Howto2 two piece mold

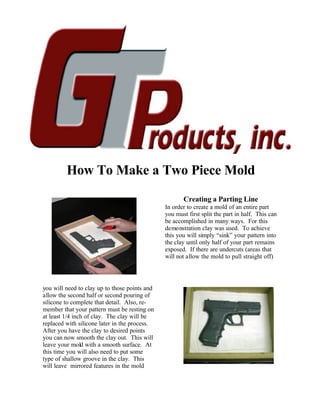

- 1. How To Make a Two Piece Mold Creating a Parting Line In order to create a mold of an entire part you must first split the part in half. This can be accomplished in many ways. For this demonstration clay was used. To achieve this you will simply ˇ°sinkˇ± your pattern into the clay until only half of your part remains exposed. If there are undercuts (areas that will not allow the mold to pull straight off) you will need to clay up to those points and allow the second half or second pouring of silicone to complete that detail. Also, re- member that your pattern must be resting on at least 1/4 inch of clay. The clay will be replaced with silicone later in the process. After you have the clay to desired points you can now smooth the clay out. This will leave your mold with a smooth surface. At this time you will also need to put some type of shallow groove in the clay. This will leave mirrored features in the mold

- 2. Apply a Release Agent It is always a good practice to apply some type of release agent to your parts before pouring any type of liquid material on them. This will prevent the mold making material from sticking to your pattern. It will also make it easier to remove the mold from your pattern after your mold has cured. Pouring Your Mold When making a mold with silicone it is al- ways important to take your time. Whe n- ever possible you should pour the silicone in an area that is not in contact with your pattern and allow the silicone to roll over your pattern slowly. This will help prevent air bubbles from being trapped against the pattern. Brushing Off Bubbles No matter how careful you are when mixing and pouring silicone you will always have some air in the material This air will rise to the surface. . If these bubbles are allowed to remain they will create holes against your lid and could cause deformation in your parts when you begin pour- ing parts. These bubbles can be popped by lightly scraping across the surface or by blow- ing air across the surface. Applying The Lid After most of the bubbles have risen to the surface and popped it is now time to put the first lid on. Begin by applying the lid in one corner and allow it to lie down toward the opposite corner. This will force excess sili- cone in one direction and make it easier to close. You will tighten the lid down using the same method.

- 3. Removing The Clay After the silicone is hardened you can now remove the clay. Most of the clay should come out in one mass. You will then need to clean the remaining clay that sticks in corners and in finer details. All of the clay must be removed for the second half of the mold to be consistent with your pattern. Applying Inlets and Vents Inlets and vents can be applied to your pat- tern in many ways. The inlet will give you a place to pour your parts through. The vents will provide a place for air bubbles that would be trapped in details to escape while pouring your parts. Applying Mold Release After all of the vents are in place you will need to spray the mold with a release agent. If release is not used at this point the two halves of the mold will stick together and you run the risk of damaging your pattern. Mixing and Pouring You will follow the same steps in mixing and pouring as you did for the first half. During this pour, however, you will need to take care as to not bump the inlets and vents which could cause them to break loose.

- 4. Allow The Silicone to Flow As in the first pour allow the silicone to flow over the pattern and into the details of the pattern. This will also enable the sili- cone to slowly fill in around the inlets and vents and prevent air from being trapped. It will also place less pressure on the vents which could displace them. Allow Bubbles to Rise and Silicone to Level Regardless of how careful you are in mixing and pouring silicone there will be air trapped. You will need to allow the air time to rise out of the mold. During this time the silicone will level itself. This will make it easier to attach the lid to the box. Brushing Off Bubbles Just as you did in the first half, you will need to lightly brush off the bubbles. The only difference this time will be that you need to be careful not to disturb the inlet as it will break off. Applying the lid Holes will need to be drilled into the lid to make a place for the inlets to pass through. These holes will need to be large enough for silicone to fill in around the inlets. Apply the lid in the same way you did the first but again take care as to not disturb the inlets.

- 5. Preparing to Pour Parts After the mold has hardened and you have removed the pattern you are now ready to begin pouring parts. You will first spray a release agent on the mold. This will prevent the material you are pouring from adhering to the mold. A consistent coat of release before every pour will also greatly improve you mold life. Mixing Material Pour each of the components together and begin mixing. Take care to make sure that the material is thoroughly mixed. Scrape the sides of the container and the bottom oc- casionally. Pouring the Material You will need to have some type of funnel to pour into. It is always a good idea to pour down the inside wall and allow the material to roll down the side. This will keep the material from splashing and also help reduce the possibility of putting air into the mold. Filling The Mold The mold should be sitting at about a 45o angle. This will give you one single high point. Having this one high point will allow the air that is in the mold to all be pushed toward this one single spot, thus evacuating as much air as possible, leaving you will a part that should have few voids in it.

- 6. Pulling Your Part After allowing the required amount of time for your material to harden you can pull your part out of the mold. The silicone will be flexible and allow you to bend it off of the part. You will need to be more careful in tight areas as to not place undo stress on the mold and damage details on your part. The Final Product If all of the steps have been completed suc- cessfully then you should have a final part that is a replica of your original. You can now take that part and perform final clean up and sanding processes to finish out your part and make it look great. These are the basic steps in making and using a two piece mold. Finer details may have been omitted as every project has individual characteristics that may require more steps. If you have any questions about the process please do not hesitate to give us a call.