Hose_QMS_Presentation

- 1. Well Testing Global Hose Management

- 2. Introduction • Establish a global standard for Identification, use and management of hoses used by Expro in all maintenance and operational activities within the Well Test product line. This procedure shall also identify the dangers associated with improper hose end connections, usage, storage and transportation. ®Copyright Expro 201 WELL FLOW MANAGEMENT

- 3. Why Hose Management? • Better way of doing things • To Standardize Procedure • Continuous Safety Improvement • High potential near miss 3” Hose Connection Part Off. Alert ref Asia/Alert/2007/002. April 2007 Hose rupture from flare boom, bulletin no: HSEB-09-21. Oct 2009 Hose burst while in used offshore, alert no: EPTI-11-006. July 2011 ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 4. Scope The extent of this procedure is from procurement of hoses to discard. • Responsibilities • Identification • Hose Tracking • Hose Inspection • Rig Up • Rig Down • Maintenance • Storage • Transportation • Discard ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 5. Responsibilities All Expro employees shall follow the procedure outlined in this document. • Line Managers and Supervisors Are to ensure that all procedures are enforced and lead by example • Technicians Operators Workshop Personnel Are to follow the procedures outlined in this document. ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 6. Procurement/Purchase • Vendors Vendors shall be approved by manufacturer to sell hoses. • Purchaser Ensure all specifications are given to the Vendor. • Receiving Cross check hose with specifications. ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 7. Hose Identification All hoses shall have the following identifying bands on them. • Manufactures Band Band shall have Unique Asset Number, Manufacture Date (not to exceed (3) years) and Max working pressure • Expro Band Band shall have last dated tested on it and should be within a year of current date. ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 8. • Types of hoses Used • Specification Temperature and pressure ratings Material design End connections Standard ®Copyright Expro 2010 WELL FLOW MANAGEMENT

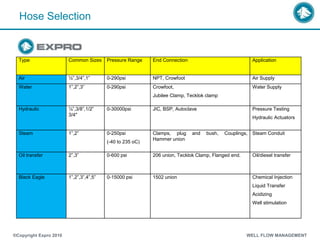

- 9. Hose Selection ®Copyright Expro 2010 WELL FLOW MANAGEMENT Type Common Sizes Pressure Range End Connection Application Air ½”,3/4”,1” 0-290psi NPT, Crowfoot Air Supply Water 1”,2”,3” 0-290psi Crowfoot, Jubilee Clamp, Tecklok clamp Water Supply Hydraulic ¼”,3/8”,1/2” 3/4" 0-30000psi JIC, BSP, Autoclave Pressure Testing Hydraulic Actuators Steam 1”,2” 0-250psi (-40 to 235 oC) Clamps, plug and bush, Couplings, Hammer union Steam Conduit Oil transfer 2”,3” 0-600 psi 206 union, Tecklok Clamp, Flanged end. Oil/diesel transfer Black Eagle 1”,2”,3”,4”,5” 0-15000 psi 1502 union Chemical Injection Liquid Transfer Acidizing Well stimulation

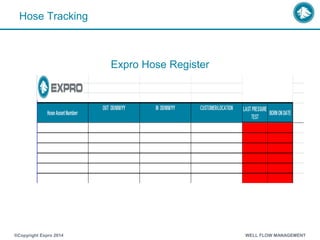

- 10. Hose Tracking ®Copyright Expro 2014 WELL FLOW MANAGEMENT Expro Hose Register

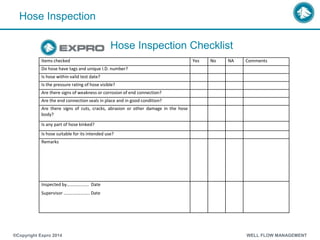

- 11. Hose Inspection ®Copyright Expro 2014 WELL FLOW MANAGEMENT Hose Inspection Checklist Items checked Yes No NA Comments Do hose have tags and unique I.D. number? Is hose within valid test date? Is the pressure rating of hose visible? Are there signs of weakness or corrosion of end connection? Are the end connection seals in place and in good condition? Are there signs of cuts, cracks, abrasion or other damage in the hose body? Is any part of hose kinked? Is hose suitable for its intended use? Remarks Inspected by…………....... Date Supervisor ………………….. Date

- 12. Rig Up/Rig Down • Pre-Rig Up Checks • Rig up Guide • Rig Down Guide ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 13. Maintenance • Post Job • Annual Pressure Test • Pressure Testing Parameters ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 14. Storage • Storage Specifications ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 15. Transportation • Proper Arrangement No heavy objects placed on top Hung on racks if provided Loose items shall be restricted from movement ®Copyright Expro 2014 WELL FLOW MANAGEMENT

- 16. Discard of Hoses • Discard Criteria • Discard Procedures ®Copyright Expro 2014 WELL FLOW MANAGEMENT