HVAC.ppt heating ventillation and air conditioning

- 1. AUTOMOTIVE AIRCONDITIONING SYSTEM, SERVICING, REPAIRING AND MAINTENANCE

- 2. HISTORY The main job of refrigeration and air- conditioning system is to cool a certain place, particles or a substance down to, and maintain them at a temperature lower than the normal ambient temperature.

- 3. Air-conditioning can be define as a process that removes heat. The oldest and most well known among refrigerants are ice, water and air. In the beginning, the sole purpose was to conserve food. The Chinese were the first to find out that ice increased the life and improved the taste of drinks and for centuries people have conserve food by freezing it, and it was followed to discover by the egyptians.

- 4. The idea of air-conditioning started before a machine was created to produce the cooling effect desired. Evaporative cooling has been around in one form or another for some time. The Persians used a wind catcher system to pull air down through a tower and over water to provide cooling in the summer months and there are still many of these visible today.

- 6. Today, air-conditioning is regarded as normal necessities. There are countless applications for air- conditioning now. Examples are foodstuff conservation, process refrigeration, ice production, household air-conditioning, vehicle air-conditioning and others. In fact, it is difficult to imagine life without air conditioning, refrigeration and freezing, their impact on our existence is much greater than most people imagine.

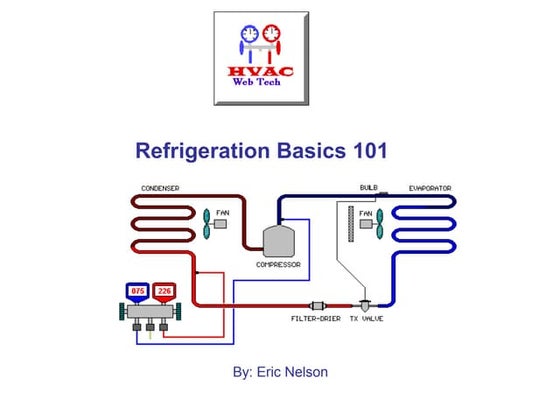

- 7. THE REFRIGERATION CYCLE ŌĆó The LP/LT gas refrigerant enters the compressor through the suction service valve. The gas is drawn into the cylinder of the compressor and compressed by the piston which becomes HP/HT gas refrigerant. It is then discharged through the discharge service valve into the condenser.

- 8. ŌĆó In the condenser, the heat drawn from the evaporator and from the heat of compression are given up to air flowing from the condenser thus making the refrigerant change its state from gas to liquid, but still in HP/HT but in liquid form. It will then pass to the receiver drier.

- 9. ŌĆó The receiver drier stores the liquid refrigerant and filter any dirt or tiny particles inside the system. It is equipped with a fusible plug set to discharge at around 350 F in the event of abnormal increase of temperature. A sight glass is also installed to provide a quick and easy way of checking the refrigerant charge of the system. If you see any sign of bubbles or foam like substances, this indicate a shortage of refrigerant. The refrigerant then flows to the thermostatic expansion valve.

- 10. ŌĆó The expansion valve has a sensing bulb clamped to the suction line or after the evaporator exit. The main function of the thermostatic expansion valve is to control the quantity of refrigerant in the evaporator coil, as well as to prevent any liquid refrigerant from reaching the compressor because the liquid refrigerant is non-compressable and can damage the compressor. After this, the refrigerant will flow to the evaporator where it will absorb heat from the air drawn by the evaporator blower.

- 11. ŌĆó A blower forces air from the interior of the car through the evaporator and circulate it to the interior of the car by means of the front grilles of the panel board of the evaporating unit. As the liquid refrigerant is absorbing heat inside the car compartment, the liquid refrigerant, will change to gas refrigerant and return through the suction line to the suction service valve, and the cycle is repeated.

- 12. ŌĆó The continuous cycle, once repeated, will very often drop the temperature in the car which could reach an uncomfortable level. To prevent this condition, a thermostat will open the magnetic clutch of the compressor to disengage and stop the cycle.

- 13. ILLUSTRATIONS

- 14. PURPOSE OF AIRCONDITIONING ŌĆó Temperature control ŌĆó Rehumidify ŌĆó Air purification ŌĆó Air circulation ŌĆó It conditions the air

- 15. ILLUSTRATIONS

- 16. PHASES OF MATTER ŌĆó SOLID- compact material ŌĆó LIQUID- a substance that does not expand. ŌĆó GAS- a substance with the capacity to expand. ŌĆó PLASMA- distinct state of matter. Described as an electrically neutral medium of positive and negative particles. Heating a gas may ionize its molecules or atoms (reducing or increasing the number of electrons in them), thus turning it into a plasma, which contains charged particles: positive ions and negative electrons or ions.

- 18. HEAT EFFECTS CHANGE OF STATE ŌĆó LIQUID ŌĆō HEAT = SOLID ŌĆó LIQUID + HEAT = GAS ŌĆó SOLID ŌĆō HEAT = SOLID ŌĆó SOLID + HEAT = LIQUID ŌĆó GAS ŌĆō HEAT = LIQUID ŌĆó GAS + HEAT = PLASMA ŌĆó PLASMA + HEAT = PLASMA ŌĆó PLASMA ŌĆō HEAT = GAS

- 19. UNIT OF HEAT ŌĆó BRITISH THERMAL UNIT (BTU) ŌĆō It is the amount of heat required to raised one pound of water to one degree fahrenheit. The more BTU a substance, the greater will be the total heat and vice versa.

- 20. METHODS OF HEAT TRANSFER ŌĆó CONDUCTION ŌĆó CONVECTION ŌĆó RADIATION ŌĆó In conduction, heat transfer occurs between objects by direct contact. In convection, the heat transfer takes within the fluid. In radiation, heat transfer occurs through electromagnetic waves without involving particles.

- 21. ILLUSTRATIONS

- 22. TYPES OF HEAT ŌĆó SPECIFIC HEAT- is the amount of heat required to raise the temperature of 1 lb of a substance to 1 ╦ÜF. It is also the amount of heat available to a specific substance. ŌĆó SENSIBLE HEAT- heat added to or removed from a substance without changing its state but changes occur in its temperature level.

- 23. ŌĆó LATENT HEAT- heat added to or removed from a substance without changing its temperature but its state changes. ŌĆó SUPER HEAT- temperature of a gas substance above its saturation change of state temperature

- 24. TEMPERATURE ŌĆó It is the measurement of the intensity movement of heat. The coldness and hotness of a material.

- 26. UNIT CONVERSION ŌĆó CONVERSION FORMULAS: -FAHRENHEIT TO CELSIUS; ╦ÜC=5/9(╦ÜF-32) -CELSIUS TO FAHRENHEIT; ╦ÜF=(9/5X╦ÜC)+32 TO GET ABSOLUTE TEMPERATURE; RANKINE(╦ÜR) = ╦ÜF +459 KELVIN (╦ÜK) = ╦ÜC +273

- 27. AUTHORS ŌĆó CELSIUS- Anders Celsius ŌĆó FAHRENHEIT- Daniel Fahrenheit ŌĆó RANKINE- William Rankine ŌĆó KELVIN- Lord Kelvin

- 28. FAHRENHEIT TO CELSIUS 212˚F TO ˚C ˚C=5/9(˚F-32) ˚C=.555(212-32) ˚C=.555(180) ˚C=100

- 29. CELSIUS TO FAHRENHEIT 100˚C TO ˚F ˚F=(9/5X˚C)+32 ˚F=(1.8X100)+32 ˚F=180+32 ˚F=212

- 30. KELVIN TO RANKINE 100˚K TO ˚R ˚K=˚C+273 ˚ F=(9/5X˚C)+32 ˚R=˚F+459 ˚C=˚K-273 ˚ F=[1.8X(-173)]+32 ˚R=-279.4+459 ˚C=100-273 ˚ F=-311.4+32 ˚R=179.6 ˚C=-173 ˚ F=-279.4

- 31. RANKINE TO KELVIN 100˚R TO ˚K ˚R=˚F+459 ˚C=5/9(˚F-32) ˚K=˚C+273 ˚F=˚R-459 ˚C=.555(-359-32) ˚K=-217+273 ˚F=100-459 ˚C=.555(-391) ˚K=56 ˚F=-359 ˚C=-217

- 32. KELVIN TO FAHRENHEIT 200˚K TO ˚F ˚K=˚C+273 ˚F=(9/5X˚C)+32 ˚C=˚K-273 ˚F=[1.8(-73)]+32 ˚C=200-273 ˚F=-131.4+32 ˚C=-73 ˚F=-163.4

- 33. FAHRENHEIT TO KELVIN 0˚F TO ˚K ˚C=5/9(˚F-32) ˚K=˚C+273 ˚C=.555(0-32) ˚K=-17.76+273 ˚C=.555(-32) ˚K=255.24 ˚C=-17.76

- 34. RANKINE TO CELSIUS 180˚R TO ˚C ˚R=˚F+459 ˚C=5/9(˚F-32) ˚F=R-459 ˚C=.555(-279-32) ˚F=180-459 ˚C=.555(-311) ˚F=-279 ˚C=-172.6

- 35. CELSIUS TO RANKINE 60˚C TO ˚R ˚F=(9/5X˚C)+32 ˚R=˚F+459 ˚F=(1.8X60)+32 ˚R=140+459 ˚F=108+32 ˚R=599 ˚F=140

- 36. KELVIN TO CELSIUS 150˚K TO ˚C ˚K=˚C+273 ˚C=˚K-273 ˚C=150-273 ˚C=-123

- 37. CELSIUS TO KELVIN 10˚C TO ˚K ˚K=˚C+273 ˚K=10+273 ˚K=283

- 38. RANKINE TO FAHRENHEIT 120˚R TO ˚F ˚R=˚F+459 ˚F=˚R-459 ˚F=120-459 ˚F=-339

- 39. FAHRENHEIT TO RANKINE 8˚F TO ˚R ˚R=˚F+459 ˚R=8+459 ˚R=467

- 40. PRESSURE ŌĆó It is the total force exerted on a surface. ŌĆó Formula: ŌĆó P=F/A ŌĆó F=P(A) ŌĆó A=F/P Where; P=Pressure (psi) F= Force (lb) A= Area (Sq. in.)

- 41. TO GET THE PRESSURE GIVEN: FORCE= 20lbs AREA= 10sq.in FORMULA: P= F/A P=20Pounds/10sq.in P=2Psi

- 42. TO GET THE FORCE GIVEN: PRESSURE= 2Psi AREA= 10sq.in FORMULA: F= P(A) F=2Psi(10sq.in) F=20Pounds

- 43. TO GET THE AREA IN A GIVEN PRESSURE GIVEN: FORCE= 20Pounds PRESSURE= 2Psi FORMULA: A= F/P A=20Pounds/2Psi A=10 sq.in

- 44. ILLUSTRATIONS

- 45. ATMOSPHERIC PRESSURE ŌĆó At sea level, the air with full height of the atmosphere is weighing 14.7 pound. Thus the pressure is 14.7 psi. At higher altitudes, there is less weight so the pressure is less. Below sea level, atmospheric pressure is more than 14.7 psi. any conditions where pressure is less than atmospheric pressure is called vacuum. A perfect vacuum is the complete absence of pressure.

- 46. ILLUSTRATIONS

- 47. AMBIENT TEMPERATURE ŌĆó It is the surrounding air temperature.

- 48. ATMOSPHERIC AIR ŌĆó Air surrounding the earth is called Atmospheric Air. ŌĆó Atmospheric air is a mixture of 23% of oxygen by weight and 75% of nitrogen by weight, and the other gasses which is composed of the remaining weight. These are the carbon dioxide, ozone, carbon monoxide and neon in small quantities. Moisture is water in the form of gas

- 49. RELATIONSHIP: PRESSURE AND TEMPERATURE ŌĆó Temperature and Pressure is directly proportional. When the pressure rises, the temperature also rises and vice versa.

- 50. LAWS OF THERMODYNAMICS ŌĆó Zeroth Law of Thermodynamics ŌĆó First Law of Thermodynamics ŌĆó Second Law of Thermodynamics ŌĆó Third Law of Thermodynamics

- 51. ZEROTH LAW OF THERMODYNAMICS ŌĆ£It state that temperature is the indicator of thermal equilibrium in the sense that there is no flow of heat between two substance in thermal contact that have the same temperature.ŌĆØ It is also called ŌĆ£THERMAL EQUILIBRIUMŌĆØ

- 52. FIRST LAW OF THERMODYNAMICS ŌĆó It is the expression of the Law of Conservation of Energy. ŌĆó It state the relationship between work, heat and changes in the internal energy.

- 53. SECOND LAW OF THERMODYNAMICS ŌĆó It states that heat travels from high temperature to low temperature of a substance.

- 54. ILLUSTRATIONS

- 55. THIRD LAW OF THERMODYNAMICS ŌĆó It state that it is not possible/impossible to lower the temperature of any substance to absolute zero (T=0╦ÜK) in a finite number of steps.

- 56. HUMIDITY - is the amount of water vapor in the air. Water vapor is the gas phase of water and is invisible. Humidity indicates the likelihood of precipitation, dew, or fog. Higher humidity reduces the effectiveness of sweating in cooling the body by reducing the rate of evaporation of moisture from the skin.

- 57. ŌĆó TYPES OF HUMIDITY 1. Absolute- is the water content of air. 2. Relative- is a function of both its water content and temperature. 3. Specific- is a ratio of the water vapor content of the mixture to the total air content.

- 58. PROCESS OF AIRCONDITIONING ŌĆó Process of compression ŌĆó Process of condensation ŌĆó Process of filtration ŌĆó Process of expansion ŌĆó Process of evaporation

- 59. AIR-CONDITIONING SYSTEM: PARTS ŌĆó BASIC PARTS OF THE A/C SYSTEM INCLUDES; 1. COMPRESSOR 2. CONDENSER 3. RECEIVER DRIER 4. EXPANSION VALVE 5. EVAPORATOR

- 60. A/C COMPRESSOR ŌĆó Also called as the ŌĆ£heart of the systemŌĆØ. ŌĆó It compresses the LP/LT gas refrigerant. ŌĆó It also circulates the refrigerant through out the system.

- 61. TYPES OF COMPRESSOR IN GENERAL USE A. Reciprocating B. Swash plate Other types; 1. Screw compressor 2. Rotary compressor 3. Centrifugal compressor 4. Scroll compressor

- 62. RECIPROCATING COMPRESSOR ŌĆó The reciprocating compressors are one of the most widely used types of the refrigerating compressors. They have piston and cylinder arrangement like the automotive engine. It has reed valves that control the entrance and exit of the refrigerant gas during the pumping operation. Schrader valves are mostly used for the service valves for easy connection.

- 63. DURING SUCTION STROKE ŌĆó When the piston is on the down stroke, the discharge reed valve is closed as well as the suction service valve until the piston reach the middle area of the cylinder to create vacuum and to lower the pressure inside the cylinder. The suction reed valves will open when the piston reach the middle area in the cylinder, then allowing the refrigerant to come in.

- 64. DURING DISCHARGE STROKE ŌĆó Wile the piston is on the upward stroke, the suction reed valve will close while the discharge reed valve will open when the piston reach the middle area of the cylinder to create compression, then allowing the refrigerant to come out of the cylinder.

- 66. SWASH PLATE COMPRESSOR ŌĆó It has an axial plate pressed to the shaft. Instead of a crankshaft, produces the reciprocating motion to the piston. The flow of incoming and outgoing refrigerant is controlled by the opening and closing of reed valves which are inside the compressor. There is one common suction port and one common discharge port in the compressor.

- 67. ILLUSTRATIONS

- 69. MAGNETIC CLUTCH ŌĆó The main purpose of the magnetic clutch is to engage and disengage the compressor from the engine. It has a drive belt pulley which is connected to the engine.

- 70. COMPRESSOR OIL ŌĆó Is necessary to lubricate the seal, gasket and other moving parts of the compressor. A small amount of oil is circulated through the system with refrigerant. Only non-foaming oil specially formulated for use in each car airconditioner should be used. The oil act as a lubricating agent and a coolant in the compressor.

- 71. ŌĆó Refrigeration oil is highly refined, it is mineral oil with all impurities such as wax and sulphur. Never use any kind of motor oil except those oil recommended by the manufacturer.

- 72. A/C CONDENSER ŌĆó The purpose of the condenser is to receive the high- pressure gas refrigerant from the compressor and change it to liquid by discharging heat into the atmospheric air. It is the principle that heat flows from warmer to a cooler substance. The greater the amount of heat given of in the condenser, the greater will be the cooling effect attainable by the evaporator. It is installed usually at the front end of the car radiator to enable forcible cooling by the air drawn in the engine radiator fan and the air stream created by the running of the car.

- 73. TYPES OF CONDENSER 1. Air-cooled ŌĆō air-cooled condenser have two basic types: Ram Air and the Forced air condenser. 2. Water cooled- Not common used in A/C system, mostly at bigger size refrigeration. A. Ram air condenser depend upon car movement to force a large of air pass the aluminum fins and coils of the condenser. The engine blower is used to increase air volume at lower speeds.

- 74. The clutch-type blower is designed to allow the blower blades to free-wheel at higher speeds to eliminate blade drag. At lower speeds, the blower fan clutch will engage the fan to increase air flow over the condenser and radiator coils. B. Forced air condenser are usually used for off-the -road units. It uses blower fan to move a large volume of air over the condenser.

- 76. ILLUSTRATIONS

- 78. A/C RECEIVER DRIER PARTS & FUNCTIONS The receiver-drier is divided into three parts: the receiver, the drier and the sight glass. 1. The receiver section - is a storage compartment that accepts the proper amount of refrigerant. 2. The drier section ŌĆō is simply a bag of desiccant; such as silica gel, a chemical that absorbs and holds small quantities of moisture that can damage the system. 3. The sight glass section ŌĆō is provide to check if the amount of refrigerant charged to the system is enough. If the vapor bubbles appear in the sight glass this is an indication of the lack of refrigerant.

- 79. ILLUSTRATIONS

- 81. FUSIBLE PLUG The fusible plug protects from damage of the other parts in the system when the temperature and pressure inside the condenser or receiver go up abnormally because of poor radiation of the excessive heated components. The fusible plug is soldered wherein it will melt at the temperature of 212 to 350 degrees fahrenheit.

- 82. A/C EXPANSION VALVE ŌĆó Is a metering device that lowers the temperature of the liquid refrigerant from the condenser. The orifice tube of the expansion valve sprays out the high pressure liquid refrigerant from the condenser to the evaporator, thus lowering the pressure. Expansion valves are classified into two; internally equalized and externally equalized.

- 83. ILLUSTRATIONS

- 84. A/C EVAPORATOR ŌĆó Evaporator is just an opposite of the condenser. If the condenser discharges heat and converts the gas refrigerant into liquid, the evaporator absorbs heat and converts the liquid refrigerant into gas. The evaporator absorbs heat inside the compartment of the car thus cooling it on the level of human comfort.

- 85. ŌĆó As the evaporator absorbs heat, the 100% liquid refrigerant sprayed by the expansion valve to the evaporator is converted to 100% gas refrigerant that is induced to the compressor. If too much refrigerant is sent into the evaporator, it will not cool normally because the pressure of the refrigerant will be higher and it will not boil easily.

- 86. ŌĆó If little refrigerant is supplied into the evaporator, it is referred to as starved evaporator. This condition will not normally cool because the refrigerant will boil off, long before it passes through the evaporator.

- 87. ILLUSTRATIONS

- 88. A/C BLOWER FAN ŌĆó The fan motor or the blower fan forces the passenger compartment of the car through the evaporator and circulates it to the interior of the car by means of the grills. The motor input of the fan blower ranges from 60W to 150W.

- 89. ILLUSTRATIONS

- 90. ACCUMULATOR ŌĆó Located between evaporator and compressor (low side) ŌĆó Primary function is to separate the vapor from the liquid and oil.

- 91. REFRIGERANT LINES AND CONNECTIONS ŌĆó Suction line- Evaporator outlet to compressor inlet. ŌĆó Discharge line- Compressor outlet to condenser inlet. ŌĆó Liquid line- Receiver drier outlet to thermostatic expansion valve.

![KELVIN TO RANKINE

100˚K TO ˚R

˚K=˚C+273 ˚ F=(9/5X˚C)+32 ˚R=˚F+459

˚C=˚K-273 ˚ F=[1.8X(-173)]+32 ˚R=-279.4+459

˚C=100-273 ˚ F=-311.4+32 ˚R=179.6

˚C=-173 ˚ F=-279.4](https://image.slidesharecdn.com/hvac-240603142140-e77ff562/85/HVAC-ppt-heating-ventillation-and-air-conditioning-30-320.jpg)

![KELVIN TO FAHRENHEIT

200˚K TO ˚F

˚K=˚C+273 ˚F=(9/5X˚C)+32

˚C=˚K-273 ˚F=[1.8(-73)]+32

˚C=200-273 ˚F=-131.4+32

˚C=-73 ˚F=-163.4](https://image.slidesharecdn.com/hvac-240603142140-e77ff562/85/HVAC-ppt-heating-ventillation-and-air-conditioning-32-320.jpg)

![[1] Introduction to Refrigeration Systems_removed.pdf](https://cdn.slidesharecdn.com/ss_thumbnails/1introductiontorefrigerationsystemsremoved-250209055201-82af8ab5-thumbnail.jpg?width=560&fit=bounds)