Hvm10th phil o'donovan

- 1. HVM: A Suitable Model for the UK Dr Phil O’Donovan Chairman, Twelve Winds 10th Anniversary High Value Manufacturing Conference http://www.hvm-uk.com Murray Edwards College Cambridge 14th November 2012 © Twelve Winds Ltd 2012 1

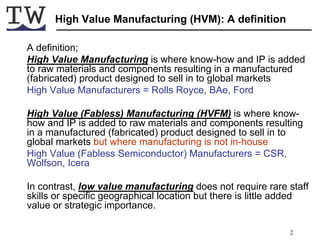

- 2. High Value Manufacturing (HVM): A definition A definition; High Value Manufacturing is where know-how and IP is added to raw materials and components resulting in a manufactured (fabricated) product designed to sell in to global markets High Value Manufacturers = Rolls Royce, BAe, Ford High Value (Fabless) Manufacturing (HVFM) is where know- how and IP is added to raw materials and components resulting in a manufactured (fabricated) product designed to sell in to global markets but where manufacturing is not in-house High Value (Fabless Semiconductor) Manufacturers = CSR, Wolfson, Icera In contrast, low value manufacturing does not require rare staff skills or specific geographical location but there is little added value or strategic importance. 2

- 3. Case study: CSR plc CSR is a global fabless semiconductor manufacturing business based in Cambridge; Raised $85M pre-IPO From start-up in April .99 to flotation on the LSE in March .04 Joined FTSE 250 in July .04 Global technology brand and Bluetooth market leader From 9 founders to more than 1,000 staff across the world 2006 revenue of $700M and market cap around $1B Shipped more than 1,000,000,000 chips in first 7 years. 3

- 4. BlueCoreTM: A truly disruptive product BlueCoreTM Single Chip Wireless in CMOS; Baseband Software Some Design Issues • Weak analogue and strong digital signals • On silicon frequency planning • Uncharacterised CMOS at 2.4GHz • Very small footprint required • Package choices:- fpBGA and WLCSP • Tight hardware / software coupling Radio Microprocessor • Testability and reprogrammability. 4

- 5. The HVM business model IP & Know-how Manufacturing Drop-shipping Expertise Testing Support Design Packaging Returns Manufacturing £££ Depth of Manufacturing Fabless Expertise Manufacturing ££ Needed and Generated Design Services £ 5

- 6. HV Fabless Manufacturing (HVFM) The HV Fabless Manufacturing model is not for the faint-hearted; standard (not custom) product comfort zone Survival & Success Entry Barriers Right Product Factors Raising enough cash Industry standards IP management Design for test and Driving legislation Apps engineers manufacture Market need Design partners Gaining attention of fabs Innovative design Driving down GPM Right first time design Being in the manufacturing loop Developing multiple product families Most fabless (semiconductor) manufacturing companies fail because they underestimate entry barriers and survival & success factors. 6

- 7. HV Fabless Manufacturing benefits to the UK Why has HVFM succeeded in the UK; Educated workforce Attractive place to live Manufacturing legacy Attractive tax regime for entrepreneurs ? Benefits that HVFM companies provide UK plc include; Jobs Tax revenue Generation and retention of IP and manufacturing expertise. 7

- 8. Increasing the UK HVM base What can be done to encourage HVM in the UK ? Education: Schools (teach computing) Universities (more blue sky research, less development) Fraunhofer Institutes (link universities to industry) Tax for start-ups: Simple, founder & staff-friendly and stable Industry and government: Patent treaty enforcement Brand anchoring Government UK purchasing policy National industrial strategy ? 8