Haccp for instend cooked rice

Download as PPTX, PDF2 likes5,612 views

This document summarizes the process for manufacturing instant rice. It describes 6 key steps: 1) receiving raw materials, 2) storage, 3) washing, 4) cooking, 5) drying, and 6) packaging. For each step, it identifies potential biological, physical and chemical hazards. It then lists control measures and critical control points to minimize these hazards. Specifically, it identifies cooking to a core temperature of 75┬░C as a critical control point to eliminate Bacillus cereus, and visual inspection for foreign matters during packaging with a maximum allowance of 1% as another critical control point.

1 of 19

Downloaded 39 times

Recommended

Physical and chemical hazards in food

Physical and chemical hazards in foodGihan Wijelath

╠²

A Food safety hazard is a biological, chemical or physical agent or condition of food with the potential to cause harm or an adverse health affect at the time of consumption.Haccp milk industry(pasteurization)

Haccp milk industry(pasteurization) geethuvavachi

╠²

The document outlines the Hazard Analysis and Critical Control Point (HACCP) system for milk processing. HACCP identifies seven principles for food safety that include hazard analysis, identifying critical control points, establishing critical limits, monitoring procedures, corrective actions, verification, and record keeping. The document then provides a hazard analysis for the milk processing steps from reception to packaging and storage. For each step, biological, chemical and physical hazards are identified and critical control points are established to eliminate or reduce the hazards.Packaging,Storing and Distribution

Packaging,Storing and Distribution zedtek

╠²

The document discusses packaging, storage, and distribution of food products. It describes the major functions of packaging as containing the product, protecting it, preserving it, informing consumers, and providing convenience. Different types of packaging materials are outlined, including cans, glass, paper, rigid and flexible plastics, aluminum foils, and laminates. Current developments in packaging focus on sustainability, biodegradability, modified atmosphere packaging, active packaging, sous vide techniques, and intelligent/convenient packaging innovations. Proper storage and distribution is also important to maintain food quality during manufacturing and transportation.Haccp of pineapple canned in syrup

Haccp of pineapple canned in syrupAtcharaporn Khoomtong

╠²

This document provides an overview of establishing a Hazard Analysis Critical Control Point (HACCP) system for canned pineapple sliced in syrup. It outlines assembling a HACCP team, describing the product and intended use, constructing a flow diagram, identifying hazards at each process step, determining critical control points, and establishing monitoring, corrective actions, and record keeping procedures. The key hazards identified include pathogenic bacteria from raw materials and equipment as well as chemical contamination from fertilizers, lubricants, and cleaning chemicals. Critical control points are established to control these hazards through measures such as supplier approval, equipment sanitation, and process monitoring.Haccp

HaccpBeverly Jane Espinosa

╠²

The document discusses Hazard Analysis and Critical Control Points (HACCP), a tool used to prevent food safety hazards. It outlines the seven principles of HACCP, including conducting a hazard analysis, determining critical control points, establishing critical limits, monitoring procedures, corrective actions, record keeping, and verification. The principles aim to anticipate where food safety problems could occur during food processing and production steps like purchase, delivery, storage, preparation, cooking, holding, and service, and establish controls to prevent issues.Haccp of milk pasteurization

Haccp of milk pasteurizationumairahmad76

╠²

This document presents an HACCP plan for milk pasteurization. It introduces HACCP and its seven principles for identifying and controlling food safety hazards. It then details the HACCP team members and provides a flow diagram of the milk pasteurization process. The document establishes critical control points along the process, including for raw material receiving, filtration, homogenization, pasteurization, cooling, packaging, and storage. For each critical control point, it identifies hazards, establishes critical limits for control, and outlines monitoring, corrective actions, and verification procedures. The goal is to prevent microbiological, physical and chemical hazards and ensure the safety of the pasteurized milk product.Haccp case study

Haccp case studymodern bakries group

╠²

This document provides guidelines for implementing Hazard Analysis Critical Control Point (HACCP) systems for food manufacturing premises in Dubai. It introduces HACCP and its seven principles, which were developed to ensure food safety. The guidelines aim to facilitate risk management programs and ensure foods in Dubai are safe for consumption. They cover all stages of the food chain from production to sale. The document provides definitions, outlines prerequisite programs, and gives steps for establishing a HACCP plan according to Codex Alimentarius standards. The guidelines are intended to help Dubai food establishments implement HACCP systems to protect public health.CIP and Manual cleaning

CIP and Manual cleaningSri Lanka German Training Institute

╠²

This document discusses various cleaning methods used in the food industry, including manual cleaning, mechanical cleaning using foam, immersion cleaning, cleaning-out-of-place (COP), and cleaning-in-place (CIP). It provides details on how each method works, advantages and disadvantages, and recommendations for effective cleaning.Good Manufacturing Practices in Food Processing

Good Manufacturing Practices in Food ProcessingPiumali Suraweera

╠²

This document discusses Good Manufacturing Practices (GMPs) in food processing. It covers several key areas:

1. The introduction outlines the development of GMPs due to commercial and legislative pressures to ensure quality and safety.

2. Buildings and facilities are important to prevent contamination and must be properly designed, constructed, and maintained. This includes considerations for grounds, plant construction, sanitary operations, and sanitary facilities.

3. Microbiological, chemical, and physical hazards are addressed through controls like hygienic practices, effective cleaning and sanitation procedures, environmental monitoring, supplier controls, and recall systems.HACCP Plan for Pineapple Jam Manufacturing Plant

HACCP Plan for Pineapple Jam Manufacturing Plant MuhammadSaqibJaved6

╠²

The Safety measures of Pineapple Jam can be improved, maintained and sustained by implementing HACCP Plan, as it covers all aspects during raw pineapple conversion to Pineapple Jam

Control of temperature and time duration in boiling unit and Quantity of Pectin and Temperature during Gelatinization are CCPs.

To obtained good hygienic Pineapple Jam these CCPs must be controlled and HACCP Plan must revised every year.HACCP Team Training

HACCP Team TrainingDenis M'Gee

╠²

This document provides an overview of Hazard Analysis and Critical Control Points (HACCP), a systematic preventative approach to food safety. It describes the 12 steps to developing and implementing an effective HACCP plan, including assembling a team, creating a process flow diagram, identifying hazards and critical control points, establishing monitoring procedures, and documenting the system. The goal of HACCP is to analyze food production processes and identify points where potential hazards can be controlled to improve food safety.Haccp final plan

Haccp final planPiumali Suraweera

╠²

Here are the key points about HACCP from the passage:

- HACCP stands for Hazard Analysis Critical Control Point system. It is a systematic approach to identify, evaluate, and control food safety hazards.

- The goal of HACCP is to prevent food safety hazards at the earliest possible point in the food chain rather than relying on end product inspection.

- Critical Control Points (CCPs) are steps in the food process where control can be applied to prevent, eliminate or reduce food safety hazards.

- HACCP was originally developed in the 1960s by NASA and the Pillsbury Company to ensure food safety for astronauts.

- HACCP requires companies to fundamentally change their culture andHaccp in milk industry ppt

Haccp in milk industry pptsafeena p a

╠²

This document discusses the implementation of Hazard Analysis and Critical Control Points (HACCP) in milk industries. It outlines the 7 principles of HACCP and identifies potential biological, chemical, and physical hazards at each processing stage - from raw milk collection through packaging and cold storage. Critical control points are established for pasteurization and product storage. Monitoring, corrective actions, verification, and record keeping procedures are described to control hazards and ensure food safety.Food preservation

Food preservationsanjayrumde

╠²

The document discusses food preservation through cold chain methods. It explains that food preservation aims to retain foods for longer periods without contamination or loss of quality by using techniques like freezing, refrigeration and cold storage. Cold chain ensures temperature-controlled storage and transport of foods from farms to processing to distribution and retail locations to maximize shelf life. Key methods discussed are freezing, refrigeration, pre-cooling and maintaining cold temperatures throughout the supply chain.HACCP Plan

HACCP PlanShyamala C

╠²

The document provides guidance on developing and implementing a Hazard Analysis Critical Control Point (HACCP) plan. It outlines the 12 steps to develop a HACCP plan, which includes assembling a HACCP team, describing products and processes, creating process flow diagrams, identifying hazards, determining critical control points, establishing critical limits and procedures for monitoring, corrective actions, verification, and record keeping. The document emphasizes that a HACCP plan is a systematic approach to identifying and controlling food safety hazards at critical points during food production.HACCP for Mango Pulp Processing plant

HACCP for Mango Pulp Processing plantAbdulrahmanmaan

╠²

HACCP for Mango Pulp Processing plant this will help you establish the HACCP plan for the Mango Pulp Industry.Calculating shelf life of foods

Calculating shelf life of foodsJaideep Banerjee

╠²

This document provides guidance for calculating shelf life of foods. It discusses factors that influence shelf life such as ingredients, processing, packaging and storage conditions. Regulations require date marking on packaged foods with shelf lives under two years. The person responsible for determining and labeling shelf life is usually the manufacturer, but can also include repackers, processors, retailers and supermarkets. Shelf life is related to both food quality and safety over the duration a food is stored according to any stated conditions. The guidance describes direct methods for experimentally determining shelf life through sensory and microbiological testing over time. It also discusses indirect methods and challenge testing.HACCP-cod fish

HACCP-cod fishTara Tousi

╠²

This document outlines the Hazard Analysis Critical Control Point (HACCP) plan for cod fish with herb and rice. It identifies potential hazards at each step in the process from receiving ingredients to holding the finished product. Critical control points are established at receiving, storing, thawing, cooking, and holding. Critical limits for temperature, time, and packaging integrity are specified. Monitoring procedures, corrective actions, and record keeping requirements are defined to control hazards at each critical control point.Retort pouch packing, aseptic packaging

Retort pouch packing, aseptic packaging Kamaraj College of Engineering & Technology, Virudhunagar

╠²

This document discusses retort pouch packaging and aseptic packaging. It describes retort pouches as a type of flexible packaging made from laminated plastic and metal foils. This allows for the sterile packaging of foods through aseptic processing, as an alternative to canning. The document outlines different retort pouch styles, materials, filling and sealing processes, defects to check for, integrity testing methods, and major players in the retort pouch industry. It also lists different types of microorganisms important to control in retorted foods through the thermal processing in retort pouches.HACCP implementation on cheddar cheese

HACCP implementation on cheddar cheeseUNIVERSITY OF AGRICULTURE FAISALABAD

╠²

This document outlines the HACCP implementation plan for a cheddar cheese production process. It begins with an overview of cheddar cheese and describes the process flow chart. It then identifies potential biological, chemical and physical hazards at each process step. For key steps identified as critical control points, it lists preventative measures, critical limits, monitoring procedures, frequency and corrective actions. The 11 process steps covered are raw milk receiving, pasteurization, ripening, setting, scalding, milling, salting, curing, cutting, packaging and storage/distribution. References are provided to support the HACCP analysis.Oprp vs ccp

Oprp vs ccpRavi Damani

╠²

This document discusses three types of prerequisite programs for food safety: PRPs, OPRPs, and CCPs. PRPs are general control measures that maintain a safe environment but do not control specific hazards. OPRPs control specific hazards but are not based on critical limits and their failure does not automatically mean a product is unsafe. CCPs are steps that control hazards through critical limits, which if not met, would make a product unsafe.Aseptic packaging

Aseptic packagingRischell Valmadrid

╠²

This document discusses aseptic processing and packaging. Aseptic processing involves sterilizing products, packaging materials, and facilities to prevent contamination. It results in shelf-stable products sealed in sterile packaging without refrigeration. The process includes UHT sterilization, filling in sterile environments, and hermetically sealed packages. Hyosung built Korea's first complete aseptic production facility with an annual capacity of 315 million bottles and state-of-the-art technology from preforms to filling. Aseptic packages provide benefits of portability, food safety from bacteria, and retaining more nutrients compared to canning.Tuna haccp

Tuna haccpRavindu Priyashan Perera

╠²

In this PPT, I have discussed how to apply HACCP for Canned Tuna processing line. And CP and CCP also considered. What are the hazards in the process line and how to prevent them are also mentioned. And how the HACCP team making and what are the qualities they should have also mentioned.Hazards analysis and critical control points

Hazards analysis and critical control pointsbenazeer fathima

╠²

This document provides an overview of Hazard Analysis and Critical Control Points (HACCP). It defines HACCP as a system that identifies, evaluates, and controls food safety hazards. The document outlines the seven principles of HACCP, which include conducting a hazard analysis, determining critical control points, establishing critical limits, monitoring procedures, corrective actions, record keeping, and verification procedures. It provides details on each principle and how they are applied to ensure food safety is controlled at critical points in the food production process.HACCP plan for pastry

HACCP plan for pastryEng. A.karam Al Malkawi

╠²

This document describes the application of Hazard Analysis and Critical Control Points (HACCP) quality control method to the production of pastry products without yeast. It identifies potential hazards in the production process and establishes critical control points to monitor and control hazards. Key points include identifying raw materials and the production process, establishing physicochemical and microbiological standards for the finished product, and procedures for verifying and reviewing the HACCP plan on a regular basis to ensure food safety.HACCP - Canned Tuna

HACCP - Canned Tuna Bobby Antan Caiquo

╠²

This document outlines the HACCP plan for canned tuna production. It identifies potential hazards at each step of production from raw material receipt through storage and distribution. The main hazards include microbial contamination or survival, presence of chemicals/toxins, and physical contamination. Preventive measures are proposed to control each hazard such as supplier specifications, temperature control, cleaning and sanitation procedures, monitoring of critical control points during heat processing and cooling. Critical limits for control points include temperature, chlorine levels, and can specifications. Record keeping of monitoring and corrective actions is required.FOOD QUALITY CONTROL

FOOD QUALITY CONTROLMariya Raju

╠²

This document discusses quality control in the food industry. It outlines several key aspects of a quality control program, including ingredient specifications, approved supplier lists, product formulations, manufacturing procedures, in-process records, packaging and labeling standards, and adherence to good manufacturing practices and sanitation. Maintaining quality is important to ensure safe, consistent food products and protect public health.The design of haccp plan for potato chips plant in bangladesh

The design of haccp plan for potato chips plant in bangladeshIstiak Mostofa

╠²

This document outlines the design of a Hazard Analysis and Critical Control Points (HACCP) plan for a potato chips plant in Bangladesh. It describes the potato chips production process and identifies potential food safety hazards like pathogens. The HACCP control chart shows the critical control points during frying and packaging where controls like temperature and time monitoring are implemented. The plan is intended to prevent, eliminate or reduce food safety hazards to acceptable levels and ensure the production of safe potato chips.Milling

MillingParimita Khatri

╠²

by

Er. Parimita

asstt. prof.

Sam Higginbottom Institute of Agriculture,Technology and Sciences.

naini,Allahabad

INDIARecipe Planning & Using Your Food Storage

Recipe Planning & Using Your Food Storagehappyinreno

╠²

The document provides tips for planning meals using food storage items, organizing food storage, and rotating items to maintain freshness. Key points include:

- Make a menu and calendar for meals using favorite recipes and food storage items. Organize recipes and store ingredients together.

- Properly storing, rotating, and incorporating food storage items into regular meals helps ensure freshness and prevents waste.

- Various methods are described for organizing and tracking food storage items to know what needs to be replaced and easily find ingredients for recipes.More Related Content

What's hot (20)

Good Manufacturing Practices in Food Processing

Good Manufacturing Practices in Food ProcessingPiumali Suraweera

╠²

This document discusses Good Manufacturing Practices (GMPs) in food processing. It covers several key areas:

1. The introduction outlines the development of GMPs due to commercial and legislative pressures to ensure quality and safety.

2. Buildings and facilities are important to prevent contamination and must be properly designed, constructed, and maintained. This includes considerations for grounds, plant construction, sanitary operations, and sanitary facilities.

3. Microbiological, chemical, and physical hazards are addressed through controls like hygienic practices, effective cleaning and sanitation procedures, environmental monitoring, supplier controls, and recall systems.HACCP Plan for Pineapple Jam Manufacturing Plant

HACCP Plan for Pineapple Jam Manufacturing Plant MuhammadSaqibJaved6

╠²

The Safety measures of Pineapple Jam can be improved, maintained and sustained by implementing HACCP Plan, as it covers all aspects during raw pineapple conversion to Pineapple Jam

Control of temperature and time duration in boiling unit and Quantity of Pectin and Temperature during Gelatinization are CCPs.

To obtained good hygienic Pineapple Jam these CCPs must be controlled and HACCP Plan must revised every year.HACCP Team Training

HACCP Team TrainingDenis M'Gee

╠²

This document provides an overview of Hazard Analysis and Critical Control Points (HACCP), a systematic preventative approach to food safety. It describes the 12 steps to developing and implementing an effective HACCP plan, including assembling a team, creating a process flow diagram, identifying hazards and critical control points, establishing monitoring procedures, and documenting the system. The goal of HACCP is to analyze food production processes and identify points where potential hazards can be controlled to improve food safety.Haccp final plan

Haccp final planPiumali Suraweera

╠²

Here are the key points about HACCP from the passage:

- HACCP stands for Hazard Analysis Critical Control Point system. It is a systematic approach to identify, evaluate, and control food safety hazards.

- The goal of HACCP is to prevent food safety hazards at the earliest possible point in the food chain rather than relying on end product inspection.

- Critical Control Points (CCPs) are steps in the food process where control can be applied to prevent, eliminate or reduce food safety hazards.

- HACCP was originally developed in the 1960s by NASA and the Pillsbury Company to ensure food safety for astronauts.

- HACCP requires companies to fundamentally change their culture andHaccp in milk industry ppt

Haccp in milk industry pptsafeena p a

╠²

This document discusses the implementation of Hazard Analysis and Critical Control Points (HACCP) in milk industries. It outlines the 7 principles of HACCP and identifies potential biological, chemical, and physical hazards at each processing stage - from raw milk collection through packaging and cold storage. Critical control points are established for pasteurization and product storage. Monitoring, corrective actions, verification, and record keeping procedures are described to control hazards and ensure food safety.Food preservation

Food preservationsanjayrumde

╠²

The document discusses food preservation through cold chain methods. It explains that food preservation aims to retain foods for longer periods without contamination or loss of quality by using techniques like freezing, refrigeration and cold storage. Cold chain ensures temperature-controlled storage and transport of foods from farms to processing to distribution and retail locations to maximize shelf life. Key methods discussed are freezing, refrigeration, pre-cooling and maintaining cold temperatures throughout the supply chain.HACCP Plan

HACCP PlanShyamala C

╠²

The document provides guidance on developing and implementing a Hazard Analysis Critical Control Point (HACCP) plan. It outlines the 12 steps to develop a HACCP plan, which includes assembling a HACCP team, describing products and processes, creating process flow diagrams, identifying hazards, determining critical control points, establishing critical limits and procedures for monitoring, corrective actions, verification, and record keeping. The document emphasizes that a HACCP plan is a systematic approach to identifying and controlling food safety hazards at critical points during food production.HACCP for Mango Pulp Processing plant

HACCP for Mango Pulp Processing plantAbdulrahmanmaan

╠²

HACCP for Mango Pulp Processing plant this will help you establish the HACCP plan for the Mango Pulp Industry.Calculating shelf life of foods

Calculating shelf life of foodsJaideep Banerjee

╠²

This document provides guidance for calculating shelf life of foods. It discusses factors that influence shelf life such as ingredients, processing, packaging and storage conditions. Regulations require date marking on packaged foods with shelf lives under two years. The person responsible for determining and labeling shelf life is usually the manufacturer, but can also include repackers, processors, retailers and supermarkets. Shelf life is related to both food quality and safety over the duration a food is stored according to any stated conditions. The guidance describes direct methods for experimentally determining shelf life through sensory and microbiological testing over time. It also discusses indirect methods and challenge testing.HACCP-cod fish

HACCP-cod fishTara Tousi

╠²

This document outlines the Hazard Analysis Critical Control Point (HACCP) plan for cod fish with herb and rice. It identifies potential hazards at each step in the process from receiving ingredients to holding the finished product. Critical control points are established at receiving, storing, thawing, cooking, and holding. Critical limits for temperature, time, and packaging integrity are specified. Monitoring procedures, corrective actions, and record keeping requirements are defined to control hazards at each critical control point.Retort pouch packing, aseptic packaging

Retort pouch packing, aseptic packaging Kamaraj College of Engineering & Technology, Virudhunagar

╠²

This document discusses retort pouch packaging and aseptic packaging. It describes retort pouches as a type of flexible packaging made from laminated plastic and metal foils. This allows for the sterile packaging of foods through aseptic processing, as an alternative to canning. The document outlines different retort pouch styles, materials, filling and sealing processes, defects to check for, integrity testing methods, and major players in the retort pouch industry. It also lists different types of microorganisms important to control in retorted foods through the thermal processing in retort pouches.HACCP implementation on cheddar cheese

HACCP implementation on cheddar cheeseUNIVERSITY OF AGRICULTURE FAISALABAD

╠²

This document outlines the HACCP implementation plan for a cheddar cheese production process. It begins with an overview of cheddar cheese and describes the process flow chart. It then identifies potential biological, chemical and physical hazards at each process step. For key steps identified as critical control points, it lists preventative measures, critical limits, monitoring procedures, frequency and corrective actions. The 11 process steps covered are raw milk receiving, pasteurization, ripening, setting, scalding, milling, salting, curing, cutting, packaging and storage/distribution. References are provided to support the HACCP analysis.Oprp vs ccp

Oprp vs ccpRavi Damani

╠²

This document discusses three types of prerequisite programs for food safety: PRPs, OPRPs, and CCPs. PRPs are general control measures that maintain a safe environment but do not control specific hazards. OPRPs control specific hazards but are not based on critical limits and their failure does not automatically mean a product is unsafe. CCPs are steps that control hazards through critical limits, which if not met, would make a product unsafe.Aseptic packaging

Aseptic packagingRischell Valmadrid

╠²

This document discusses aseptic processing and packaging. Aseptic processing involves sterilizing products, packaging materials, and facilities to prevent contamination. It results in shelf-stable products sealed in sterile packaging without refrigeration. The process includes UHT sterilization, filling in sterile environments, and hermetically sealed packages. Hyosung built Korea's first complete aseptic production facility with an annual capacity of 315 million bottles and state-of-the-art technology from preforms to filling. Aseptic packages provide benefits of portability, food safety from bacteria, and retaining more nutrients compared to canning.Tuna haccp

Tuna haccpRavindu Priyashan Perera

╠²

In this PPT, I have discussed how to apply HACCP for Canned Tuna processing line. And CP and CCP also considered. What are the hazards in the process line and how to prevent them are also mentioned. And how the HACCP team making and what are the qualities they should have also mentioned.Hazards analysis and critical control points

Hazards analysis and critical control pointsbenazeer fathima

╠²

This document provides an overview of Hazard Analysis and Critical Control Points (HACCP). It defines HACCP as a system that identifies, evaluates, and controls food safety hazards. The document outlines the seven principles of HACCP, which include conducting a hazard analysis, determining critical control points, establishing critical limits, monitoring procedures, corrective actions, record keeping, and verification procedures. It provides details on each principle and how they are applied to ensure food safety is controlled at critical points in the food production process.HACCP plan for pastry

HACCP plan for pastryEng. A.karam Al Malkawi

╠²

This document describes the application of Hazard Analysis and Critical Control Points (HACCP) quality control method to the production of pastry products without yeast. It identifies potential hazards in the production process and establishes critical control points to monitor and control hazards. Key points include identifying raw materials and the production process, establishing physicochemical and microbiological standards for the finished product, and procedures for verifying and reviewing the HACCP plan on a regular basis to ensure food safety.HACCP - Canned Tuna

HACCP - Canned Tuna Bobby Antan Caiquo

╠²

This document outlines the HACCP plan for canned tuna production. It identifies potential hazards at each step of production from raw material receipt through storage and distribution. The main hazards include microbial contamination or survival, presence of chemicals/toxins, and physical contamination. Preventive measures are proposed to control each hazard such as supplier specifications, temperature control, cleaning and sanitation procedures, monitoring of critical control points during heat processing and cooling. Critical limits for control points include temperature, chlorine levels, and can specifications. Record keeping of monitoring and corrective actions is required.FOOD QUALITY CONTROL

FOOD QUALITY CONTROLMariya Raju

╠²

This document discusses quality control in the food industry. It outlines several key aspects of a quality control program, including ingredient specifications, approved supplier lists, product formulations, manufacturing procedures, in-process records, packaging and labeling standards, and adherence to good manufacturing practices and sanitation. Maintaining quality is important to ensure safe, consistent food products and protect public health.The design of haccp plan for potato chips plant in bangladesh

The design of haccp plan for potato chips plant in bangladeshIstiak Mostofa

╠²

This document outlines the design of a Hazard Analysis and Critical Control Points (HACCP) plan for a potato chips plant in Bangladesh. It describes the potato chips production process and identifies potential food safety hazards like pathogens. The HACCP control chart shows the critical control points during frying and packaging where controls like temperature and time monitoring are implemented. The plan is intended to prevent, eliminate or reduce food safety hazards to acceptable levels and ensure the production of safe potato chips.Viewers also liked (6)

Milling

MillingParimita Khatri

╠²

by

Er. Parimita

asstt. prof.

Sam Higginbottom Institute of Agriculture,Technology and Sciences.

naini,Allahabad

INDIARecipe Planning & Using Your Food Storage

Recipe Planning & Using Your Food Storagehappyinreno

╠²

The document provides tips for planning meals using food storage items, organizing food storage, and rotating items to maintain freshness. Key points include:

- Make a menu and calendar for meals using favorite recipes and food storage items. Organize recipes and store ingredients together.

- Properly storing, rotating, and incorporating food storage items into regular meals helps ensure freshness and prevents waste.

- Various methods are described for organizing and tracking food storage items to know what needs to be replaced and easily find ingredients for recipes.Haccp on walnut oil

Haccp on walnut oilGoutham Matta

╠²

Tree nuts are hard-shelled fruits or seeds that are considered tree nuts. The United States is a dominant producer of tree nuts, with California producing 83% of US crops. Walnuts, almonds, and pistachios are primarily grown in California. Nuts provide nutrients but are also high in fat, so proper storage is important to prevent rancidity. A hazard analysis was performed to identify biological, chemical, and physical hazards during walnut oil production, such as mold growth and mycotoxin production, and control measures like good agricultural and manufacturing practices are established.Wheat

WheatN SENTHIL KUMAR

╠²

Wheat is classified by type, color, and hardness. Hard wheat is high in protein and used for breadmaking. Soft wheat has low protein and is used for pastries and cakes. Wheat is milled into flour through processes like cleaning, tempering, break milling, and reduction milling. This removes the bran and germ and produces white flour from the endosperm. Ideal wheat flour is high in starch, moderate in protein and moisture, and low in other components. The starch provides structure while proteins like gluten allow dough to rise and hold its shape when baked.Rice mill PPT by om

Rice mill PPT by omom Suryawanshi

╠²

This document summarizes the different processes involved in a rice mill, including cleaning, parboiling, drying, destoning, shelling, separation of paddy and brown rice, whitening to remove bran layers, grading to reduce broken rice, and final weighing, packaging and transportation. The key steps are cleaning of impurities from paddy, parboiling to improve milling quality, drying, destoning, shelling to remove husks, separation of components using trays and aspiration, whitening using an abrasive stone cone to remove bran layers, grading by size, and final weighing and packaging for transportation.Similar to Haccp for instend cooked rice (20)

Infrastructure Requirement & FSSAI Mandates

Infrastructure Requirement & FSSAI MandatesAnirudh Verma

╠²

The document discusses various infrastructure requirements for food businesses related to pest control, fire management, cooling equipment, dish washing, drainage systems, water supply, personnel facilities, health and hygiene practices. It outlines potential hazards of non-compliance in each area and corrective actions required such as proper pest proofing, maintenance of equipment, ensuring safe water supply, adequate employee facilities and health checks, pest control systems, and proper storage areas. Businesses must comply with these infrastructure and hygiene standards to obtain a food license and avoid penalties for violations.Coursemodulegensspdf 120730072618-phpapp02

Coursemodulegensspdf 120730072618-phpapp02Luchie Lingan

╠²

Food sanitation involves protecting food from contamination, harmful bacteria, and foreign bodies. It requires absolute cleanliness through personal hygiene, safe food handling, and clean facilities and equipment. Food safety is the top priority for food service employees to prevent foodborne illness. Three main causes of foodborne illness are cross-contamination, time-temperature abuse, and poor personal hygiene.Food hygiene

Food hygieneNuwan Darshana

╠²

This document discusses food hygiene and safety. It covers (1) the importance of protecting food from contamination and preventing bacterial growth, (2) the costs of poor food hygiene like food poisoning outbreaks and fines, (3) the benefits of good hygiene like satisfied customers and compliance with regulations, and (4) bacteria and the requirements for their growth. It also discusses high risk foods, food poisoning prevention, and the importance of personal hygiene for food handlers.FOOD HANDLING PICTURES.pptx

FOOD HANDLING PICTURES.pptxRioBurnama

╠²

This document provides guidelines and best practices for food handling and storage in a commercial kitchen. It discusses proper personal hygiene for food workers, types of food contamination to prevent, and methods for safely receiving, storing, preparing, displaying, and serving food. Specific topics covered include cleaning procedures, temperature control, labeling, separation of raw and cooked foods, and maintenance of equipment and storage areas. The overall goal is to ensure food safety and quality throughout the entire food production process.Pr3z3nt4t10n ni-m1ch34l

Pr3z3nt4t10n ni-m1ch34lSweetie Estupa

╠²

Sanitation and hygiene practices are essential in food processing plants to prevent contamination and ensure worker safety. Key practices include checking the quality of raw materials, monitoring production processes, proper packaging and labeling, and storing and transporting finished products in a way that prevents contamination. Worker hygiene such as handwashing and protective clothing is important, as is ensuring facilities are clean, well-ventilated, and pest-free. Maintaining thorough records also allows for quality control.Food santitation and safety

Food santitation and safetysri ramachandra university chennai

╠²

this slides will help and how to maintain food sanitation and safety in households ,hotels, restaurants and all food handling areas Food hygiene

Food hygieneDEBASISPARAMANIK

╠²

Unsafe food poses major risks, causing 2 million deaths per year from diseases like diarrhea, typhoid, and cancer. Foodborne illnesses strain healthcare systems and harm economies. Ensuring food safety requires proper handling practices like washing hands, preventing cross-contamination, cooking food thoroughly, and storing food at correct temperatures. Food safety is impacted by a variety of factors including globalization, urbanization, and climate change. Common foodborne diseases are caused by toxins, bacteria, viruses, and parasites transmitted through food. Legislation and standards aim to regulate food quality and safety.Food hygiene

Food hygienepranjal joshi

╠²

This document discusses food hygiene and safety. It covers the importance of protecting food from contamination, preventing bacterial growth, destroying harmful bacteria through cooking. Poor food hygiene can lead to food poisoning outbreaks and legal issues. Good hygiene practices like proper food handling and storage help comply with regulations and reduce waste. Bacteria growth is favored between 5-60 degrees C so food must be kept out of this temperature danger zone. Personal hygiene for food handlers is also essential to prevent contamination.2.TLE 9 GENERAL GUIDES IN THE CLEANLINESS AND SANITATION OF THE KITCHEN.pptx

2.TLE 9 GENERAL GUIDES IN THE CLEANLINESS AND SANITATION OF THE KITCHEN.pptxAirenLamsen

╠²

GENERAL GUIDESFood safety Managementsystem, indian perspective

Food safety Managementsystem, indian perspectiveVinay Kumar Srivastava

╠²

The document discusses food regulatory enforcement and compliance through inspection of food establishments. It begins by defining a food establishment and listing common types. It then outlines the objectives and regulatory basis for inspections. Key areas covered in inspections are described, including the layout and design of premises, equipment, facilities, operations, management, sanitation, pest control, and personnel hygiene. Special considerations for inspecting different types of food processing establishments are also provided. The roles of inspection, compliance, enforcement and recognition of audit agencies are discussed.Food Safety Refresher Program

Food Safety Refresher ProgramAnirudh Verma

╠²

The document discusses various factors related to food safety and hygiene. It covers topics like physical, chemical, and biological hazards, personal hygiene, temperature control, food storage, cleaning and sanitization, pest control, and allergies. It emphasizes the importance of proper handling, preparation, storage of food to prevent contamination and discusses best practices to avoid health hazards. It also provides guidelines on receiving, storing food, cleaning processes, temperature danger zones, and the role of hygiene in ensuring food safety.INFORM IN PREPARE AND COOK HOT DISHES.docx

INFORM IN PREPARE AND COOK HOT DISHES.docxladyaeris1994

╠²

Information about preparing and cooking hot Dishes Food Hygiene Essential

Food Hygiene Essentialssuser9e8f35

╠²

This document outlines an essential food safety training for food handlers at the Rosewood Abu Dhabi Hotel in January 2015. The learning objectives are to improve food safety knowledge, motivate safe practices, and ensure compliance. Key topics covered include foodborne illness prevention, personal hygiene, pest control, cross-contamination, cooking and chilling food safely, cleaning procedures, and the importance of separating raw and ready-to-eat foods. Food safety best practices such as proper handwashing, protective clothing, cooking to safe temperatures, and chillling food quickly are emphasized.Principles of food sanitation

Principles of food sanitationAkmal Hafiz

╠²

Food sanitation is more than just cleanliness. It included all practices involved in protecting food from risk of contamination, harmful bacteria, poisons and foreign bodies, preventing any bacteria from multiplying to an extent which would result in an illness of consumers; and destroying any harmful bacteria in the food by thorough cooking or processing.Purchasing storing (Ryuna Robles)

Purchasing storing (Ryuna Robles)TheaJasmineElyssaAle

╠²

The document discusses food safety guidelines for purchasing, storing, and handling food according to Hazard Analysis and Critical Control Point (HACCP) principles. It outlines seven HACCP principles including identifying potential food hazards, establishing preventative controls and monitoring procedures at critical points to ensure food safety. Specific guidelines are provided for foods like shellfish, fish, wild mushrooms and dairy products. Proper refrigeration and storage temperatures are emphasized to prevent bacterial growth and cross-contamination.Cereals and Cereal Products (Source of Contamination and preservations).pptx

Cereals and Cereal Products (Source of Contamination and preservations).pptxKeerthusara

╠²

Food Microbiology Flow of food

Flow of food babyCute19

╠²

The document discusses food safety procedures for purchasing, receiving, storing, preparing, and serving food. It covers proper temperatures for refrigeration, freezing, cooking, reheating and holding foods. Specific food safety guidelines are provided for meat, poultry, eggs, dairy and other products. Proper handwashing, cleaning, packaging and food rotation are emphasized throughout to prevent contamination and foodborne illness.Chapter 1 $2.pptx food and beverage preparation

Chapter 1 $2.pptx food and beverage preparationjalatatakala

╠²

Chapter 1 $2.pptx food and beverage preparationFood Processing Y3.pdf

Food Processing Y3.pdfLizaBano1

╠²

This document provides information about processing food by fermentation and pickling. It discusses preparing equipment, tools, and utensils for fermentation and pickling, including cleaning and sanitizing processes. Specific equipment, tools, and utensils used in fermentation and pickling are identified, such as refrigerators, ranges, weighing scales, fermentation vats, knives, and various cooking and measuring utensils. Steps for cleaning and sanitizing equipment are outlined.More from rooshi mk (8)

Vco

Vcorooshi mk

╠²

Virgin coconut oil is obtained from fresh coconut meat through mechanical or natural means without chemical processing. It provides health benefits such as improving immunity, reducing inflammation and risk of heart disease. Virgin coconut oil can be produced through various methods like hot processing, natural fermentation, or centrifugation. These methods involve extracting coconut milk from grated coconut meat and then separating the oil through processes like heating, fermentation, or high-speed centrifugation. The pure oil is then packaged for storage and use.Retort pouch processing

Retort pouch processingrooshi mk

╠²

This document discusses retort pouch processing for food products. Retort pouches allow for sterile packaging of foods through cooking under high pressure and heat. This increases shelf life while maintaining freshness. The document examines the materials used for retort pouches and the processing steps. It provides advantages like reduced heating time and easier distribution. A case study on ginger-garlic paste in retort pouches analyzes processing conditions and quality characteristics. The conclusion is that retort packaging enhances acceptance of ready meals and provides competition to canned foods.Food industry

Food industryrooshi mk

╠²

This document summarizes several major Indian financial institutions that provide funding to industrial sectors. It describes the objectives and functions of IFCI, ICICI, NIDC, NSIC, IDBI, IRBI, and SIDBI. IFCI, ICICI, and NIDC provide medium and long-term financing for industrial projects. NSIC, IDBI, and SIDBI specifically target small and medium enterprises, assisting with equipment, financing, and development. IRBI aims to revive struggling industries through loans, underwriting, and reconstruction support.Cashew

Cashewrooshi mk

╠²

This document provides information about cashew processing. It discusses the key steps in cashew nut processing which include cleaning, soaking, roasting, shelling, separation, grading, drying, peeling, and packaging. It also describes different equipment used such as pan roasters, drum roasters, shellers, graders, and dryers. Additionally, it outlines the main byproducts of cashew processing like cashew nut shell liquid and cashew nut shells which have various industrial and medicinal uses.Mini oil expellers

Mini oil expellersrooshi mk

╠²

The document discusses different methods for extracting oil from oilseeds:

1. Traditional animal-drawn ghanies use a mortar and pestle to crush seeds and extract oil through friction.

2. Mechanical expellers/screw presses use a rotating screw inside a barrel to press oil out of crushed seeds.

3. Solvent extraction involves grinding seeds and washing them with solvents like hexane to dissolve and extract the oil, which is then separated through heating and distillation.By products from pulse milling and its utilization

By products from pulse milling and its utilizationrooshi mk

╠²

Pulses are rich in proteins and are mainly consumed after milling, which removes the outer husk and splits the grain. Byproducts of milling include husk, peel, germ, and brokens. Dry milling produces brokens that can be used to make ready-to-fry snacks by cleaning, powdering, sieving, seasoning, kneading, cooking, and extruding. The husk can be used for solid state fermentation to produce tannin acyl hydrolase using red gram husk through inoculation, fermentation, extraction, immobilization, and purification by chromatography. Other byproducts include papad mixes, flour mixes, and animal/cattle feed produced through various preparationMicro encapsulation

Micro encapsulationrooshi mk

╠²

1. Microencapsulation involves coating tiny core materials with a polymeric shell to form capsules. It protects sensitive substances, masks tastes/odors, and controls drug release. Common techniques are spray drying, spray chilling, fluidized bed coating, and lyophilization.

2. A study encapsulated banana passion fruit pulp using maltodextrin and modified starch to preserve its high antioxidant activity for use as a natural food additive. Spray drying effectively microencapsulated the pulp while maintaining its phenolic content and antioxidant properties.

3. Another study encapsulated annatto seed extract for use as a natural food coloring. Spray drying with maltodextrin and gum arabic produced microMicroencaps

Microencapsrooshi mk

╠²

Microencapsulation is a process where tiny particles or droplets are surrounded by a polymeric material to form capsules. There are several techniques for microencapsulation including spray drying, spray chilling, fluidized bed coating, and lyophilization. The major steps common to many encapsulation techniques are preparation of a dispersion, homogenization, and drying or freeze-drying. Microencapsulation can protect sensitive substances, mask flavors, obtain controlled release, and avoid gastric irritation. Two case studies on microencapsulating banana passion fruit pulp and annatto seed extract are summarized to demonstrate applications of the technique.Haccp for instend cooked rice

- 1. WELCOME

- 3. ’éĪ Also known as minute rice. ’éĪ The rice that has been precooked and dehydrated so that it cooks more rapidly. ’éĪ For regular rice, it takes 20-60 minutes to cook. ’éĪ Instant rice needs anywhere between 5 and 10 minutes.

- 4. Receiving of raw material storage washing

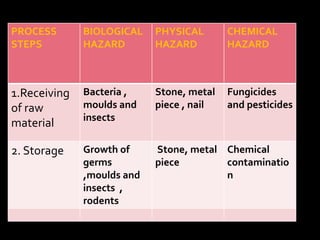

- 6. PROCESS STEPS BIOLOGICAL HAZARD PHYSICAL HAZARD CHEMICAL HAZARD 1.Receiving of raw material Bacteria , moulds and insects Stone, metal piece , nail Fungicides and pesticides 2. Storage Growth of germs ,moulds and insects , rodents Stone, metal piece Chemical contaminatio n

- 7. PROCESS STEPS BIOLOGICAL HAZARD PHYSICAL HAZARD CHEMICAL HAZARD 3. washing germs, contamination from food handlers, dirty equip., and wash water Contaminatio n from poorly maintained equip. Contaminatio n from wash water 4. Cooking Survival of germs Contaminatio n from poorly maintained equip. Contaminatio n from wash water

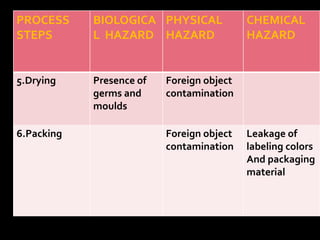

- 8. PROCESS STEPS BIOLOGICA L HAZARD PHYSICAL HAZARD CHEMICAL HAZARD 5.Drying Presence of germs and moulds Foreign object contamination 6.Packing Foreign object contamination Leakage of labeling colors And packaging material

- 9. Process steps Control measures Critical control point 1. Receiving of raw material Ensure packaging intact Purchase food within date code 2. Storage B - Store in dry well ventilated conditions P - Use covered storage containers

- 10. 4. Cooking: boiling B ŌĆō cook properly P - Use clean articles/equip. C - Use potable water CCP1 5.Drying B-Dry up to safe moisture content P-Use detectors CP

- 11. 6.Packaging P-Use the metal detectors C-Use appropriate packaging material and labeling ink CCP2 CP

- 12. ’é¦ CCP1-COOKING Core temp-75Ōü░C( Bacillus cereus) ’é¦CCP2-PACKAGING foreign matters- max 1% (m/m)

- 13. 1.Receiving of raw materials Check: Visual inspection of incoming goods Record: Presence/absence of contamination on invoice 2. Storage Check: Regular inspection of storage containers and surrounding structure Record: Record any resulting maintenance Check: Regular pest control inspections Record: Maintain pest control record book Check: Check date codes on a weekly basis Record: Record any wastage in wastage book

- 14. 3.Washing Check - Regular inspection of equipments. Record - Record any resulting maintenance Check - Supervisory check of personal hygiene Record - Record incidents of poor personal hygiene on personnel record 4.Cook Check-Visually check the boiling of rice for the period stated in the suppliers instructions

- 15. 5.Drying Check: using thermometer Record: temperature and time 6.Packing Check: visual control Record : packaging checks

- 16. 1.Receiving of raw materials - Reject contaminated or out of date code foods 2. Storage ’éĪ Repair/replace defective storage containers or structure ’éĪ Call specialist pest control contractor to get rid of pests identified ’éĪ Dispose out of date code stock

- 17. 3. washing Repair/replace defective articles/equip. Retrain food handlers 4. Cooking: boiling Continue boiling for stated period 5.Drying Dry up to safe moisture content 6.Packing Washout the material from packaging plant

- 18. ’é¦Staff training purposes ’é¦ Suppliers in the case of any disputes or problems ’é¦ Customer confidence ’é¦ Food safety inspection visits or investigations

- 19. THANKS ŌĆ”