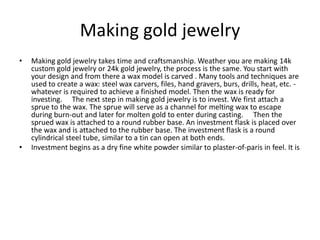

- 17. Making gold jewelry • Making gold jewelry takes time and craftsmanship. Weather you are making 14k custom gold jewelry or 24k gold jewelry, the process is the same. You start with your design and from there a wax model is carved . Many tools and techniques are used to create a wax: steel wax carvers, files, hand gravers, burs, drills, heat, etc. - whatever is required to achieve a finished model. Then the wax is ready for investing.

The next step in making gold jewelry is to invest. We first attach a sprue to the wax. The sprue will serve as a channel for melting wax to escape during burn-out and later for molten gold to enter during casting.

Then the sprued wax is attached to a round rubber base. An investment flask is placed over the wax and is attached to the rubber base. The investment flask is a round cylindrical steel tube, similar to a tin can open at both ends. • Investment begins as a dry fine white powder similar to plaster-of-paris in feel. It is

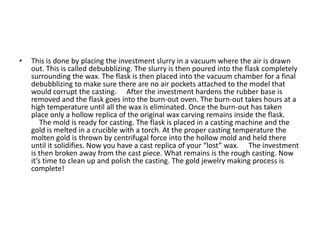

- 18. • This is done by placing the investment slurry in a vacuum where the air is drawn out. This is called debubblizing. The slurry is then poured into the flask completely surrounding the wax. The flask is then placed into the vacuum chamber for a final debubblizing to make sure there are no air pockets attached to the model that would corrupt the casting.

After the investment hardens the rubber base is removed and the flask goes into the burn-out oven. The burn-out takes hours at a high temperature until all the wax is eliminated. Once the burn-out has taken place only a hollow replica of the original wax carving remains inside the flask.

The mold is ready for casting. The flask is placed in a casting machine and the gold is melted in a crucible with a torch. At the proper casting temperature the molten gold is thrown by centrifugal force into the hollow mold and held there until it solidifies. Now you have a cast replica of your “lost” wax.

The investment is then broken away from the cast piece. What remains is the rough casting. Now it’s time to clean up and polish the casting. The gold jewelry making process is complete!

- 20. videos • making gold jewelry • investment casting • Chain making

- 22. The price of gold fluctuates according to the demand of the buyers and the amount being sold by the sellers. The term carat in 24K gold refers to the amount of base metals mixed in the alloy.. 24K being the purest form.

- 23. Thank you.