PPT ON GREEN CONCRETE BY TANMAY KUMAR

- 1. Submitted by:- Tanmay Kumar Das Civil Engineering BBIT

- 2. CONTENT 1.What is Green Concrete ? 2.Whygreen concrete 3. Materials for Green Concrete 4. bonding betweensteelbars andlightweight 5.Cementitious materials - FlyAsh 6.SUITABILITYOF GREENCONCRETEIN STRUCTURES 7.APPLICATIONOF GREENCONCRETE 8.Advantage Of Green Concrete 9.LIMITATION 10.SCOPE IN INDIA 11.CONCLUSION 12.REFERENCE

- 3. What is Green Concrete ? A concrete that made with concrete waste and uses less energy in its production & produces less carbon dioxide than normal concrete.. This is called eco-friendly and reduced environmental impact for e.g. Energy saving ,co2 emissions, waste water.

- 4. Why Green Concrete ? ’ā╝ The main ingredient in concrete is cement and it consists of Limestone (Calcium Carbonate CaCO3). ’ā╝ During manufacture of cement, its ingredients are heated to about 800 - 10000C. ’ā╝ During this process the Carbon Dioxide is driven off. ’ā╝ Approximately 1kg of cement releases about 900gms of Carbon Dioxide into the atmosphere. ’ā╝ Therefore, green concrete came into existence to reduce the emission of carbon dioxide.

- 5. Materials for Green Concrete ’ā╝ Recycled Demolition Waste Aggregate ’ā╝ Recycled Concrete Aggregate ’ā╝ Blast furnace Slag (BFS) ’ā╝ Manufactured Sand ’ā╝ Glass Aggregate ’ā╝ Fly ash

- 6. Materials for GreenConcrete Coarse Aggregates are: Fresh local aggregate Recycled Demolition Waste Aggregate Recycled Concrete Material (RCM) Blast Furnace Slag (BFS)

- 7. Materials for GreenConcrete Fine Aggregate s are: Fly Ash Blast Furnace Slag (BFS) Manufactured Sand For Concrete Recycled Glass Aggregate

- 9. Cementitious materials ŌĆō ŌĆśFlyAshŌĆÖ Fly ash is a by-product produced during the operation of coal-fired power plants. The finely divided particles from the exhaust gases are collected in electrostatic precipitators. These particles are called Fly ash. Advantages Of Using Fly Ash in Concrete: 1.Utilization of fly ash as a part replacement of cement or as a mineral admixture in concrete saves on cement and hence the emission of CO2. 2.Use of good quality fly ash in concrete has shown remarkable improvement in durability of concrete, especially in aggressive environment.

- 10. a) Higher ultimate strength b) Increased durability c) Improved workability d) Reduced bleeding e) Increased resistance to alkali-silica reactivity. f) Reduced shrinkage. Someof the technicalbenefitsof theuseof flyashin GreenConcreteare:

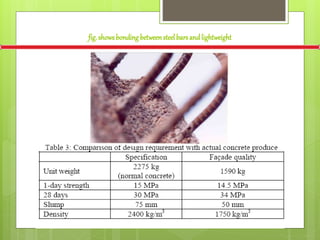

- 11. Synthetic lightweight aggregate produced from environmental waste is a viable new source of structural aggregate material. The uses of structural grade lightweight concrete reduce considerably the selfload of a structure and permit larger precast units to be handled. Water absorption of the green aggregate is large but the crushing strength of the resulting concrete can be high. The 28day cube compressive strength of the resulting lightweight aggregate concrete with density of 1590 kg/m3 and respective strength of 34 MPa. Most of normal weight aggregate of normal weight concrete is natural stone such as limestone and granite. Green lightweight aggregates

- 12. SUITABILITYOF GREENCONCRETEIN STRUCTURES Several factors which enhances the suitability of green concrete in structures include: 1. Reduce the dead weight of a structure of a facade from 5 tons to about 3.5 tons. 2. Reduce crane age load; allow handling, lifting flexibility with lighter weight. 3. Good thermal and fire resistance, sound insulation than the traditional granite rock. 4. Reduction of the concrete industry's CO2-emission by 30 %. 5. Increased concrete industry's use of waste products by 20%. 6. No environmental pollution and sustainable development. 7. Green concrete requires less maintenance and repairs.

- 13. APPLICATIONOF GREENCONCRETE Green concrete columns Green concrete bridge Green concrete dam Green concrete building

- 14. =: ADVANTAGES:- 1.Green concrete having better workability than conventional concrete. 2.Reduction in shrinkage & creep. 3.Green Concrete uses local and recycled materials in concrete. 4.The heat of hydration of green concrete is significantly lower than traditional concrete. 5.Good thermal resistant and fire resistant. 6.Compressive strength and Flexural behaviour is fairly equal to that of the conventional concrete.

- 15. LIMITATION ’ā╝ By using stainless steel, cost of reinforcement increases. ’ā╝ Structures constructed with green concrete have comparatively less life than structures with conventional concrete. ’ā╝ Split tension of green concrete is less than that of conventional concrete.

- 16. Green concrete is a revolutionary topic in the history of concrete industry. As green concrete is made with concrete wastes it does take more time to come in India because industries having problem to dispose wastes. Also having reduced environmental impact with reduction in CO2 emission. SCOPEIN INDIA

- 17. CONCLUSION Green concrete having reduced environmental impact with reduction of the concrete industries co2 aemissions by 30%. Green concrete is having good thermal and fire resistant. In this concrete recycling use of waste material such as ceramic wastes, aggregates, so increased concrete industryŌĆÖs use of waste products by 20% . Hence green concrete consumes less energy and becomes economical. So definitely use of concrete product like green concrete in future will not only reduce the emission of co2 in environment and environmental impact but also economical to produce.``

- 18. REFERRNCES ’é¦ Indian concrete journal volume 77-January- 2003-N0.-1Green concrete technology by R.M. Swamy on page no. 878 ’é¦ Green concrete using industrial wastes. Proceedings, National conferences on advances in building materials. Vellore Institutes of technology, Vellore. ’é¦ Devdas Manoharan.p.Senthamarai.R.M. Concrete using ceramic insulators scraps as coarse aggregates. Proceedings, 6th International conferences on conc. ’é¦ Galvind, MunchPetersen, Green concrete structural concrete. ’é¦ Websites:- ’é¦ http://www.greenconcrete.dk/ ’é¦ http://www.diamondbidewarehouse.com/green concrete.html.