I4MS Talk "Industry 4.0 & the integrated environment" presentation

- 1. Valerio Alessandroni EFCC - Estonian Fieldbus Competency Centre I4MS Ambassador Industry 4.0 and the integrated environment 24 February 2021

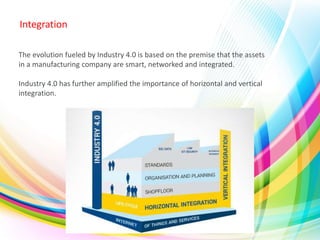

- 2. The evolution fueled by Industry 4.0 is based on the premise that the assets in a manufacturing company are smart, networked and integrated. Industry 4.0 has further amplified the importance of horizontal and vertical integration. Integration

- 3. Delayed orders donŌĆÖt allow an ideal or demand- based production Unforeseeable events canŌĆśt be immediately considered in the production program Uncertainty in communication leads to misunderstandings and inefficient workflows Adjustments of the production program require high costs or efforts Misunderstandings Delayed orders Ineffective PP Low flexibility Issues in traditional manufacturing companies

- 4. Horizontal and vertical integration ŌĆ£Horizontal integrationŌĆØ means that all objects, departments and all companies within the network exchange data reciprocally ŌĆ£Vertical integrationŌĆØ ties together all logical layers within the organization from the production floor up through R&D, quality assurance, product management, IT, sales and marketing, and so on. Data can flow freely and transparently up and down these layers so that decisions can be data-driven.

- 5. Horizontal and vertical integration

- 6. Benefits of horizontal integration Always-connected machines and production units each become an object with well-defined properties within the production network. They can constantly communicate their performance status and autonomously respond to changing production requirements.

- 8. Horizontal integration in the supply chain Horizontal integration involves all parts of the supply chain. The partners are connected by a network of information sharing such as machine maintenance, or the supply of raw materials: in real time the supplier can be notified of the supply need of a raw material; or a machine supplier can communicate a whole series of information, through the cloud, which allows the company to better manage the maintenance. Horizontal integration can also reach the customer.

- 9. Horizontal integration This deeper alignment improves visibility, flexibility, and productivity while also enhancing levels of automation.

- 10. Vertical integration Industry 4.0 vertical integration connects all business units and processes within the organisation. In other words, converging operational technology (OT) at the production level with information technology (IT) at the enterprise level. Data flows between and is made available to all business units, including the factory floor, marketing, sales, customer service, purchasing, accounting, HR, quality control, R&D, and more.

- 11. Vertical integration A system is defined as vertically integrated if it manages to involve more subjects, starting from the base (for example the production lines) up to the upper levels of the management. In this way the information rapidly crosses all the subjects involved, reducing the dead times that usually exist between the acquisition of the data and the decision- making moment.

- 14. Integration: business and technology standpoints

- 15. Integration

- 18. Cloud based integration Integration based on service oriented cloud platform

- 19. Horizontally vs vertically integrated company A horizontally integrated company focuses its activities around its core competencies and establishes partnerships to build out an end-to-end value chain. A vertically integrated company keeps as much of its value chain in-house as it canŌĆöfrom product development to manufacturing, marketing, sales, and distribution.

- 20. Horizontally vs vertically integrated company

- 21. Conclusion Horizontal integration is the acquisition of a business operating at the same level of the value chain in the same industry. Other goals include increasing in size, creating economies of scale, increasing market power over distributors and suppliers, increasing product or service differentiation, expanding the company's market or entering a new market, and reducing competition. from Wikipedia

- 22. Conclusion Vertical integration is a strategy whereby a company owns or controls its suppliers, distributors or retail locations to control its value or supply chain. Vertical integration benefits companies by allowing them to control process, reduce costs and improve efficiencies. from Wikipedia

- 23. Conclusion While horizontal integration and vertical integration are both ways that companies grow, there are important differences between the two strategies. Vertical integration occurs when a business owns all parts of the industrial process while horizontal integration occurs when a business grows by purchasing its competitors

- 24. Thank you!

Editor's Notes

- #3: Herk├Čmmlicher Ablauf der Implementierung von Systemen Dauert Monate Ben├Čtigte: Anforderungsanalyse Informationsnachfrage Lastenhefterstellung Make or Buy Entscheidung Implementierung und Einkauf oder Erstellung Stabilisierung/Optimierung Abnahme Ergebnis ist eine wenig flexible, komplette und kostenintensive L├Čsung

- #4: Herk├Čmmlicher Ablauf der Implementierung von Systemen Dauert Monate Ben├Čtigte: Anforderungsanalyse Informationsnachfrage Lastenhefterstellung Make or Buy Entscheidung Implementierung und Einkauf oder Erstellung Stabilisierung/Optimierung Abnahme Ergebnis ist eine wenig flexible, komplette und kostenintensive L├Čsung