High voltage circuit breakers

- 1. 1 HIGH VOLTAGE CIRCUIT BREAKERS Presented by, KABILESH. K (15BEE023)

- 2. CONTENTS ’üĄ Introduction ’üĄ Circuit Breaker ’üĄ Components of circuit breaker ’üĄ Working Principle ’üĄ Arc Formation ’üĄ Methods of Arc quenching ’üĄ Types of Circuit Breakers ’üĄ Conclusion 2

- 3. INTRODUCTION ’üĄ Nowadays, the modern power system deals with huge power network and huge numbers of associated electrical equipment. ’üĄ During short circuit fault or any other types of electrical fault these equipment suffer a high stress of fault current which may damage the equipment and networks. ’üĄ For saving these equipments and the power networks, the fault current should be cleared from the system as quickly as possible. ’üĄ These complications have paved the way for the evolution of circuit breakers. 3

- 4. CIRCUIT BREAKER ’üĄ A circuit breaker is an electromechanical switch that breaks the circuit either manually or automatically under all conditions at no load, full load or short circuit. ’üĄ Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation. ’üĄ Its basic function is to detect a fault condition, by interrupting continuity and immediately discontinue the electrical flow. 4

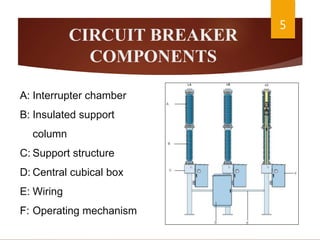

- 5. CIRCUIT BREAKER COMPONENTS 5 A: Interrupter chamber B: Insulated support column C: Support structure D: Central cubical box E: Wiring F: Operating mechanism

- 6. WORKING PRINCIPLE ’üĄ The circuit breaker mainly consists of fixed contacts and moving contacts. ’üĄ In normal ON condition of circuit breaker, these two contacts are physically connected to each other due to applied mechanical pressure on the moving contacts. ’üĄ The potential energy can be stored in the circuit breaker by different ways like by deforming metal spring, by compressed air, or by hydraulic pressure. ’üĄ During fault condition, potential energy must be released. Release of potential energy makes sliding of the moving contact at extremely fast manner and breaks the circuit. 6

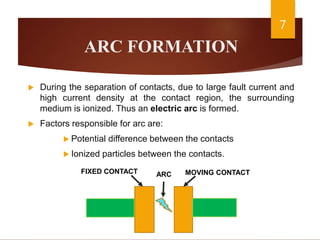

- 7. ARC FORMATION ’üĄ During the separation of contacts, due to large fault current and high current density at the contact region, the surrounding medium is ionized. Thus an electric arc is formed. ’üĄ Factors responsible for arc are: ’üĄ Potential difference between the contacts ’üĄ Ionized particles between the contacts. MOVING CONTACTFIXED CONTACT ARC 7

- 8. METHODS OF ARC QUENCHING ’üĄ High Resistance Method: Arc resistance is made to increase with time so that current is reduced to a value insufficient to maintain the arc. ’üĄ Low Resistance Method: Dielectric Medium between the contacts is built up more rapidly so that the arc fails to restrike and the current will be interrupted. ’üĄ Arc Resistance depends on factors like: Degree of Ionization Length of the arc Cross section of arc 8

- 9. TYPES ’üĄ Oil Circuit Breakers ’üĄ Vacuum Circuit Breakers ’üĄ Air Blast Circuit Breakers ’üĄ SF6 Circuit Breakers 9

- 10. OIL CIRCUIT BREAKERS ’üĄ These are the oldest type circuit breakers. ’üĄ It can be operated 11kV - 765kV. ’üĄ Oil is used as arc quenching media as well as insulating media between current carrying contacts and earthed parts of the breaker. ’üĄ These are of two types: ’üĄ BOCB (Bulk oil Circuit Breaker) ’üĄ MOCB (Minimum oil Circuit Breaker) ’üĄ The oil used here is same as transformer insulating oil. 10

- 11. VACUUM CIRCUIT BREAKERS ’üĄ It is operated at medium voltage range (3.3 - 33kV). ’üĄ The arc quenching takes place in vacuum. ’üĄ A vacuum interrupter is a switch which uses electrical contacts in a vacuum for the process of quenching the arc. ’üĄ The vacuum pressure inside a vacuum interrupter is normally maintained at 10-6 bar. ’üĄ The technology is suitable for mainly medium voltage application. For higher voltage vacuum technology has been developed but not commercially viable. 11

- 12. AIR BLAST CIRCUIT BREAKERS ’üĄ It operates using high velocity blast of air which quenches the arc. ’üĄ The contacts are opened in a flow of air blast and quenches the arc. ’üĄ This rapidly increases the dielectric strength of the medium between contacts and prevents from arc. ’üĄ Then the arc is extinguished and flow of current is interrupted. 12

- 13. SF6 CIRCUIT BREAKERS ’üĄ It uses Sulphur Hexafluoride (SF6) gas as an arc quenching medium. ’üĄ In closed position, SF6 gas pressure - 2.8 kg/cm2 ’üĄ In opened position SF6 gas pressure- 14 kg/cm2 ’üĄ SF6 is released from a valve and rapidly absorbs the free electrons in the arc path to form immobile negative ions to build up high dielectric strength and extinguishes it. ’üĄ After operation the valve is closed by the action of a set of deformed springs. 13

- 14. CONCLUSION ’üĄ Circuit breaker is the most essential part of the electrical networks as it protects every device from damage. ’üĄ By using appropriate circuit breaker for appropriate operating voltages we can provide protection for bus bar and electrical equipments like Power transformers, generators, C.T, P.T, etc. from different faults that occur in power system. 14

- 15. 15