Hydraulic braking system.pptx

- 2. Efficient Braking Hydraulic braking systems are the most common type of braking system used in vehicles today.This presentation will explore the components and functionality of these systems,as well as techniques for optimizing their performance.

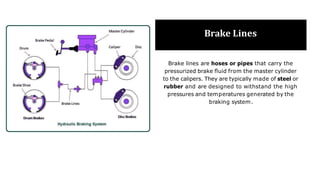

- 3. The Basics Hydraulic braking systems use ’¼éuid pressure to convert the force of the driver's foot on the brake pedal into friction between the brake pads and the rotors.The main components of a hydraulic braking system include the master cylinder,brake lines, calipers,and pads.

- 4. Master Cylinder The master cylinder converts the force from the brake pedal into hydraulic pressure.It contains a piston that moves in response to the force applied to the pedal.This piston pressurizes the brake ’¼éuid,which is then sent through the brake lines to the calipers.

- 5. Brake Lines Brake lines are hoses or pipes that carry the pressurized brake ’¼éuid from the master cylinder to the calipers. They are typically made of steel or rubber and are designed to withstand the high pressures and temperatures generated by the braking system.

- 6. Calipers Calipers are the components that clamp the brake pads onto the rotors. They contain pistons that move in response to the hydraulic pressure from the master cylinder. This movement causes the brake pads to squeeze the rotor,generating friction and slowing the vehicle.

- 7. Pads Brake pads are replaceable components that press against the rotors to generate friction. They are typically made of ceramic,metallic,or organic materials and are designed to withstand the high temperatures and pressures generated by the braking system.

- 8. Optimizing Performance There are several techniques for optimizing the performance of hydraulic braking systems.These include upgrading to high- performance brake pads,venting the brake system to reduce heat buildup, and installing larger rotors to increase surface area.

- 9. Maintenance Proper maintenance is essential for the longevity and performance of hydraulic braking systems.This includes regular inspections of the brake pads,rotors, and ’¼éuid levels,as well as ’¼éushing and bleeding the brake system to remove air and debris.

- 10. Safety Hydraulic braking systems are critical for vehicle safety. It is important to maintain these systems properly and replace any worn or damaged components as soon as possible. Always follow proper braking techniques and allow suf’¼ücient stopping distance to avoid accidents.

- 11. Conclusion Hydraulic braking systems are essential for safe and ef’¼ücient vehicle operation. Understanding the components and functionality of these systems, as well as techniques for optimizing their performance,can help drivers and mechanics maintain their vehicles and stay safe on the road.