Hirschmann Fixturing System 5000

- 2. Tooling Set Includes : ’é© H8.811 - Clamping Block: List Price: $2,260 ’é© H5.50.66/2 ŌĆōSurface Finder with Ball 2mm List Price: $1,160 ’é© H5.50.8 ŌĆō Aligning Rule List Price: $1,060 ’é© H5.50.9 ŌĆō Aligning Gauge List Price: $1,080 ’é© H5.51.11 ŌĆō Minifix Pallet (set of 30) List Price: $ 300 ’é© H5.51.15 ŌĆō Minifx F Holder List Price: $ 460 ’é© H5.51.16 ŌĆō Minifix V Holder List Price: $ 460 ’é© H5.50 ŌĆō x 2 E Pallet (50 sq.) List Price: $ 280 ’é© H8.11.10 ŌĆō Pneumatic Tool Clamper List Price: $4,260 ’é© H5.51.1 x 2ŌĆō Minifix Stainless Pallet Holder List Price: $ 820 ’é© H5.62.25 x 2 ŌĆō Magazine Fork List Price: $ 410 --------------------------------------------------------------------------------------------- Total List Price :$14,060 40% Package Deal Discount - $5,624 --------------------------------------------------------------------------------------------- Total Selling Price: $8,436

- 3. H 5.50.8 -Test Bar For aligning and checking the axis and radial position of the mounted tool clampers, and for concentricity and system checks

- 4. H 5.50.9 Aligning Gauge For aligning and checking the tool and pallet clampers in the X/Y ŌĆō direction, and for checking the quill/pallet clamper in the center direction.

- 5. H5.51.11 Minifix Pallet (Set of 30-Rust Proof) Aluminum, x 20 mm (0.787ŌĆØ), with reference point, for electrodes of copper and graphite. For attachment on the electrode blank by single-package system (glue), e.g. H 50 K. A fastening thread M 6 with a length of approx. 12 mm (0.472ŌĆØ) is drilled into the electrode through the central hole. The pallet glued to the electrode is fastened to the holder precisely and frictionally by means of the central screw, under consideration of the reference points. Transmission of the current by the central screw

- 6. H 5.51.1 Minifix Stainless Pallet Holder - Short r precise and angular fixing of the MINIFIX and MINIFIXplus electrodes, pallets and holder dexing in precision-ground centering Vee blocks. With internal flushing and external flushin The central draw spindle has a continuous flushing hole. Repetitive accuracy of the pallet same holder) l 0.005 mm (0.0002ŌĆØ) Changing accuracy (holder-holder) ┬▒ 0.005 mm (0.0002ŌĆØ Same length for all holders ┬▒ 0.005 mm (0.0002ŌĆØ)

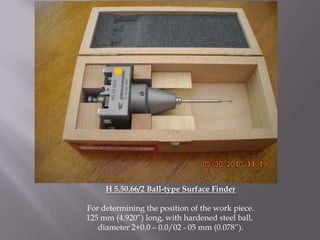

- 7. H 5.50.66/2 Ball-type Surface Finder For determining the position of the work piece. 125 mm (4.920ŌĆØ) long, with hardened steel ball, diameter 2+0.0 ŌĆō 0.0/02 - 05 mm (0.078ŌĆØ).

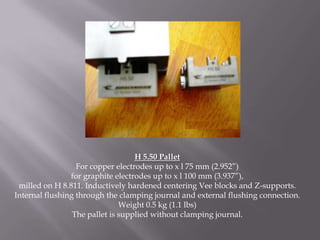

- 8. H 5.50 Pallet For copper electrodes up to x l 75 mm (2.952ŌĆØ) for graphite electrodes up to x l 100 mm (3.937ŌĆØ), milled on H 8.811. Inductively hardened centering Vee blocks and Z-supports. Internal flushing through the clamping journal and external flushing connection. Weight 0.5 kg (1.1 lbs) The pallet is supplied without clamping journal.

- 9. H 5.51.15 F-Holder tainless steel, nitrided with reference point. For fixturing of small flat electrodes as e.g. sma sheet metal or rod electrodes up to 5 x 12 mm (0.196ŌĆØ x 0.472ŌĆØ). H 5.51.16 V-Holder Stainless steel, nitrided with reference point. For fixturing of small electrodes up to x l10 mm (0.393ŌĆØ).

- 10. H 8.11.10 Tool Clamper (without MINIFIXplus) Compressed air and dielectric are supplied from above.The rear of the clamper is ground as an alignment surface parallel to the centering Vee block Positioning and repetitive accuracy 0.002 mm (0.00008ŌĆØ) / Clamping force (clamper without MINIFIXplus) 2500 N Clamping force (clamper with MINIFIXplus) 1500 N / Permissible electrode weight 100 kg (220.5 lbs)

- 11. Magazine Fork

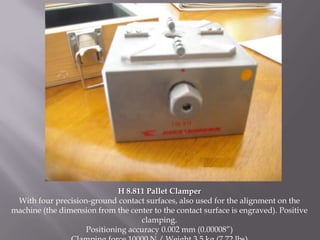

- 12. H 8.811 Pallet Clamper With four precision-ground contact surfaces, also used for the alignment on the machine (the dimension from the center to the contact surface is engraved). Positive clamping. Positioning accuracy 0.002 mm (0.00008ŌĆØ)