green dot Master presentation

- 4. Marketing` Sales Branding Supply Chain Management Maintenance Quality control Health and safety Production Planning Store Human Resource Project Management Data Analysis Performance Management System Design and Development Cost / Profit Analysis Cost Management Training Area of Expertise

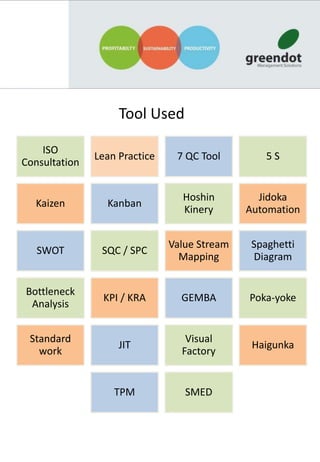

- 5. ISO Consultation Lean Practice 7 QC Tool 5 S Kaizen Kanban Hoshin Kinery Jidoka Automation SWOT SQC / SPC Value Stream Mapping Spaghetti Diagram Bottleneck Analysis KPI / KRA GEMBA Poka-yoke Standard work JIT Visual Factory Haigunka TPM SMED Tool Used

- 6. Improved Sales, Profit & Brand Image Reduce Machine down time Target Oriented work Planned work Systematic work with Minimal involvement of Top Management Reduced Down time Easy to train staff with systematic work Reduced cost Optimised Resources Easy Reporting System Analysis based Decision Better culture Quick ReponseTeam Improved Efficiency, Effectiveness, Productivity Scheduled work System for Easy to Train People Reduced inventory Proactive System instead of Reactive Result You can Expect

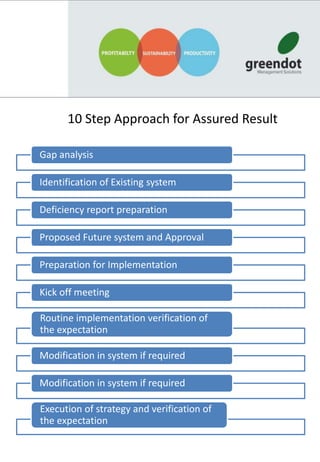

- 7. Gap analysis Identification of Existing system Deficiency report preparation Proposed Future system and Approval Preparation for Implementation Kick off meeting Routine implementation verification of the expectation Modification in system if required Modification in system if required Execution of strategy and verification of the expectation 10 Step Approach for Assured Result