HEAVY EQUIPMENT STANDARD SKILLS- AMERICAN

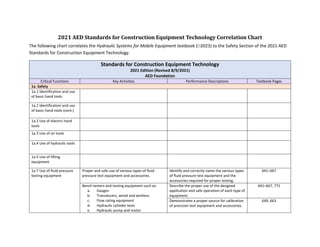

- 1. 2021 AED Standards for Construction Equipment Technology Correlation Chart The following chart correlates the Hydraulic Systems for Mobile Equipment textbook (©2023) to the Safety Section of the 2021 AED Standards for Construction Equipment Technology. Standards for Construction Equipment Technology 2021 Edition (Revised 8/9/2021) AED Foundation Critical Functions Key Activities Performance Descriptions Textbook Pages 1a. Safety 1a.1 Identification and use of basic hand tools 1a.1 Identification and use of basic hand tools (cont.) 1a.2 Use of electric hand tools 1a.3 Use of air tools 1a.4 Use of hydraulic tools 1a.5 Use of lifting equipment 1a.7 Use of fluid pressure testing equipment Proper and safe use of various types of fluid pressure test equipment and accessories. Identify and correctly name the various types of fluid pressure test equipment and the accessories required for proper testing. 641–667 Bench testers and testing equipment such as: a. Gauges b. Transducers, wired and wireless c. Flow rating equipment d. Hydraulic cylinder tests e. Hydraulic pump and motor Describe the proper use of the designed application and safe operation of each type of equipment. 641–667, 771 Demonstrates a proper source for calibration of precision test equipment and accessories. 649, 663

- 2. Correlation of Hydraulic Systems for Mobile Equipment to AED Standards for Construction Equipment Technology—page 2 Standards for Construction Equipment Technology 2021 Edition (Revised 8/9/2021) AED Foundation Critical Functions Key Activities Performance Descriptions Textbook Pages Exhibits knowledge of personal protection equipment and hazardous materials – reference section 1a.10. Identify, correctly name, and demonstrate the use of personal protective equipment required for the various types of fluid pressure testing equipment. 1–3, 14 Describe multiple dangers of working with fluids under pressure. 9–11 AED Standards Critical Functions Key Activities Performance Descriptions Textbook Pages 1a.8 Environment of service facility — 1a.9 Machine identification and operation Proper and safe operation of the machinery the technician will be involved with. Examples: a. Excavators b. Skid steers c. Backhoes d. Compaction equipment e. Paving equipment f. Crawlers and track type loaders g. Scrapers h. Cranes i. Scissor lifts j. Forklifts and material handlers k. Wheel loaders l. Haul trucks m. Motor graders n. Trenchers o. Horizontal directional drills Identify the various types of construction equipment and forklifts, using the standard industry names accepted by equipment manufacturers. 513 (Case Study), 498– 499 (Case Study), 544, 582–584, 587–593, 796–806 Demonstrates and can explain the proper, safe, and fundamental operation of the various types of machinery. 438–451, 455– 457,477–522, 527–557, 561–593, 597–615, 619–636 Translate from a user’s perspective the importance of and reasons for caution/warning lights, backup alarms, seat belts, safety instructions, decals, and other customer-related safety information. — ***Hybrid Drives*** Recognize hybrid systems and/or machines as they relate to safety concerns. 356–359 Exhibits knowledge of personal protection equipment and hazardous materials – reference section 1a.10.

- 3. Correlation of Hydraulic Systems for Mobile Equipment to AED Standards for Construction Equipment Technology—page 3 AED Standards Critical Functions Key Activities Performance Descriptions Textbook Pages 1a.10 Mandated regulations Various federal and state OSHA and MSHA regulations. Identify and correctly name the various types of equipment required for these regulations. 1–9, 13–14 a. Personal protection equipment (PPE): • Safety glasses and shoes • Fire protection • Ear protection • Respirators • Head protection • Loose clothing hazard • Proper gloves/hand protection • Protective clothing Demonstrate and explain the principles and procedures for each of the regulations. 1–17 Demonstrates the operation, inspection, proper care, and maintenance of the various equipment required for conforming with federal and state OSHA and MSHA regulations. 1–17 b. Hazardous material: • Right-to-know c. Proper handling of hazardous material. d. Lock-out, tag-out as it pertains to construction machinery. e. Proper use of wheel chocks. f. Blood-borne pathogens. g. Confined space regulations. h. Forklift operation and certification. i. Fire protection and suppression: • Methods of fire protection • Proper handling of various types of fires; electrical, grease, etc. • Use of fire extinguishers Identify the different types of fire extinguishers and know the applications and correct use of each type. 3–6 j. Safety Data Sheets (SDS). Demonstrate how to find, explain, and use an SDS for a product. 6–7 k. Machine guarding. l. Proper inspection of all electrical tools. Example: Drills and grinders. m. Handling of flammable liquids and materials. n. Handling of machinery with fluid leaks. o. Back-up alarm requirements for construction machinery.

- 4. Correlation of Hydraulic Systems for Mobile Equipment to AED Standards for Construction Equipment Technology—page 4 AED Standards Critical Functions Key Activities Performance Descriptions Textbook Pages p. Rollover protective equipment for construction machinery (ROPS). q. Electrical ground fault protection. 1a.10 Mandated regulations (cont.) r. Underground utility hazard – standard markings for each type. Recall and identify underground utility hazard markings that would commonly be encountered on a job site. — s. Falling objects protection for construction machinery (FOPS). t. Fall protection for workers. u. Sub-surface, trench, and excavation safety. v. Workman’s compensation and accident prevention: 1. Cost of accidents 2. Lost time injury 3. Proper accident and injury reporting Explain why working safety is important and explain the procedures for reporting unsafe working conditions and practices. 1–2, 10, 11 (Case Study), 13–14 1a.11 Shop and in- field practices General safe work habits in the shop; general safe work habits when doing in-field repairs or at customer’s facility. Identify safe work practices in each situation. 1–4, 13–14 Demonstrate safe work practices in the shop or in the field. 1–4, 13–14, 164–166, 346–348 Proper lifting and pulling techniques. Identify proper lifting and pulling techniques to avoid personal injury. — Demonstrate proper lifting and pulling techniques. — Proper shop/facility cleanliness and housekeeping practices. Demonstrate proper shop/facility cleanliness/appearance to dealer standards. 6, 309–310, 325–326, 331–333 1a.12 Hazard identification and prevention Performing safety risk assessments. Identify potential hazards and develop a plan to deal with them. 12–14 Proper mounting and dismounting of machinery. Demonstrate safe mounting and dismounting practices on construction machinery. 12–14 Load securement for transportation of components. Explain proper types of chains and binders used in securing loads. — General knowledge of safety practices. Demonstrate proper lock-out, tag-out procedures. 12–14

- 5. Correlation of Hydraulic Systems for Mobile Equipment to AED Standards for Construction Equipment Technology—page 5 AED Standards Critical Functions Key Activities Performance Descriptions Textbook Pages Hazard Communication (HazCom) Standard. Demonstrate understanding of the HazCom standard and how to use Safety Data Sheets and Chemical Labels. 6–7, 15–17 Implement Toolbox Talk, or Safety Share Topic in daily startup. Write about or discuss from personal or team experience (shop, workplaces, etc.), common safety hazards, and what you would have done to eliminate them. — Proper use of jack stands, blocking, and cribbing while working under a machine. Demonstrate proper work procedures in handling wheel assemblies safely. Refer to industry standard procedures. — Proper wheel assembly handling procedures. 1a.12 Hazard identification and prevention (cont.) Proper tethering techniques. Identify when tethering is necessary and proper use of the fall protection equipment. 14 Note: If service vehicles are used in training, basic safety instruction should extend to include the vehicle as well as devices such as cranes, compressors, generators, pumps, winches, etc. Local equipment dealers may be helpful in providing training for field service trucks and other vehicles.